How to Optimize the Productivity of Existing Equipment

Posted on Mar 26, 2018 7:00 AM. 2 min read time

Manufacturers are constantly looking for new ways to increase production while maintaining (or decreasing) their current costs. But the best solutions can often be the most difficult to find. Robotiq's eBook Optimizing the Productivity of Existing Equipment is designed to help you better seek these solutions, so you can increase production without breaking the bank.

Join us as we look at the best ways to optimize your productivity, while keeping prices where you want them. This eBook, and many others, can be found on the Robotiq website.

What are the best ways to optimize productivity?

This eBook begins by looking at the variables that go into maximizing productivity. These variables fall into six categories:

● Cost of raw material

● Labor cost

● Machine runtime

● Quality control

● Production layout

● Energy consumption

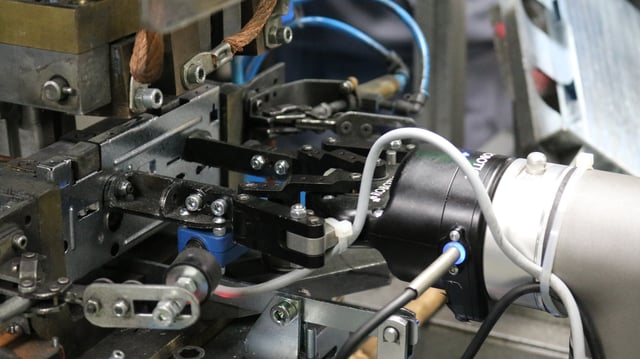

The first major thing to be considered is labor cost. Here, the eBook presents a ratio of task value/labor cost to define the value of specific tasks in your plant. Instead of seeking cheaper labor, companies should look for simple, labor-intensive tasks – such as an operator feeding parts to a machine – that can be automated with a collaborative robot solution.

Of course, adding robots is something that makes many workers feel uncomfortable. They often fear that the robots will replace them and their jobs. This is an understandable, but ultimately unfounded concern. Instead, robots should be perceived as a source of added value for the employee.

Human workers can be put in charge of the robot and become involved in surrounding tasks. Of course, there should be a balance between the value workers add and their compensation. As you search for new tasks to automate, you might consider bringing in experts to help you decide which ones will work best for the bottlenecks in your current process.

Next, the eBook looks at machine runtime. You should look at the maximum runtimes for your machines, to make sure you get the desired return on your investment. Ask yourself questions like these:

● How long does the machine run each day?

● How much machine downtime is there for repairs and maintenance?

● Does the operator make the machine work faster or slower?

Next up are the sections on quality control, production layout, energy consumption, and cost of raw materials. The eBook goes into equally deep detail on these subjects as well. It's a treasure trove of information and best practices for those who seek the “holy grail” that most factories want.

Optimization is about more than just material and machine spending. It comes down to a focus on resource utilization, process optimization, and getting more value from both machines and workers.

All these topics are covered in this free eBook. Have you read it? Let us know how you liked it in the comments!

Leave a comment