Automate 2017: Stäubli launches new cobot line

Posted on Apr 04, 2017 12:08 PM. 3 min read time

Mechatronics solutions provider Stäubli launched its TX2 line of cobots in the North American market this morning at Automate 2017. We were there!

.jpg?width=640&name=Image%20uploaded%20from%20iOS%20(12).jpg) Caption: Stäubli North America’s Robotics Division Manager Sebastien Schmitt speaking at this morning's press conference.

Caption: Stäubli North America’s Robotics Division Manager Sebastien Schmitt speaking at this morning's press conference.

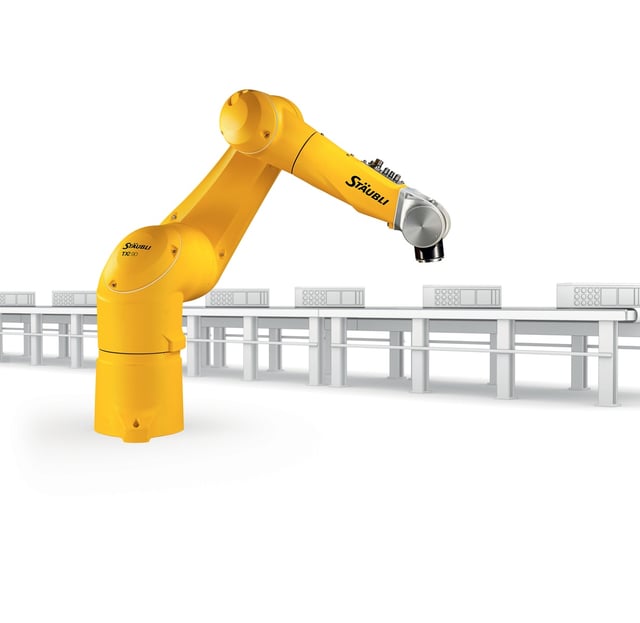

The new TX2 line from Swiss robotics firm Stäubli is a six model series --TX2-40, TX2-60, TX2-60L, TX2-90, TX2-90L and TX2–90XL-- that's capable of handling loads between two and up to 15 kilos with a reach between 515 and 1,450 millimeters.

Caption: The TX2 40

Caption: The TX2 40

The TX2 line are six-axis machines designed for use in high-volume manufacturing, Industry 4.0 applications, and human-robot collaboration scenarios.

“Because of their incredible versatility, the new line is redefining performance by allowing manufacturers to adjust to changing production needs,” said Sebastien Schmitt, Robotics Division Manager, Stäubli North America. “The TX2’s pioneering safety features and clean, consistent performance improve productivity in every facet of manufacturing.”

Schmitt explained that the line is aimed at two main types of company: those that already have industrial robots and want to move to cobots and companies that have "standard" cobots and are seeking improved performance.

Billed as "the world's fastest safe robots," the TX2 line offers five stages of "man robot collaboration":

- Stage 1: Hard guarding separates the operator and robot. The manufacturing

process is performed by the robot.

- Stage 2: Laser (virtual) guarding separates the operator and robot. The

manufacturing process is performed by the robot, and the operator enters the area

periodically.

- Stage 3: Laser (virtual) guarding separates the operator and robot. The robot and

operator are involved in the manufacturing process. The operator enters the zone

regularly during production.

- Stage 4: There is no separation between the robot and operator. The robot and

operator are involved in the manufacturing process. The robot stops when it comes

into contact with the operator.

- Stage 5: There is no separation between the robot and operator. The robot and

operator are involved in the manufacturing process. The robot and the operator

move safely in the same space simultaneously.

Caption: The TX2_90

Caption: The TX2_90

“Bringing the world’s fastest safe robots to the North American market shines a spotlight on our incredible commitment to innovation,” said Roger Varin, CEO, Stäubli North America. “The new TX2 line is reshaping manufacturing by allowing humans and robots to safely co-exist while improving productivity.”

Stäubli opted to use standard models for man-robot collaboration and has "dispensed with the construction of typical assistant robots, which limit performance."

“Such robots are generally subject to excessive restrictions on load and dynamics, which is why we have adapted our standard robots to work with people without compromising on performance,” says Schmitt. “With the TX2 six-axis robots, we can facilitate different levels of MRC. At the same time, the outstanding performance of these machines in terms of precision, reliability and speed means that they remain the first choice for all conceivable industrial applications that are subject to the most exacting cycle time criteria, which constitute the majority of applications in industrial practice.”

The TX2 line is set for launch in 2018.

How does the TX2 line stack up against its competitors?

Well, it's early days, of course, but the specs are certainly impressive. Our initial impression was that Stäubli, like other robotics firms, has collaboratized their existing robots by adding additional sensors and safety features --an exciting development and one that demonstrates the growing global appeal of cobot technology.

Leave a comment