Industrial Dexterous Robot Gripper Launched at Automate 2011

Posted on Mar 17, 2011 6:55 AM. 3 min read time

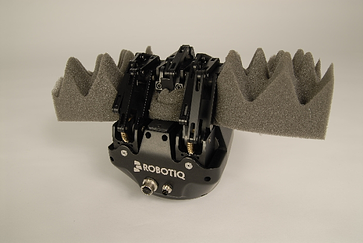

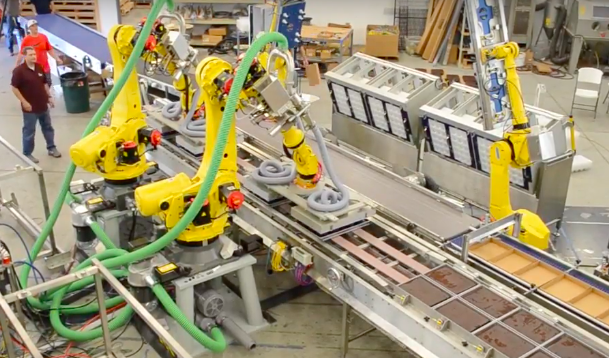

Recent years have been challenging for the North American manufacturing industry and momentum is picking back up. While it is still fresh in their memories, manufacturers are more conscious than ever that they must reduce costs while also increasing the flexibility of their processes to react faster to market changes. It is in this context that Robotiq launches the Adaptive Gripper at Automate 2011. The Gripper is the world’s first industrial dexterous gripper that gives industrial robots “hand-like” capabilities to enhance their ability to manipulate a wider variety of parts, detect a grip and control pressure on a given part.

“Applications with a very high number of different parts are challenging to automate if using today’s current one part / one tool approach. Tooling gets complicated, and changing grippers increases cycle time and lowers Return-on-Investment. As such, many of these applications are still performed with human operators.” explains Erik Nieves, Director of Technology for Motoman Robotics. Motoman is a Robotiq partner which will be distributing the Adaptive Gripper.

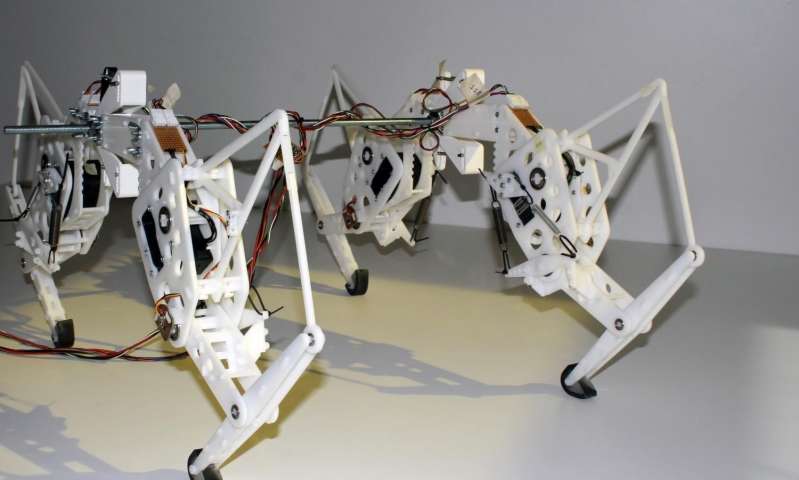

“Everyone has seen humanoid robots with human-like hands in the media. There are many of these hands out there, but the majority of them have been confined to the research market. Even if their flexibility is interesting, they are often too complex and fragile which makes them impossible to use in an industrial environment.” explains Robotiq’s CEO Samuel Bouchard. The Robotiq Adaptive Gripper is the first dexterous gripper that is rugged and simple enough to bring required grasping flexibility to today’s manufacturing settings. The Gripper is focused on applications that have a very high parts handling variety and complexity of parts geometry. Examples of applications are in: assembly, parts transfer, machine tending or parts positioning in welding.

The technology has been in development and testing for the past two years. It will be launched officially at the Automate 2011 show held in Chicago from March 21st to 24th, where it will be displayed on various partner’s robots.

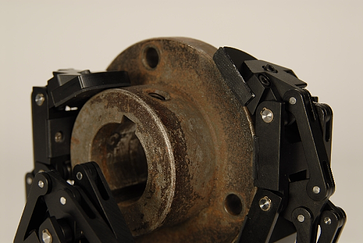

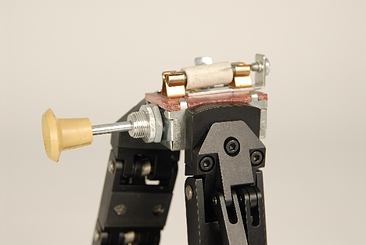

The gripper can control the pressure it exerts on a part and detect finger contact with a part.

Articulated fingers conform to the shape of a part.

Small parts can be picked up delicately from the fingertips. Partial closing and opening is also possible.

About Robotiq

Robotiq is a robot components manufacturer based in Quebec City, Canada. It is a privately funded company founded in 2008.

For more information, contact:

Pamela Rasey, Director of Marketing

1-888-ROBOTIQ (762-6847) ext.111

pamela@robotiq.com

Leave a comment