Math's 2015 recap

Posted on Dec 16, 2015 7:00 AM. 6 min read time

Wow! 2015 just flew by! I was looking back at what happen over the past year in the robotic world and a lot of stuff happened. Writing several blog post per week, I was able to stay close to the robotic world. From tragedy to fist pumping, here's my recap of the year.

The father of robotic left at age 90

It is always sad to lose a member of our robotics community. The father of robotics, Joseph F. Engelberger died at age 90, December 1st 2015 at home. The “father of robotics” was the nickname given to him, because he designed the first industrial robot. This robot was first installed at a General Motor’s plant in 1961. The plant was later bought by Westinghouse. But what is most interesting in this story is that Mr. Engelberger was the starting point for the development of the robotic market. He introduced life changing technology that has enabled industry to introduce machinery capable of handling dangerous and repetitive tasks, while keeping humans doing human sized tasks. To have the complete story, take a look at the article on the RIA website.

To get a perspective on the history of robots, take a look here.

Volkswagen Accident

I'm not talking about the huge TDI environmental incident, but the fatal accident that happen earlier this year in one of Volkswagen’s German plants. Though such news is never fun to hear, it is still a marking event of 2015. Since this incident, I have been invaded by safety concerns from people that are afraid that robots are dangerous and that they could kill people. And it is events like this (though luckily they are very rare) that remind us, that we are working with dangerous, fast, strong and at the moment unintelligent machines.

This is why a safe environment has to be establish and a sensitization has to be insured to prevent other fatal accidents in the future. To make robot safety statistics talk, I suggest you read the following article. If you are concerned about collaborative robot safety, take a look at our eBook on risk assessment, it will direct you towards what is necessary to insure a safe application.

Was 2015 really the year of the mobile manipulator?

I predicted that 2015 would be the year of the mobile manipulator (remember this article?). And I think I was partially right! Well, mobile manipulators did not explode as I expected, but there were still a lot a new releases for new mobile platforms throughout the year. Most recently Clearpath Robotics has release a mobile platform to automate warehousing.

So even if the technology has a big potential, it seems like the market is a little slow in adapting these robots. The hype around it will probably come later. The same thing happened with collaborative robots, it took a couple of years for the information on them to be disseminated, so that people were aware of what they were good at and how they could be incorporated into specific operations. So I think it is just a question of time before these kinds of platforms take a big chunk of the market, and hopefully we will be able to supply a couple of Grippers on some of these manipulators, because for some of them this would be a perfect match.

Collaborative robots, hell yeah!

Collaborative robots though, were in the spotlight in 2015. In fact, with ABB’s YuMi, Universal Robots’ UR3, Fanuc’s CR-35iA, Rethink Robotics’ Sawyer among many others, the collaborative robot model was the one to explode over the last year. The cool thing about all these new robots is that they all cover different parts of the market and there is very little overlapping in terms of functionality. Green Fanuc for large applications; YuMi for small electronic assembly; Sawyer for applications that require vision plus worker monitoring and finally UR3 for a wide range of applications that have a small payload (assembly, dispensing, etc.)

In other words, I think 2015 was actually more The Year of the Collaborative Robot than the year of the mobile platform. My bad! But hey, keep reading and see how well I do for next year!

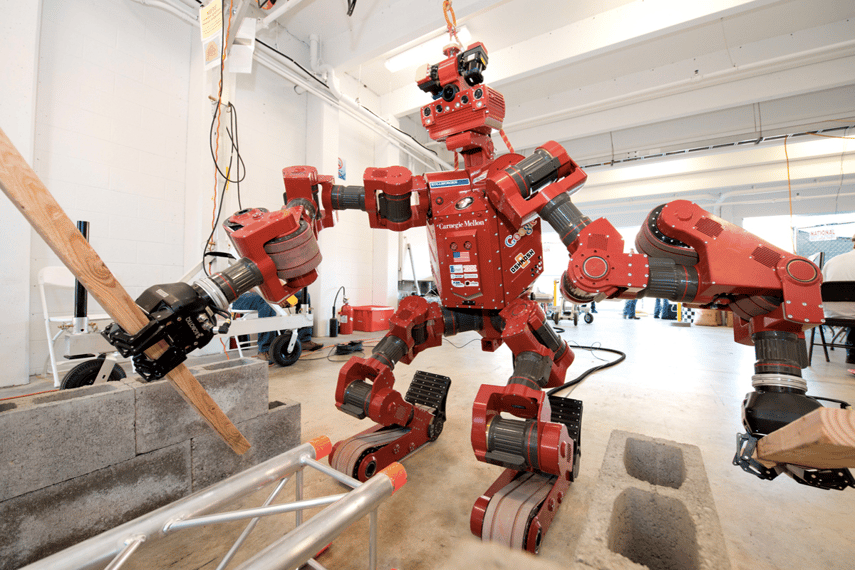

DRC: DARPA Robotic Challenge

The DARPA Robotics challenge came to an end last June with the grand finale. The event took place in Pomona, California where 25 teams competed for a prize money worth 2M USD. The competition was more challenging than ever, because of the updated requirements from Darpa. In fact, with no safety rope, communications degradations and a mystery challenge, the tension was pretty high.

The final result was determined by a question of seconds. A couple of teams would complete all the stages, but the fastest one would win the grand prize. The awards went to: Team Kaist (Korea), Team IHMC Robotics (Florida Institute for Human and Machine Cognition, USA) and third Tartan Rescue (Carnegie Mellon University, USA). With both IHMC and Tartan using our Robotiq 3-Finger Adaptive Gripper to complete the challenge.

To have an insider view of the DRC, read the following article.

What happened on our side?

On our side, we have been busy with a lot of events including: the DARPA Robotics Challenge, different shows and a couple of Webinars here and there. We are still looking to democratize the use of robots in SME's and transform robots and robotic tooling so that it is easy to use and that everyone can enjoy them.

We also launched 3 new products. The 2-Finger 85 Adaptive Gripper was released and well received by the market. We got a bunch of good comments on it and are still striving to enhance its grasping capability and ease of installation. We also launched a wider version of this Gripper, the 2-Finger 140 Adaptive Gripper. This Gripper is kind of the big brother to the 2-Finger 85. It has the same mechanical and electronic principles, but with a 140 mm stroke, this allows it to grasp a wider range of parts with a smaller payload.

Finally we also launched our FT-150 Force Torque Sensor. The sensor enables the robot to feel the force applied on the end effector. So, if you have an application that requires a sense of touch, this is the next tool to add to your robot. With a sensor like this you can, use the ‘teach by demonstration’ programming method. Also, the industrial robot can ‘feel’ what it is touching when assembling parts, for example. This means that you can increase your applications level of dexterity and logic when using this device.

What will happen in 2016?

Who knows, I am pretty bad at prediction as you may have noticed above. It may end up that my predictions will come out in June of next year and I will still be off the track. But in any case, the continually increasing collaborative robot market will be something to watch. I am also concerned about robots (or robot-copy) in China. It seems like they are increasing at a phenomenal rate and this can potentially affect major robot manufacturers, because of the volume they will looking for. In the meantime, we can only watch and hope they will create great quality robots that can compete with the American, European and Japanese robots.

Finally, on our side of the story, a lot of exciting projects are on their way and will be released soon, but of course I can’t tell you about them until they are ready for release! The team is getting bigger and the projects more exciting, we are all very excited to start 2016 and show you our new projects.

Have a great holiday! We will be slowing the blog pace down a bit over the next 2 weeks, so that everyone can enjoy the holidays. This will give me a chance to get out on my bike! I hope you enjoy your favorite activities, they might even have to do with robots!

Leave a comment