How a Manufacturer Doubled Capacity with Robotics

Posted on Mar 02, 2016 7:00 AM. 1 min read time

We love hearing about companies using robotics in real life. For Whippany Actuation Systems, the story starts with a need for more capacity. Faced with the choice of buying a second CNC machine or using robotics, Whippany chose to go with a collaborative robot or cobot for short.

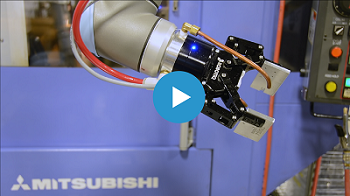

Whippany uses their robot and Gripper to load and unload parts from a CNC machine. It's setup so that it can run unattended - in fact, with robotics, Whippany was able to add a second shift on the CNC machine without needing to have someone onsite to babysit the setup.

The factory worker sets up the unprocessed parts at the beginning of the shift and the robot takes care of the rest: opening the CNC machine door, loading the part, closing the door, and at the end of the machining cycle, unloading the processed part and loading a fresh unprocessed part.

Get the full story and watch the video here.

For Whippany, introducing automation into their production process has allowed them to get more productivity out of their already existing, expensive equipment. This improves their margins, increases their competiveness and has also helped shorten their delivery lead times.

In fact, Whippany is so impressed with their robotic cell that they are looking at two new cells to automate in the coming year.

Leave a comment