Parallel Robot Grippers: Which is Best?

Posted on Jul 03, 2018 7:00 AM. 7 min read time

There are so many options for grippers! Which one is best? We compare two types of grippers head-to-head.

Parallel grippers, adaptive grippers, big grippers, small grippers… there are a lot of different terms for robot grippers out there!

But, the real question is… Which is best?

In this article, we compare the advantages and disadvantages of the two gripper types, and compare them head-to-head… in a showdown.

Each new gripper makes selection a little bit harder

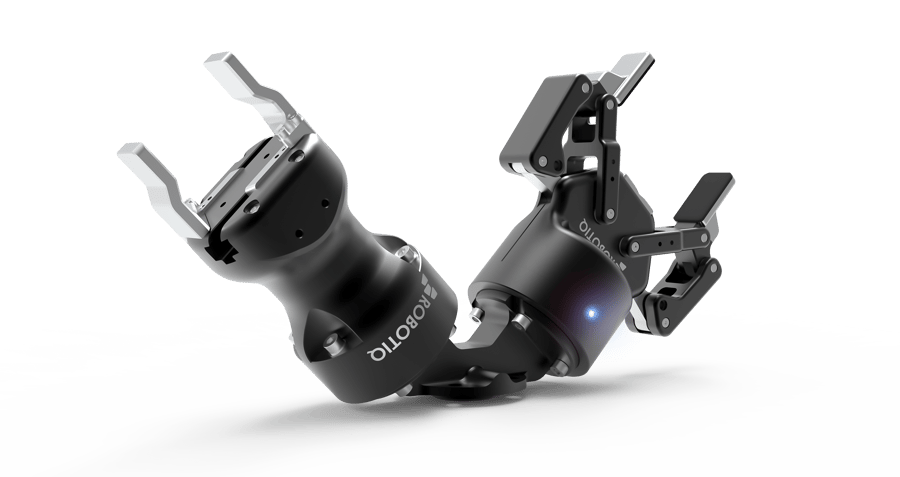

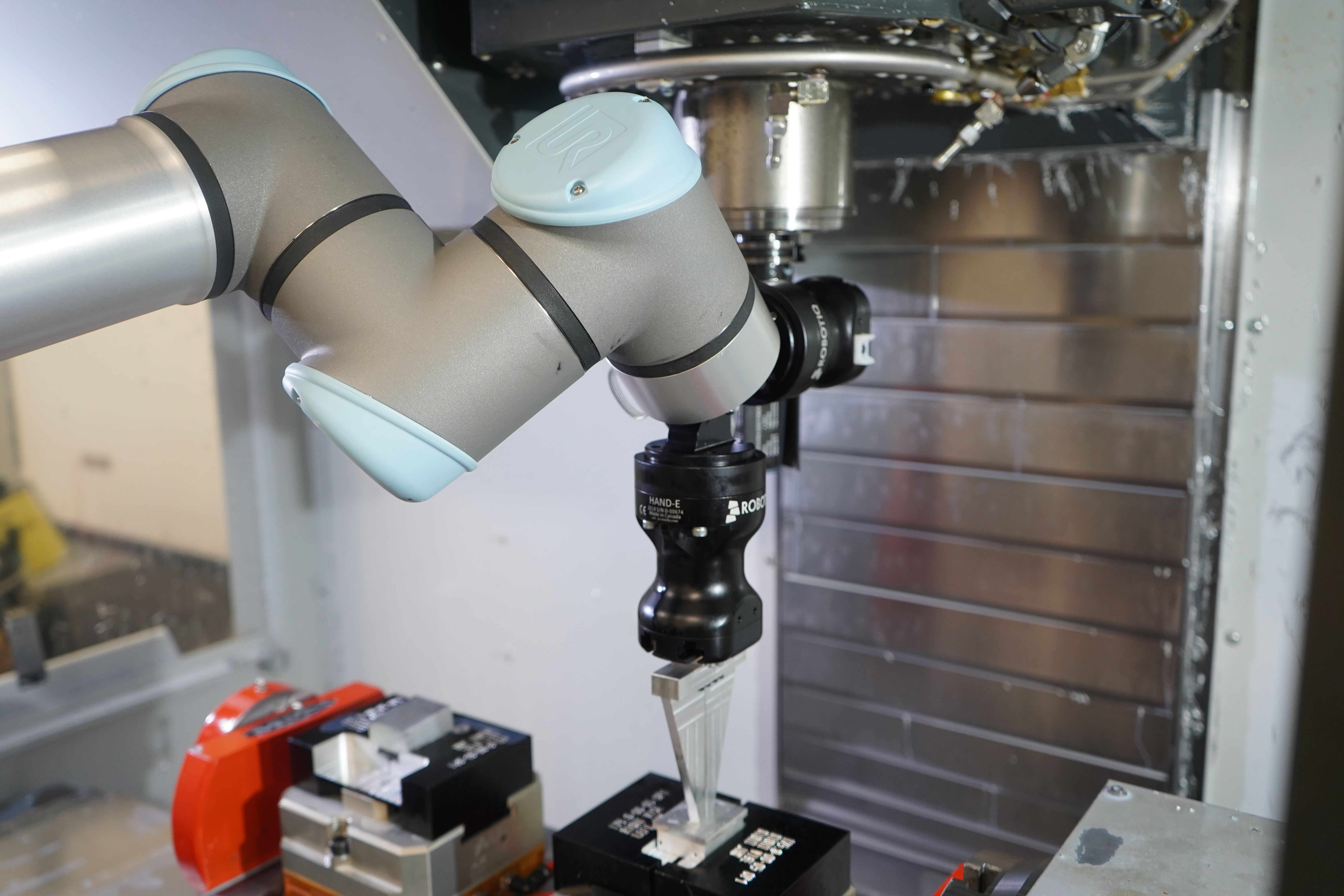

Hand-E is our first translational gripper. It's got many of the advantages of our popular 2-Finger Adaptive Grippers — which we've been building for 10 years — but with the added bonus of being a highly customizable parallel gripper suited to precision applications.

We understand if you're a bit apprehensive about this new gripper. After all, it makes the decision of which gripper to buy just that little bit harder. You may be wondering: What are the advantages of a translational gripper over a rotational one? Is this gripper more flexible? Which is the best for my application?

Relax. Don't worry. Let's clarify the differences between the two types.

What is a rotational gripper?

All of our adaptive grippers allow a robot to pick up a wide variety of different objects without ever needing to change the gripper. However, our rotational grippers (2F-85 and 2F-140) have the capability to adapt to the shape of objects, allowing a secure grip without the need for custom fingertips.

The flexibility of the fingers comes from their parallel linkage mechanism. This cool (and patented) mechanical design allows the fingertips to remain parallel as they grasp together and allows them to curl around objects for an encompassing grip.

Our 2-Finger and 3-Finger Adaptive Grippers have been game-changers in the collaborative robot market — if we can say so ourselves! As their flexibility comes from stiff, parallel linkages, they have a higher gripping force compared to some other adaptive grippers on the market which use flexible materials to adapt their shape around objects.

What is a translational gripper?

Translational parallel grippers allow the robot to perform precision grasps on objects within a narrow range of sizes. They tend to have a small stroke (the distance between the gripper being fully open and closed) — most parallel grippers on the market have a stroke of less than 50 mm.

The fingertips of a parallel gripper remain exactly parallel throughout their entire motion. This is different from the rotational grippers which follow a slightly curved path as they close. This is one reason that translational grippers are so good for high-precision tasks. Another reason is that Hand-E is manufactured to a very low tolerance, which contributes to its better accuracy.

One of the big advantages of such grippers is that you can easily replace the fingertips. This allows you to redesign them to perfectly suit your application needs. However, this can also be a disadvantage if it restricts their adaptability to different tasks. In the past, many translational grippers on the market came supplied with no fingertips, only an actuation block. We avoided this problem by supplying Hand-E with a pair of multi-purpose fingertips which are well-suited to many common applications.

The vast majority of translational parallel grippers on the market are pneumatically actuated. Although there were benefits to pneumatics in the past, modern electric grippers are now reaching the same levels of performance without the disadvantages of pneumatics.Hand-E is a high-performance electric gripper.

Rotational vs translational grippers: the showdown

It's time for a showdown! Let's compare the two gripper types to see how they stack up against each other.

Here are the properties we'll be using:

- Stroke width: This is the distance between the gripper's fully open and closed positions. Note that this doesn't have to limit the maximum width of the objects as adding custom fingertips to any adaptive gripper allows you handle wider parts.

- Clearance: This is the space needed for the gripper to enter the workspace. You can visualize it as the minimum diameter of a tube that the gripper could fit through.

- Precision: This is the exactness with which the gripper can manipulate objects. All Robotiq grippers also come with inbuilt part detection — which allows you to detect when an object has been grasped — so this property also refers to the precision of part detection.

- Maximum Grip Force: The maximum force which the gripper can apply on a workpiece. Note that longer custom fingertips will reduce this maximum force, so you should recalculate this for any customizations you make.

- Environmental Conditions: The presence of dust and/or liquid in an environment is an important consideration for some applications. Some grippers have more protection from these than others.

- Customizability: All Robotiq grippers have the option to customize them with your own fingertips. But, Hand-E is especially well suited to customization.

- Hand Guiding: One of the major benefits of collaborative robots is that you can program them by physically moving them around. Some grippers are easier to hold onto than others, which facilitates hand-guiding.

Let's look at the differences in numbers:

|

Rotational Gripper |

Translational Gripper |

|

|

Available Models |

2F-85 and 2F-140 |

Hand-E |

|

Stroke Width |

85 — 140 mm |

50 mm |

|

Clearance |

148 — 202 mm |

75 mm |

|

Precision resolution |

0.4 mm |

0.2 mm |

|

Closing speed (adjustable) |

20 to 150 mm/s |

20 to 150 mm/s |

|

Maximum Grip Force |

125 — 235 N |

185 N |

|

Environmental Conditions |

Some dust or drops of liquid |

Lots of dust or splashes of liquid |

|

Customizability |

Easy to add custom fingertips |

Easy to add custom fingertips |

It's clear that both types of gripper have different strengths. The rotational grippers have a wide stroke with high grip force, but they require a lot of clearance and are not as precise. The translational gripper has a small clearance, sub-mm precision and good environmental protection, but its grip force is not as high. Neither option seems better than the other in all categories.

Which is best for your application?

When considering a gripper, the question should never be "Which is Best?" Instead, the question should be "Which is best for my application?"

First, you need to be sure you are clear on the needs of your application.

Then, ask yourself the following questions to help decide which gripper type is best for you:

- What is the widest object the robot will pick up?

- What is the stroke that the robot will need?

- Is clearance an issue?

- How precise does the gripper need to be?

- What is the smallest dimension that the robot should be able to detect?

- How much force should the robot be able to apply on objects?

- How much dust or liquid will be in the environment?

- Will custom fingertips be needed for the task?

- Would easy hand guiding be beneficial?

If you still have some questions regarding which gripper is best for you, reach out to a member of our team, post a question in the comments, or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

Leave a comment