Lowercase's 5-Day Integration Project

Posted on May 31, 2017 7:00 AM. 2 min read time

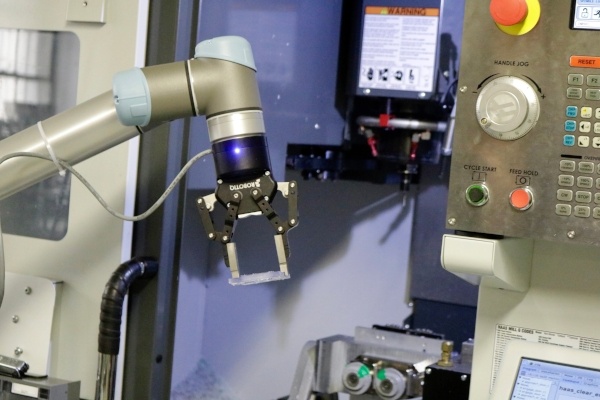

Two friends without any manufacturing background wanted to bring back eyewear production to the United States. They started their brand, Lowercase NYC, and automated their processes right from the beginning. In only five days, they’ve programmed a Universal Robot and Robotiq’s 2-Finger Gripper to operate the CNC machine by itself, allowing the three employees to focus on the countless things they have to do in this start-up business.

Since the 80’s, American eyewear manufacturers were all bought by foreign interests, stopping the domestic production in the process. Since then, most American eyewear brands sell products that are made overseas. Two years ago, an architect, Brian Vallario and his friend Gerard Masci, a finance worker, decided that the time has come to bring back something that was long gone in the American eyewear industry: the made in USA label.

Curious to see how they did that? Jump into the first of three videos from our latest case study!

“The main problem was that the integration cost of most robotic solutions was 3-4 times the cost of the solution itself.”

Since one of the co-founders came to the eyewear industry with a financial background, any equipment chosen to build the factory had to be worth every penny. Gerard Masci was willing to get started with collaborative robots, but he quickly realized that the price of a robot and the price of integration were two different things.

In the case study's part 2, see how collaborative robots made financial sense for this young startup.

Building-Up Today’s Manufacturing Startups

Eyewear production is a very labor-intensive process and for a small team like Lowercase NYC, any improvement that can be made on overall efficiency is huge. Having a product that operates by itself allows every employee to sit at the computer and work on design or go work on the more labor intensive stuff that can’t be done by machines, for example.

Without seeing life through a pair of pink glasses, Brian Vallario and Gerard Masci definitely see great things coming for Lowercase. Automation is an important part of many of their future projects, not only regarding the addition of new robots in the factory, but also to raise hires.

In the third part of this case study, see why collaborative robots integration was a perfect match for Lowercase NYC from the beginning, but also for years to come.

You can't be too small for cobots: It’s time for you to get started with your automation project today!

Leave a comment