Is 2013 the Year for Bin Picking in Robotics?

Posted on Mar 14, 2013 10:03 AM. 4 min read time

For the past two decades, robot manufacturers have been working hard to put in place efficient robotic bin picking systems. While the automation of many different production processes have been progressing quite fast, it was still necessary to put people in highly repetitive tasks: sorting parts to feed a robot or a machine. But now with the technical progress of 3D vision systems, computation and flexible end-effectors; the what we call “Robotics quest for the Holy Grail” seems to soon be a reality for today's industrial day-to-day production line.

For the past two decades, robot manufacturers have been working hard to put in place efficient robotic bin picking systems. While the automation of many different production processes have been progressing quite fast, it was still necessary to put people in highly repetitive tasks: sorting parts to feed a robot or a machine. But now with the technical progress of 3D vision systems, computation and flexible end-effectors; the what we call “Robotics quest for the Holy Grail” seems to soon be a reality for today's industrial day-to-day production line. The Bin Picking Challenge

I know, I know, you are perhaps a bit sceptical about this bin picking progress. We've heard so many times that it would soon be a reality that you are right to be doubtful. Bin picking represents a big challenge in automation due to the following factors:

- There are often so many geometry types on each part to consider for proper handling;

- Parts are in a random and unstructured environment;

- Vision systems have to be very precise;

- Computation behind the system has to be able to make sense of all the data detected by the vision system;

- The robot has to be equipped with effective and flexible end-effectors to be able to handle the parts in many different ways;

- You can expect many failures along the way, banging your tool on other parts and bin walls.

Factors Supporting Bin Picking Viability in the Field

Enhanced Vision Systems

The progress with vision systems have been impressive in the past decade. The Microsoft Kinect is a great example of that: a 3D camera system that can track human movement, replicate it and map the surrounding environment for only $150. This device has been very useful for many research centers allowing them to develop new applications including vision at low cost. See in the following video what Yaskawa Motoman did with one of their robots in a depalletising application.

Computation

This has been the major issue with bin picking: computation. Being able to calculate 1D linear segments, 2D features or 3D scenes was something feasible. But making sense of all this data was a significant challenge. Many excellent papers and books have been written on the bin picking issue. One book in particular that bridges theory and practice is Artificial Vision for Mobile Robots by Nicholas Ayache.

At past tradeshows, we've seen many interesting things concerning this; for example, here is one solution proposed by Industrial Perception Inc. In the following (and funny) video, we can see a vision system that can detect objects and do modeling of it; be aware of its environment; and plan a path and trajectory.

Flexible end-effectors

Having an end-effector that is able to handle parts in various positions also represents a challenge for this application. Vacuum cups, pneumatic grippers and electric grippers are solutions that can be considered to surpass this challenge. Each method has some positive and negative aspects.

Vacuum cups

Vacuum cups could be a solution, which would allow the robot to go directly to a part and pick it up, like in the following FANUC video.

For an application where parts have regular geometries and a lot of flat surface space, vacuum cups can be a solution. However, when parts are irregular things get more complicated. Often there are not enough flat spots on which the vacuum cups can have a powerful enough, safe grip.

Pneumatic grippers

Depending of the parts to be handled, pneumatic grippers could also be a solution. However, the lack of flexibility related to the gripper opening and closing could be an issue. Having to do partial closing to reach a part is hard with pneumatic grippers. This could eliminate handling possibilities.

Electric grippers and servo grippers

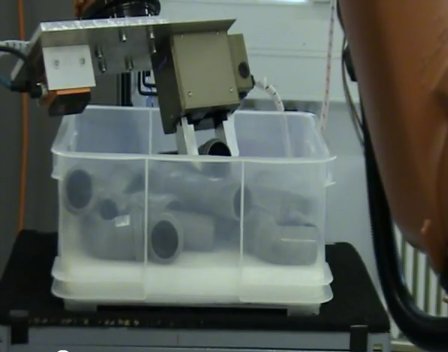

The development of electric grippers (servo grippers) offers more grasping possibilities. Being able to adjust the speed, force and position of the fingers adds grasping options to the robot. Moreover, flexible electric grippers can adjust to a wide range of part shapes and geometries without in-depth programming. Here is an example from one our our partners, Robomotive. In this demo the Motoman dual arm uses the 3-Finger Adaptive Robot Gripper to do bin picking and to assemble parts. It also uses its robot gripper to handle pneumatic tools to reach smaller parts.

So will 2013 be the year of bin picking in robotics? I don’t know but all the parts to the puzzle seem to be falling in the right place. What are your thoughts about this?

Leave a comment