Are Collaborative Robots Safe?

Posted on Feb 23, 2016 7:00 AM. 4 min read time

With a constantly growing market, collaborative robots are being used in all types of applications without any fencing. After all, this is what they have been designed for, right? Well, yes! But, does this mean that force limited collaborative robots are the epitome of safe? Can I get crushed by my UR3? Can a Baxter stab me with a sharp part? Can an IIWA still punch me? Let's find out!

Why does safety suddenly matter in robotics?

Actually safety has always been a concern. A robot is a machine and machine safety has always been a concern. The fact that robot use is safer nowadays is due to the work that has been done specifically on robot safety and the different regulations that have been instituted to make sure they are safe. However, the fact that robots are now working alongside humans increases the probabilities that humans can get hurt. This is why robotic safety is now a bigger concern. You also need to know that a very specific kind of cobot is designated in terms of safety; force limited robots. These types of robots are generally misnamed collaborative robots, but they are the only type of robot that can work alongside humans without fencing or other safety devices. Other types of robots can be collaborative, but they require additional safety devices to make sure they are 'collaborative'.

What makes them safe?

Force limited robots are sensing their environment, so they can feel impact or a wrong trajectory and immediately stop. All of this is possible because of the additional sensors embedded in them, usually at the joints or base of the robot or both. In fact, their motors are current monitored and a peak in current (impact) will stop the robot.

This explains why a cobot can revert to emergency mode when a high acceleration is asked of the robot. A fast acceleration will create a high current peak and depending on the robot settings this might generate a 'false' impact signal, which would trigger the robot default, usually an emergency stop.

Making sure the robot can always feel an impact and how fast can it feel it? Well, that is probably the nightmare of all collaborative robot manufacturers. They have to make sure that the robot motors always have redundant encoder systems so if the first one fails, the second one will be a backup. They also use certified encoders (or other positioning methods) that allow them to be precise and make sure the system does not fail.

There is an entire world of safety lexicon and expressions, but in robotics, the ISO 13849-1 standard is generally used to rate the safety level of a robot. The nomenclature used is generally, does it meet the PL d Category 3 standard for machine safety.

This basically means that the safety devices used in the robot (generally encoders) have a Performance Level: d and are rated as Category 3 in terms of redundancy (used in parallel). To learn more about this subject, check out this eBook.

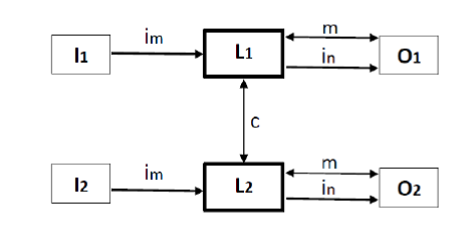

Category 3-4 redundancy level

All cobots answer to at least PL d, Category 3 requirements, but some may have greater safety ratings by the way they are built. All of this is designed to make sure that the robot doesn’t fail in case an encoder or a motor fails during the running of the robot. You wouldn't want to be next to a robot that doesn’t know where it is.

Inherently safe

With the recent ISO/TS 15066 a lot of data has been accumulated on the level of pain that a human can tolerate given certain specifications. Using this data a couple of charts have been put together on how much pressure and force (both static and dynamic) a human can endure before feeling pain. That being said, to design a robot that would respect all of the force/pressure requirement would be pretty damn hard. In fact, as dynamic force is directly related to speed and pressure is directly related to force and pressure area, to meet these requirements you would have to build a robot that is pretty bulky and slow... Well, that's pretty much a collaborative robot, right?

In fact, most collaborative robots (if not all) have round shapes, no dangerous openings and pretty limited speeds. However, does this make them inherently SAFE! Not quite sure. In fact, to be able to always respect the lowest force required not to hurt a human is pretty much impossible. Well you do want your robot to be able to do something, right! And this is the tradeoff, enough speed and pressure to accomplish the task against safety in the case of human contact. This is why the technical specification was released. In fact, without any guideline, how could robot manufacturers develop robots that could respect these force guidelines and accomplish anything.. well, that's pretty hard.

Importance of risk assessment

So for the moment since there aren’t any inherently safe robots, the best way to raise your safety bar and to reduce the risk of accident is to do a risk assessment. The new specs also include a risk assessment process that is specific to collaborative robot applications. You need to remember that even if a robot is 'safe' and its end effector is 'safe', the application and its environment still have to be considered in the risk assessment.

So to answer the starting question; Are collaborative robots safe? I would say Yes* (with a big asterisk). Collaborative robots can be safe under the condition that all potential risks are reduced and that the cell is running within these requirements from the moment the truck drops the pallet on the shop workfloor to the end of the robot lifetime. If you are going to install a collaborative robot on your shop floor, make sure to read our eBook on risk assessment and to read the relevant standards that cover robot safety for your application.

Leave a comment