Why Vacuum Grippers Are Really the Best Option for Robot Palletizing

Posted on Sep 12, 2019 in Robot Grippers

6 min read time

Vacuum grippers are a very popular end effector for robot palletizing. What makes them such a good option and how do they compare to the alternatives?

Vacuum grippers are one of the most popular end effectors for palletizing robots.

Vacuum grippers are one of the most popular end effectors for palletizing robots.

If you were to search for images of palletizing robots, you would see a lot of photos of vacuum grippers. They are one of the most popular end effectors for palletizing robots, and with good reason! Vacuums grippers are very well suited to the needs of most palletizing tasks.

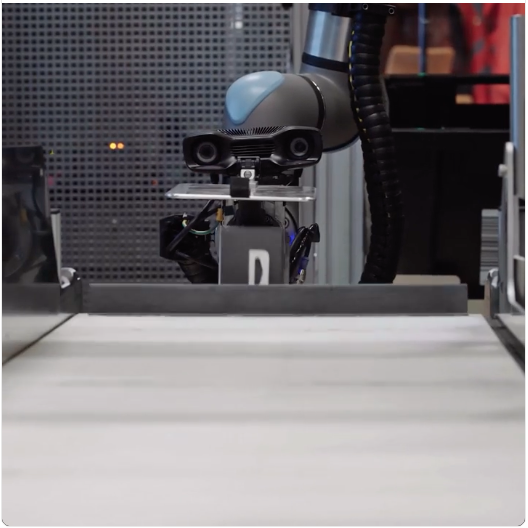

Collaborative robots are just as capable of palletizing as the more traditional industrial robots. With customizable vacuum grippers, cobots are the perfect option for lightweight packing tasks.

Why are vacuum grippers so well suited to palletizing?

What other gripper options are there?

How can you get started?

Let's find out!

5 requirements of a palletizing gripper

Packing is one of the most well-established tasks for automation. Palletizing often involves heavy payloads, customized pallet layouts, and long working hours — perfect for a robot!

Palletizing also has rather specific needs when it comes to your robot end effector. Here are 5 of them:

1. Parallel Load

Most palletizing tasks require that the objects are lifted from above — in other words, the lifting force is parallel and opposite to the force of gravity. In fact, there are a whole class of industrial "palletizing robots" which achieve this by always keeping their end effector parallel with the floor.

2. Distributed payload

Many robot tasks only require objects to be grasped by a single point. With palletizing, however, it is more common that objects are supported across their whole surface. This avoids twisting and deformation of the objects, and ensures that they are packaged in exactly the right orientation.

3. Customizable

Every palletizing task is as different as the range of objects which can be packaged. As a result, it is often necessary to customize the gripper so that it perfectly suits the needs of the task. Robots are often required to change between programs to allow for palletizing of different product lines.

4. Throughput

Palletizing is a high demand task and robots are often worked continuously. This makes sense because every product which leaves the business needs to be packaged. Anything which can increase the throughput of the packaging process could also increase the throughput of the whole business.

5. Gentle handling

When we think of palletizing robots, we often think of giant robot arms stacking trays of heavy boxes. However, many palletizing tasks require a more gentle approach. Gentle handing is particularly important with collaborative robots as they are more likely to be used to pack smaller, fragile objects.

Vacuum Grippers are the best option for robot palletizing.

Vacuum Grippers are the best option for robot palletizing.

Why vacuum grippers are the best option for robot palletizing

When you look at the properties of vacuum grippers, it's clear why they are so well suited to palletizing tasks. Their features match the requirements almost exactly! The great benefit of this is it means you don't have to fiddle around to get the gripper to work with your task — everything should just work easily out of the box.

1. Orientation

Vacuum grippers can work in any orientation. However, they are most effective when the lifting force is directly opposite to the force of gravity. This is perfect for palletizing because it means that you are using the gripper at its most optimal.

2. Distributed payload

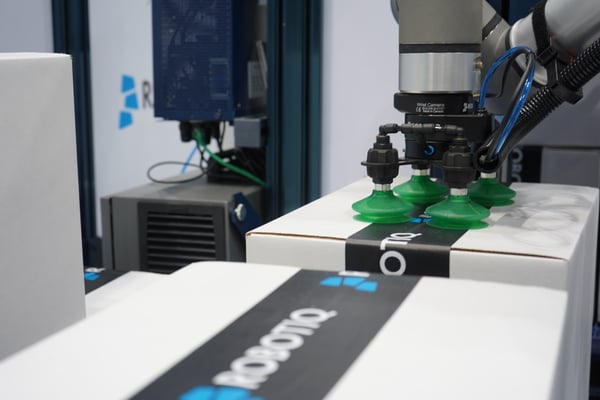

Although vacuum grippers can be used with a single suction cup, it is more common for them to include multiple suction cups arranged in a regular pattern. This allows them to distribute the payload over the entire surface of the object, which is exactly what you need for palletizing.

3. Customizable

The arrangement of suction cups is entirely up to you. For example, our EPick and AirPick grippers come with a few default configurations but you can customize these very easily to exactly suit the layout of the objects that you need to palletize.

4. Fast response

Vacuum grippers tend to have faster response times than comparable fingered grippers. This is because you don't need to wait for the gripper fingers to close to pick up the object. This speedy response time will reduce the cycle time, which ultimately improves the throughput of the entire robot cell.

5. Gentle handling

There is a reason why vacuum grippers are so common in the food industry — they are extremely gentle. Suction cups can easily handle any delicate and fragile objects, e.g. cookies, electronic chips, or glass. As this one of the key requirements for palletizing tasks, it makes vacuum grippers the perfect option.

Other options and how they stack up

Of course, vacuum grippers aren't the only robot end effectors which are suitable for palletizing tasks.

Here are a few other common options:

- Fingered grippers — You can do most things with a fingered gripper. However, the main problem for palletizing tasks is that you can only lift one object at a time, which significantly slows down the task. A dual gripper can help but the throughput can still be quite low.

- Clawed grippers — A common gripper for large industrial palletizing is the claw gripper (e.g. this one from ABB). It allows the robot to support the weight of heavy, deformable objects with very porous surfaces (e.g. bags of grain). However, it's not so useful for small palletizing tasks with light objects.

- Magnetic grippers — Magnetic grippers share some of the same benefits of vacuum grippers (e.g. they only require one surface and have a fast response time). However, a major disadvantage is that they can only be used with ferromagnetic materials.

- Custom grippers — A lot of palletizing tasks use heavily customized or custom-built grippers which are designed for the specific application. Although this means that the gripper perfectly suits the task, it can be costly and time-consuming, and they can be hard to alter when the needs of the task change.

How to get started with vacuum gripper palletizing

Palletizing is really the perfect task for vacuum grippers. To get started yourself, it can be helpful to learn a bit more about vacuum grippers and how they work.

For more information, check out our previous articles:

- The Simple Guide to Picking the Right Robot Vacuum Gripper

- 5 Doubts You Should Clarify About Vacuum Grippers

- Why a Vacuum Gripper Can Improve Your Packing Tasks

How do you currently palletize your products? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

.jpg)

Leave a comment