The Simple Guide to Picking the Right Robot Vacuum Gripper

Posted on May 23, 2019 in Robot Grippers

6 min read time

Choosing a vacuum gripper can be tricky. There are a ton of vacuum grippers on the market and picking the right one involves many different decisions. Here's the simple guide to picking the right one for your robot applications in just 5 steps.

Which end effector do I need for my robot?

Which type of gripper is best?

Which model?

The choice of end effector is one of the most vital (and difficult) decisions that you will have to make when designing your robot cell. There are a huge variety of different end effectors. Even if you know for sure that you need a vacuum gripper, there are still an astounding array of models to choose from.

But, don't panic. Picking the right vacuum gripper for your robot doesn't have to be hard.

Just follow these five simple steps and you'll have the perfect vacuum gripper in no time.

1. Clarify your application

The first step to buying your vacuum is exactly the same step that we recommend for everyone who is considering any robotic solution…

First, clarify your application.

In our enthusiasm to implement our solutions, we often forget this vital step.

Clarifying your application involves taking a step back. It involves asking "What are we trying to achieve with this cell?"

Do we need to increase throughput? Free up a human worker for another task? Improve task consistency? What are the key performance indicators that we are looking to improve?

Life becomes a whole lot easier when we are clear about what we are actually trying to achieve with a robot cell.

Not sure how to start? We have a whole eBook which describes this process — Getting Started With Collaborative Robots: Part I

Tip: Simplify, Simplify, Simplify

Simple ideas are much easier to implement successfully. There are usually several ways that you could further simplify your application before you start choosing gripper models. Check out How to Simplify a Complex Task for tips on how to simplify your application even further.

2. Ask yourself: Why do I need a vacuum?

Although vacuum grippers are popular, they aren't the only option. You should first consider why you need a vacuum gripper — if you do need one.

Tasks which benefit from vacuum grippers include:

- High-speed pick-and-place — When configured correctly, vacuum grippers can allow for very short cycle times. If you've ever seen an ultra-high-speed picking application, it almost certainly used vacuum grippers.

- Delicate handling — The only part of the gripper that touches the manipulated objects is its suction cup. Hardly any force is applied to the surface of the objects. This makes vacuum grippers great for handling delicate objects, like food or electronics.

- Wide, flat objects — Fingered robot grippers can lift just about any object… as long as part of the object can fit firmly between the gripper's fingertips. This makes wide, flat objects (e.g. a pane of glass, sheet metal) almost impossible to lift easily with a fingered gripper. Vacuum grippers connect with the object surface, so are perfect for this type of object.

- Hygienic handling — One of the reasons that vacuum grippers are so common in food and medicine manufacturing is that they are easy to keep clean. Suction cups are easy to sanitize and replace, which keeps the whole application hygienic.

However, there are many applications where a vacuum gripper just isn't necessary. For these, an adaptive gripper is often a better solution.

3. Identify your suction cup properties

The suction cup is the "business end" of the vacuum gripper. It will contact with the surface of the object and stick to it by applying the vacuum.

Choices you will have to make about your suction cup include:

- What shape of suction cup will I need? The shape of the object's surface and material type will affect the cup shape that you need.

- What type of suction cup? The common types are flat cups and bellows cups.

- If using a bellows cup, what stroke will you need? Longer stroke lengths apply more damping which makes them more gentle.

- How many suction cups will you need? The more cups, the more stable your picking application for larger objects.

There are so many suction cups available on the market, you will almost certainly be able to find one which suits your application. If you're struggling to choose, make sure to ask a question on the DoF forum or reach out to our team directly.

4. Decide if you need external air

We provide two vacuum gripper solutions: EPick and AirPick. The only difference between them is that AirPick uses an external pneumatic supply whilst EPick uses an integrated vacuum generator. Everything else about them is exactly the same.

Does your application need an external pneumatic supply?

Your answer can have a big effect on your application.

Reasons you might need an external supply are:

- Porous materials — Materials with a high porosity cause air leakage which can only be counteracted by an external supply.

- Low cycle times — An external supply has a higher airflow so allows for quicker pick-up and put-down times. As a result, you may be able to achieve lower cycle times.

- Security is vital — Both the EPick and AirPick have the same 10kg payload capacity. However, an external supply will allow for a higher vacuum level (i.e. a stronger vacuum). This can improve the security of the grip.

5. Pick your configuration

You've chosen your suction cups. You've chosen your vacuum supply. The final thing to choose is the configuration of your suction cups.

There is probably an infinite number of ways you could configure the suction cups.

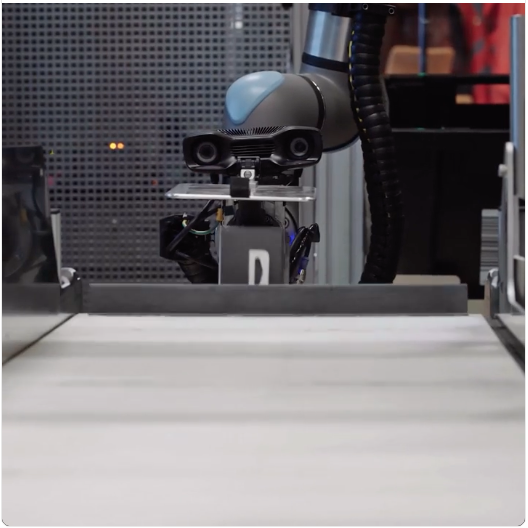

The Robotiq Surface Grippers (EPick and AirPick) come with three standard configurations: 1 Air Nodes (with 1 suction cup), 2 Air Nodes, or 4 Air Nodes arranged in a rectangle. However, these configurations are only suggestions.

You can configure the suction cups however you need. All you need to do is build a simple bracket to hold the Air Nodes in whatever configuration makes the most sense for your application.

Picking a vacuum gripper can seem daunting at first. There are a lot of different decisions you have to make.

However, the decision doesn't have to be difficult.

Just take it one step at a time.

What questions do you have about picking a vacuum gripper? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

.jpg)

Leave a comment