Robots to automate small or medium sized manufacturing plant

Posted on Feb 15, 2012 9:25 PM. 2 min read time

Is automating your manufacturing plant becoming a necessity to staying in business, are you wondering how you can afford to automate? If your a small manufacturer and thinking about automating here is an example of how one company went about it. Alison Dunn wrote in the November 17, 2011 issue of Automation Magazine about how an Ontario company, Oakville Stamping & Bending (OS&B) managed to upgrade their manufacturing systems and keep all their valued employees.

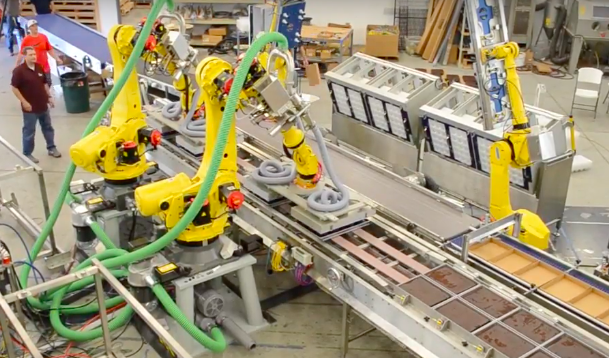

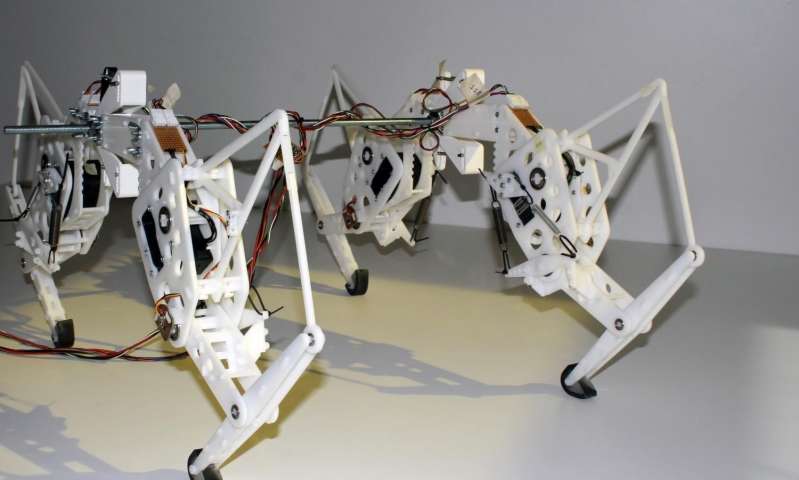

Cable-driven Delta Robot by AEMK at OS&B

OS & B is also a good example of how robotizing certain features of their assembly production both modernized their plant and gave them greater flexibility for future production options. While there were no new jobs immediately created in Oakville, no jobs were lost either.

The Oakville plant is typical in that it was seeing it's company squeezed out of the market by stricter health and safety regulations and old equipment which needed renovation in order to remain competitive.

When considering refurbishing, government subsidy programs and tax incentives are generally key for most companies to be able to proceed with these much needed improvements. In the Oakville, OS & B overhaul specifically, the Canadian Manufacturers and Exporters' SMART Program, plus private investment were the key resources relied upon. Each province has their own development, grant or loan programs and tax incentives, also local municipalities may also offer tax incentives. Basically this is the part of refurbishing which is very specific to your individual situation and location and there is nothing to replace the hands on grunt work of searching out the local programs which might apply to your specific case.

What is interesting about the OS & B makeover is the way the robot increased productivity and revitalized the production process, all while meeting today's increased safety regulations. When a robot is no longer a customized machine just doing one and only one task, this means that if in the future different applications are needed, the robot is generally flexible enough to handle it. Another interesting aspect of this story is the unique cable-driven delta robot from AEMK that was used. You can (barely) see it in the picture above or watch the video here.

Leave a comment