Case Study: Robotiq FT 150 Sensor In Robotic Product Testing

Posted on Feb 16, 2015 3:59 PM. 6 min read time

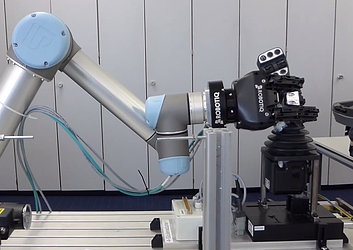

The Robotiq FT 150 force torque sensor can be used in a lot of applications. From assembly tasks to collaborative uses, the sensor is designed for a very wide range of applications. With the constant quest to bring products with high quality standards to the market, industrial applications have been interested in the use of the FT 150 sensor for quality assurance. Here's how a a leading manufacturer of operator controls, non-contact sensors and safety devices is using the Robotiq sensor in its manufacturing loop.

Application

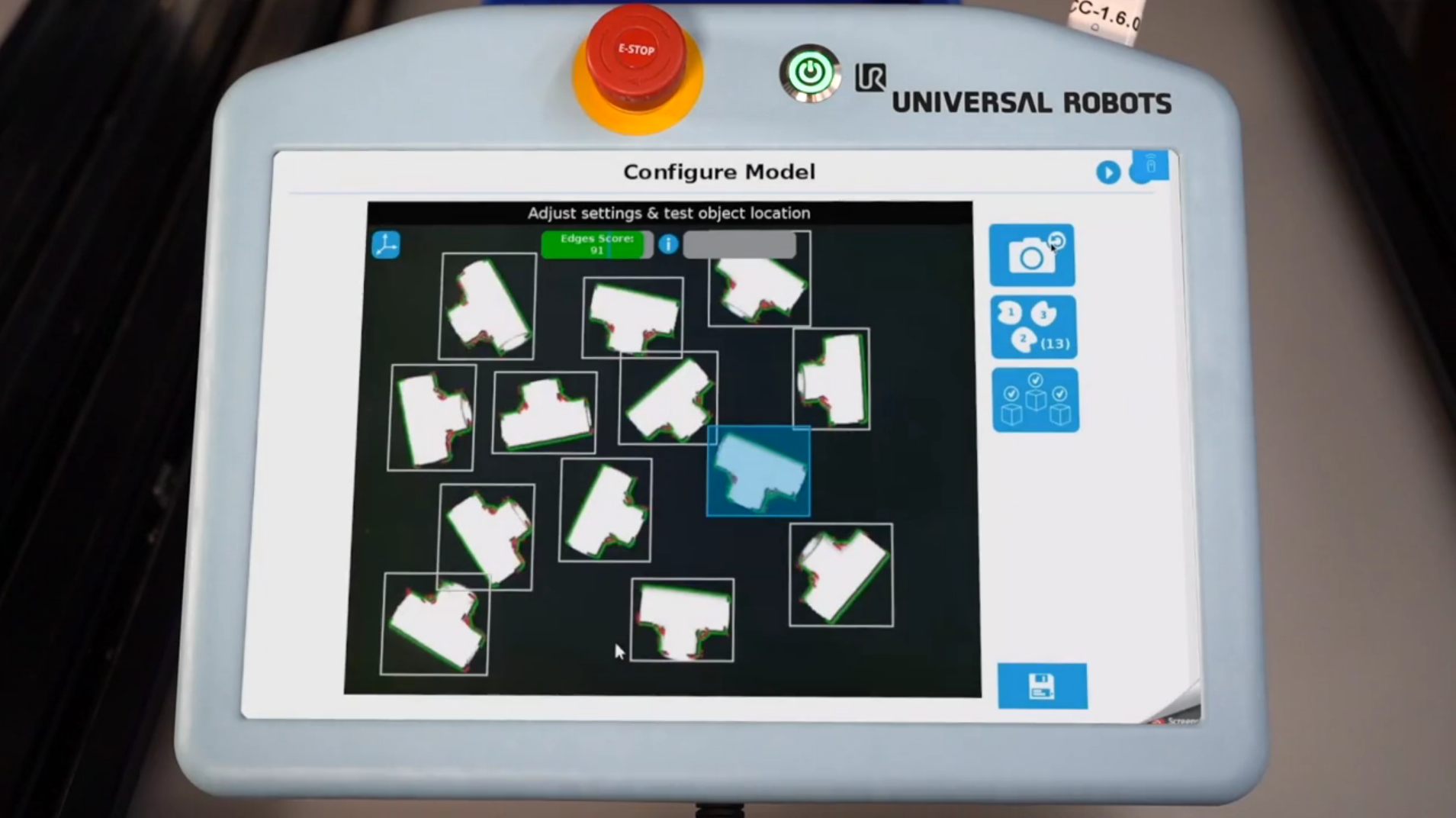

The joystick bases and control sticks are a main product group from a leading manufacturer of operator controls, non-contact sensors and safety devices. These products must go through a wide variety of qualitative and quantitative test procedures. The joysticks are sold by the manufacturer as a principle control device for vehicles and it is a critical component for their customers. The quality assurance team has to verify the conformance of the electronic and mechanical components before they get to final packaging. The quality control team in the past used to test their production manually which allowed the workers to adapt their verification tasks to dozens of different joystick models including custom configurations.

The goal was to monitor the performance, full functionality and sensitivity of the joystick components. With everything being done manually, the company strove to minimize the work-in-progress at the different workstations, but didn't want to jeopardize its quality by implementing random sampling. Over the long term, they couldn't afford to assign more workers or increase the production pace which might lead to worker fatigue and increased mistakes. These non-value added operations within their quality control functions represented the perfect opportunity for their quality and engineering team to automate their testing through the addition of a robot and gripper. Here's a demonstration how the cell works.

Devices

The goal was to have the most flexible robotic cell they could have. From this optic, they could test a very wide range of products with the same cell. Besides that, they wanted to have easy to integrate and easy to use devices that would all mesh together. Here is how they built their cell.

Robotiq - FT 150 Sensor

The starting point was to monitor the force applied on the joysticks with a device that is reliable and that was immune to the external noise. First, the FT 150 met the application requirements because it is precise (Effective Resolution 0.2 N), repeatable (Signal Noise 0.5 N) and can detect and direct a wide range of force (+/- 150 N). As the manufacturer needed to apply forces up to 100 N with low increments in all 3 axes, the force range was ideal for this application.

Since they are testing electronic devices, external noise due to electronic signaling is a concern when it's time to use a force torque sensor. With most brands using a force gauge to determine the force applied on the tool, Robotiq is using another technology to immunize the sensor from ambient noise. The manufacturer thought this was particularly good argument in favor of the FT 150, since it would improve their results by eliminating the possibility of interference from stray electronic noise.

Robotiq also provides an all-inclusive bundle to fit on Universal Robots (UR 5 and UR 10). This bundle contains the mechanical kit necessary for the UR5 or 10, including the required wiring and software to easily integrate the sensor with the robot.

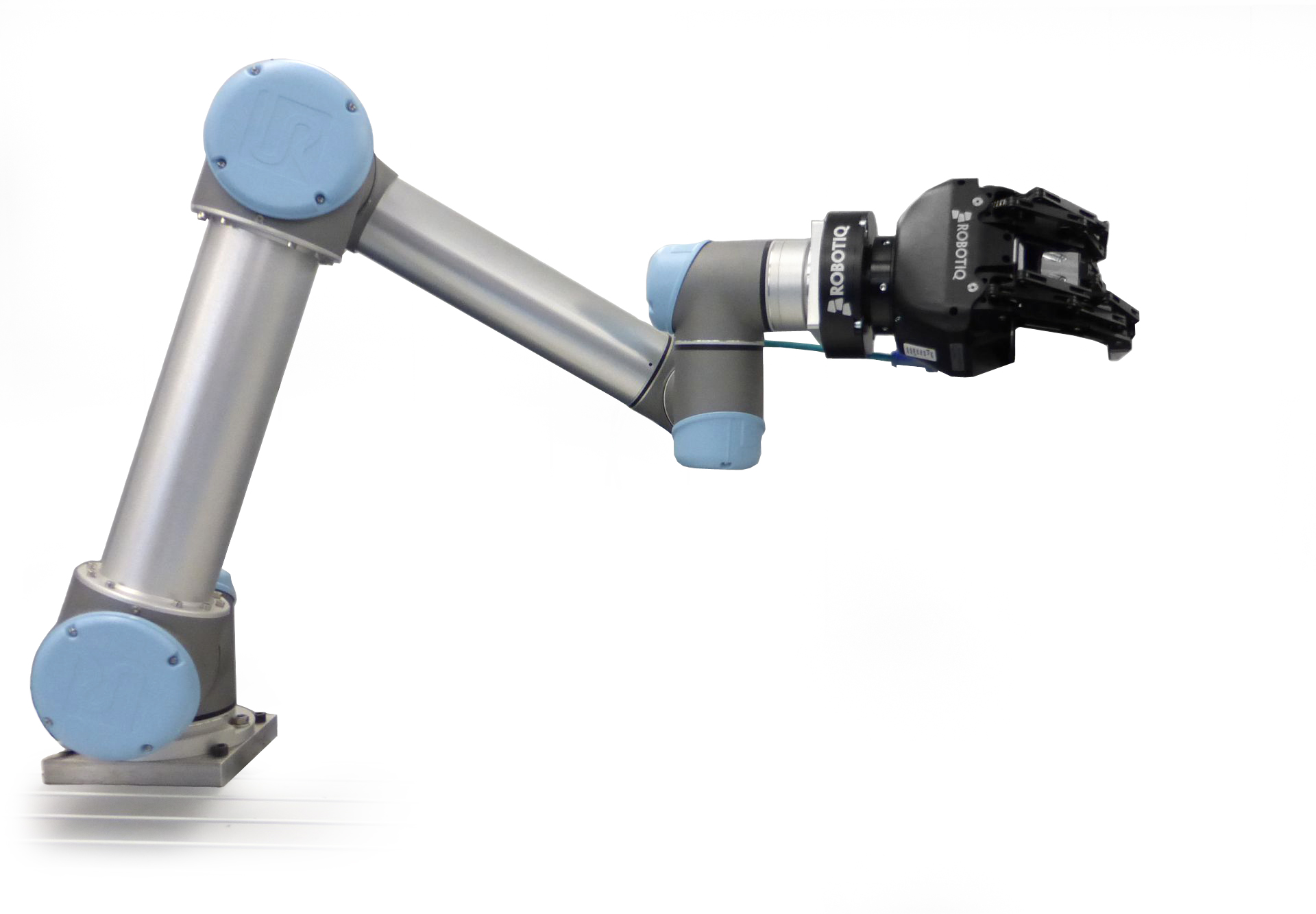

Robotiq - 3-Finger Adaptive Gripper

Flexibility! In fact, the 3-Finger Adaptive Gripper can be adapted to different situations with minimal setup time. The 3 fingered Gripper allows for a solid grip on the joystick, but can also adapt to different joysticks sizes and shapes. Considering the fact that the company is testing a wide range of product, they didn't wanted to have to adapt a gripper for each size/model they were testing. They also consider the fact that the 3-Finger Gripper is easy to integrate with the FT 150 sensor. The Gripper's payload is 10 kg and has a repeatability of 0.05mm.

Universal Robots - UR 10

.jpg?width=195&name=product_testing_sensor_gripper_(1).jpg)

Once again flexibility was part of the equation. The UR 10, as its name implies, can handle up to 10 kg and can be programmed by hand-guiding, so it doesn't need any fencing. The manufacturer thought this was a good approach for them. As the products tested come in different sizes and weights, they decided to play it safe going with a robot that can handle a slightly bigger payload than necessary. The fact that the robot can be used alongside people and can be programmed by hand-guiding fits the company's motto: ''Focus on people". Since with this collaborative robot fencing is not needed for the robotic cell and it is possible for workers to work around the robot without any risk. The speed and repeatability of the robot also conformed to the manufacturer's application.

This was just a short overview of the details of the robotic product testing cell. To read more, take a look at the case study at the bottom of this blog post.

Robotiq

Our goal is to enable all manufacturers — especially those dealing with high mix production — to take full advantage of robotics. We work with robot manufacturers, system integrators and end-users to automate applications that require flexibility. Robotiq sells product in more than 30 countries, through our global network of partners.

Leave a comment