The Robots that Proctor & Gamble Dream About

Posted on Jan 28, 2011 10:39 AM. 2 min read time

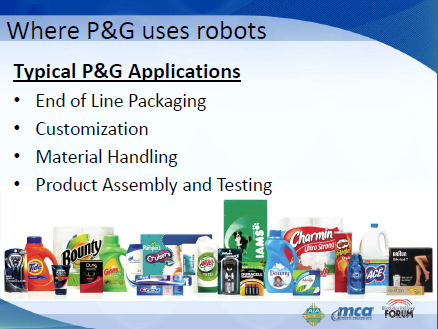

[Slide from P&G presentation at 2011 Robotics Industry Forum]

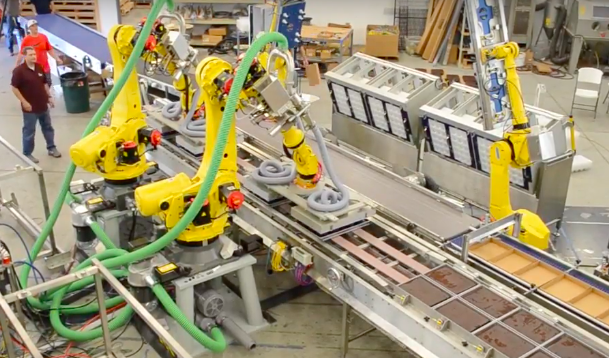

I had the chance to attend the 2011 Robotics Industry Forum event last week in Orlando, FL. One of the most interesting presentation was done by Mark Lewandowski, Machine Controls Technology Leader at Proctor & Gamble. The presentation created a unique setting whereby this extremely large company was telling an entire industry: "Guys, I am very willing to buy robots from you now, but you don't have what it takes!"

This point illustrates what I was discussing in a previous post : that current robots are not yet suitable for a very high number of potential end users. While I had mentionned this fact for SMEs previously, Lewandowski's presentation made me realize that this is also the case for massive non-automotive companies like P&G. And, this category represents an important market, considering that the robot density in packaging (Number of robots / employees) is less than 10% of what it is in the automotive sector (Source: World Robotics 2010).

Here are the specs of the ideal robot from P&G's point of view:

- Smaller footprint and larger workspace

- Lower integration cost

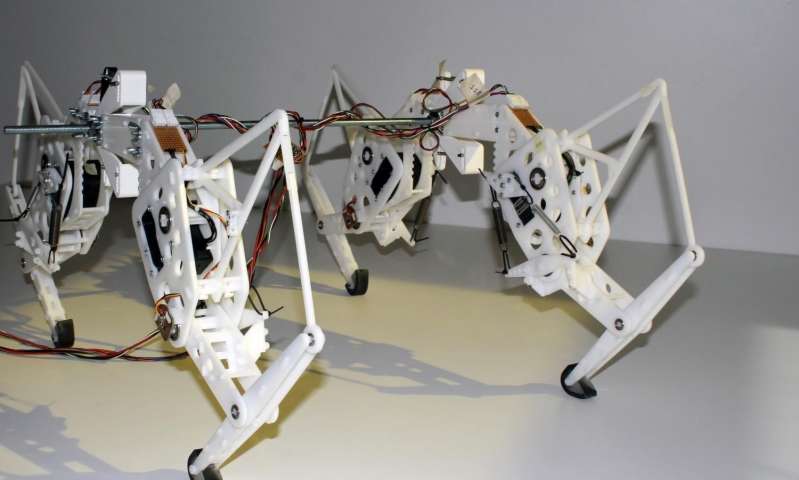

- Use a modular "lego" approach to build systems out of standard building blocks.

- Simplify the setup with basic functions already built-in

- Have robots easily talk to other automation components such as PLCs.

- Lower buying cost He said that a 50% lower cost could justify the ROI for a lot of applications.

- Collaborative They spend a lot of money on guards to protect humans from robots. This also uses space where no value-adding process can be done. They'd like robots that are aware of their environment and the humans that surround them.

When I asked what features from traditional robots could be left aside, the only aspect he mentioned was their ruggedness. He stated, "You don't need massive casted parts in packaging." Still, he added, he would not want to compromise on speed, relability or precision.

Leave a comment