RUC Keynote: Jeff Burnstein Kicks Off With a Cobot Market Mystery

Posted on Sep 05, 2018 2:59 PM. 4 min read time

The RUC started with some surprising news from A3's Jeff Burnstein: we don't know how big the cobot market is! Here's what he covered in the first keynote of the day.

What a start to the first day of the The Robotiq User Conference! We've had some spectacular sessions this morning, starting with the one of the biggest names in industrial robotics: Jeff Burnstein from A3.

In his keynote this morning, Jeff revealed that we don't how big the collaborative robot market is… and that he once almost lost his hand to a cobot.

Meet Jeff Burnstein

Jeff Burnstein is the President of A3. He has worked for over 30 years to promote the use of robotics and other automation technologies.

If you're not familiar with A3, here's the lowdown. The Association for Advancing Automation (A3) is THE global advocate for the benefits of automating. They are an umbrella association for other leading bodies in robotics, including RIA, AIA and MCMA. They make it their business to promote automation technology to businesses around the world. Jeff has also advised congress.

An attendee at Automate 2017 from Jeff's final video explained A3's role perfectly

"The A3 really pulls together a lot of different technologies that are needed for automation, and they represent it really, really well."

We don't know how big the market for cobots is!

One surprising fact that Jeff revealed during his keynote is that the size of the cobot market is really a mystery right now.

He said:

"How big is this market? We know it's growing quickly. We really don't know what the numbers are. Neither the IFR or the RIA is able to collect enough data to separate out the collaborative robot market."

He went on to compare some of the studies which attempt to put numbers on the market:

- One study estimated we'll have 40,000 cobots and $1 billion in revenue by 2020.

- Another estimated a total market of $9 billion by 2025.

- Another estimated a market estimated $4.2 billion by 2023.

Jeff isn't concerned by these contradictory estimates because we can tell that the market is growing. We can tell because there is a rising number of cobot-targeted products products, new cobot manufacturers, and cobots from traditional industrial manufacturers.

The market is growing, we just don't know by how much.

The big issues: Safety and impact on jobs

The two main cobot issues that Jeff touched on in his keynote were ones which we have covered here on the Robotiq blog many times: safety and impact on jobs.

Safety: Jeff almost loses a hand

Jeff was very clear that safety is key issue for cobots. It's as important as it is for traditional industrial robots.

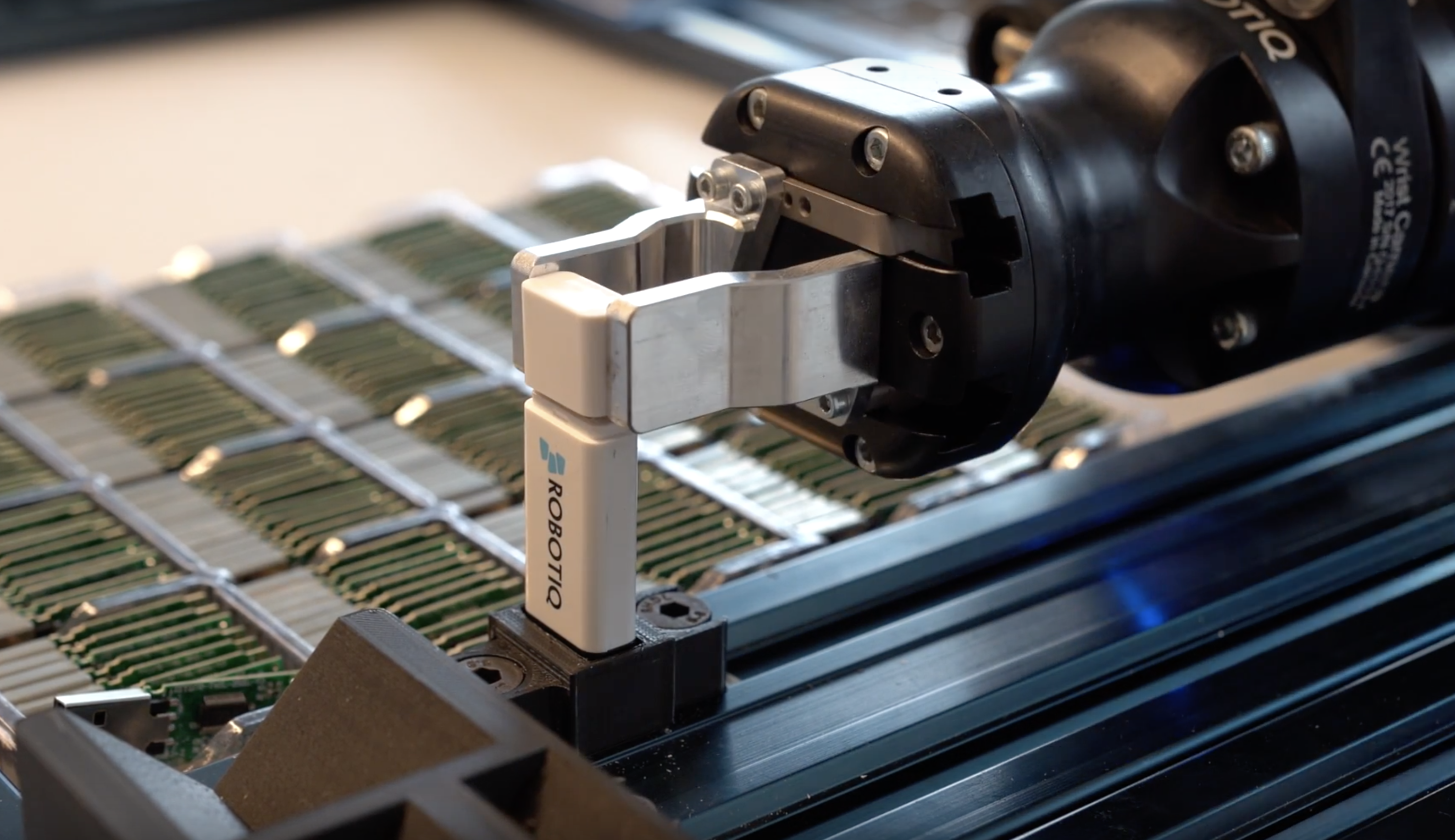

Although cobots are designed to not to cause harm if they collide with a person, that doesn't mean they are inherently safe. As he said:

"A cobot won't hurt you if it hits you. That's true, in most cases, but not if its holding a knife. If you're side by side with people you don't want somebody getting their eye poked out. So, risk assessment is probably the most critical thing."

We certainly agree! (that's why we wrote a step-by-step guide to risk assessment for cobots).

He also told a personal story which clearly demonstrates that cobots are not always inherently safe:

"I was at a company that made a collaborative robot and they said to me 'put your hand between the robot and the floor.' So I did and they said 'You'll see. It'll come down and it won't hurt you. It will move away once it makes contact.'

I thought when it hit me that it was just going to pull back. But it pressed my hand to the point that I thought I might not be able to use my hand ever again."

Inherently safe? Usually, but you still have to be careful.

Impact on jobs: Robots vs unemployment

Jeff also addressed the hot topic: do robots take jobs?

He revealed one fascinating correlation from a study A3 had conducted of the last 20 years:

"Whenever robot sales went up, unemployment went down. Whenever robot sales went down, unemployment went up. Does that sound like a job killer to you? Because it certainly doesn't to me."

Jeff also noted that the media often says "by 2030 there's going to be 800 million jobs lost."

But, the same study that created these figures showed that 900 million jobs would be created in the same time. That's a net gain of 100 million jobs. As Jeff pointed out, that second statistic is hardly ever mentioned in the media.

He listed three factors which are real threat to jobs:

- Inability to compete — The real threat to jobs is when companies go out of business. The reason that businesses fail is an inability to compete. He mentioned the case studies available at a3automate.org which show companies actually using automation to avoid going out of business.

- Focusing on fears means we miss out on opportunities — By fixating on the negative impacts of any technology (e.g. killer AI overlords), we could miss out on the benefits of that technology (e.g. AIs finding cures for cancers)

- The skills gap is real — There is a real lack of workers for particular posts. By 2025, 2 million jobs could be unfilled in manufacturing alone. Robots are one way to fill that gap

A3's Automate 2019 Conference

Jeff took the opportunity to tell us about the Automate conference which will be held in Chicago on the 8th to the 11th of April 2019.

Leave a comment