Introducing a Collaborative Robot in a Global Company, What Does it Mean?

Posted on Jun 15, 2015 3:57 PM. 5 min read time

Gather your Information Together

Use whatever information management platform is already existent in your company. Put this content there. Follow up with key people to make sure they read it. Get their feedback, enhance the FAQ.-

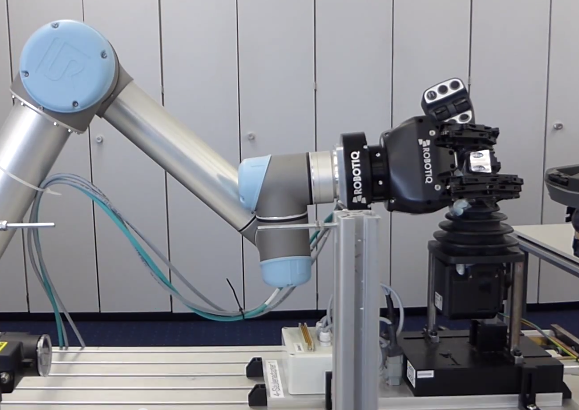

What is a collaborative robot ? Even if you have a good idea of what collaborative robots are all about, you may want to develop the details a little more. Stuff like safety features, vision systems, force-torque sensors sensibility and other things can be really useful when it's time to identify a specific application or simply to get data on the robot. To see the different collaborative robot models and specifications, we have put together a document regrouping the most poplular models all in one place.

-

Success stories : You are (probably) not the first one to automate a given application with a collaborative robot. Look for case studies of other companies or robot manufacturers and get ideas here and there to build your final solution. Trust me I have spent a lot of time on youtube to get a general idea of what was going on in the industry, you may want to start there.

-

Collaborative robot FAQs :

-

Suppliers : Depending on your region/country you will have different suppliers for robots, grippers, vision systems and other devices.

-

Specifications : Look at the payload, speed, repeatability, IP rating and safety features of the robot to have a comprehesive idea of it. This will guide you in your top choices. Remember to establish your needs before exploring the different robots or you may end up with stuff you don't need.

-

Pricing : This will also depend on your region and supplier. Some robot manufacturers/distributors will have price variations depending on the region you are in. Just make sure you are doing it right.

-

Safety and standards: Integrating a collaborative robot often means that you will not need fencing. However, it is not because the robot is safe that the application is safe. Make sure to consider all the different aspects of your robotic cell before stamping it as safe.

-

What it can/can't do : I have heard several times of people talking about what they want to do with a robot, and sometime the technology is just not their yet. Make sure to have applications that can be done with your collaborative robot. Remember to keep it simple. You can also expose its functionality to your workers so they can have a better idea of what it is meant for and maybe have new ideas for future applications.

- Company specific risk assessment template : As you may be familiar with the risk assessment process, you should use the same template and method you have used in the past. Collaborative robots are machines just like all the other ones in your plant, so you have to do a risk assessment. Remember that it's not because the robot is safe that the application is safe. You should also consider the possibility of exporting the cell to other plants, but remember the cell must still be approved there although perhaps with only minor changes.

Get Management and Workers Onboard

Your employees are your most valuable resource. Adding a robot to the loop can sometimes appear threatening or strange for your workers. Some will totally refuse the introduction of the robot and some will accept it as a new challenge. You'll have to figure out the best way to introduce a robot without adding extra worry for your workers.

The worst thing you could do is to put a robot on the floor before communicating with your team! In many instances deployment is push back because of unclear communications . Doing it right means waiting until most everyone is cool with the fact that the robot is good for them and for the company. Most integration fails comes from a lack of information to some layer of the enterprise. Remember that the Universe hates void. If there is an information void, it will be filled with all sorts of questionable information. “Is it here to steal my job?”, “A robot without a fence, it’s dangerous!”.

If the people on the shopfloor want the robot not to work, it will not work. They need to be part of the process for success and then there will be success. Show them in and environment where it’s safe to learn (individualized training, no one watching their mistakes, someone to answer questions) that it’s simple, that they can learn and that it’s fun. And after all it is a collaborative robot that is meant to work alongside humans. It definitely must be accepted within the company for it to work. You could also identify who are the most important skeptics capable of imposing their ideas. You’ll need to convert them with hands on experience working with the robot.

To begin the implementation of the robot on the workfloor you need to start training people with a certain skill set. They first have to be open-minded and ready to use new technologies. They also have to be good with ''computer'' stuff and be good communicators. With all these little tips, you can select people that will be able to learn at a fast rate and will be able to make it look easy. Then other employees will want to use the robot because it looks like fun!!! And it really is honestly.So, hopefully these few tips will help you with your integration. Getting your stuff together to have the right information before buying a bunch of stuff only to realize you don't really need it all and preparing your workers to work alongside a robot will make the integration a lot smoother. If you need information on how to integrate a collaborative robot in your company, you may want to take a look at the document in the link below.

Leave a comment