Getting Started with Collaborative Robots: Product Testing

Posted on Mar 23, 2016 7:00 AM. 5 min read time

You are looking at your first robot integration, you have heard about collaborative robots, but you don't know where to start? You’ve come to the right place. We have put together this blog post series to help you figure out which robot will match your specific application. For our third blog post, we'll talk about product testing applications. The first post on machine tending can be found here, and our second post on assembly applications is here.

What is product testing?

Whatever you are doing as a manufacturer, you most likely have product testing and/or quality checkpoints where your product is tested. If a step is skipped or a part is wrong, this step of the manufacturing process will trigger an error and will tell you that your product is defective. As some tests have a long run cycle and employees have more interesting things to do than pushing on 27 different buttons in a given order, robots can be introduced to perform this task.

What about product testing with a collaborative robot?

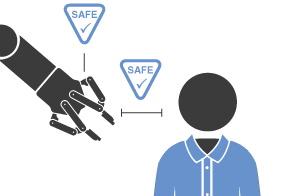

A collaborative robot or cobot for short, is a general term used to describe power and force limited robots. Robots that can be used without safety guarding or that incorporate other safety features. This means a cobot can be put beside a machine or a person and set to perform a certain task without needing to be fenced off from its surrounding environment.

That being said, to introduce a cobot on an assembly line or beside a test bench and program it to test parts is not as simple as it sounds. You will need to choose a robot that can accomplish the job and that can reach a level of performance comparable to a human worker. To help you, we have listed some key factors you might consider for product testing if you are using a collaborative robot.

Robot Specs

- Repeatability: The robot has to be consistent in its motions to test products with tight tolerances. In fact, with small/fragile parts such as a printed circuit board (PCB), you need to be highly repeatable in order to test the products and make sure not to damage anything as a result of the testing process. You will need to choose a robot than can meet your application’s demands in terms of repeatability.

Tip 1: If you need to repeat a given action an infinite number of times, make sure to buy a robot that can respect the position tolerance you need to achieve. - Speed: In some product testing applications, speed is very important. Granulated speed control can make a difference in your product testing, but it can also play a huge role in your cycle time.

Gripper Specs

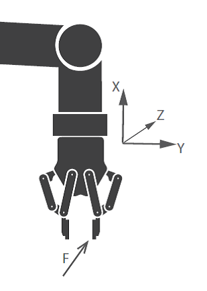

- Force Feedback: We see, daily, a lot of applications that require force feedback. Using a force torque sensor will allow you to have consistent force/pressure applied on a given region of the product for whatever you want to do. This means that you can limit the force at a given point and collect this information for your database.

Tip 1: Make sure the force torque sensor used can carry the payload of your heaviest part. - Flexibility: As seen in the video above, you may need to carry different kinds of objects, as well as open or close doors to achieve your product testing. This means that a flexible gripper is probably necessary.

Tip 1: Super flexible grippers (5 fingers for example) usually have a low payload and very high price point. Make sure you are using a gripper that meets your payload requirements and that is strong enough to perform your industrial application.

Tip 2: Go for an electric Gripper, they are easier to implement and reduce the integration time.

Required Workspace

- Safety: The robot will work alongside humans. Some will be aware of the dangers this presents, others won't. Make sure to perform a risk assessment before building your automation project. Once you're ready to go live, make sure everyone is trained on safety rules around the robot and the risks involved with using a robot. Collaborative robots are safe, but can still represent risks to the workers.

Tip 1: U se ISO standards to guide your risk assessment and don't forget to consult local regulations on this subject. To learn more, download this eBook on risk assessments for collaborative robots.

se ISO standards to guide your risk assessment and don't forget to consult local regulations on this subject. To learn more, download this eBook on risk assessments for collaborative robots.

Tip 2: Remember, even if the robot itself is safe, if the tool or the part it carries is dangerous, then the robot cell in and of itself poses risks for your workers. - Machine Interface: Make sure to interface your robot with the machine you will be using. Most of the time a programmable logic controller (PLC) or a simple PC will be used to perform the testing or collect data.

Tip 1: This seems simple, but this is probably the most complex part of the process. Make sure to reserve time and budget for this one.

There you have it, this is a basic overview of robot, gripper and workplace specifications that you might consider if you are thinking about implementing a cobot to do your product testing. If you need more information on how to shop for a collaborative robot or what key features of a cobot might be important according to your application, we have put together a complete eBook on this subject. Or you can contact one of our application engineers who would be happy to discuss your automation projects.

se ISO standards to guide your risk assessment and don't forget to consult local regulations on this subject. To learn more, download this

se ISO standards to guide your risk assessment and don't forget to consult local regulations on this subject. To learn more, download this

Leave a comment