A Safer, Smarter Way to Palletize at Griffith Foods Colombia

When every shift ends with sore backs and tired shoulders, it’s not just fatigue — it’s a signal that something needs to change.

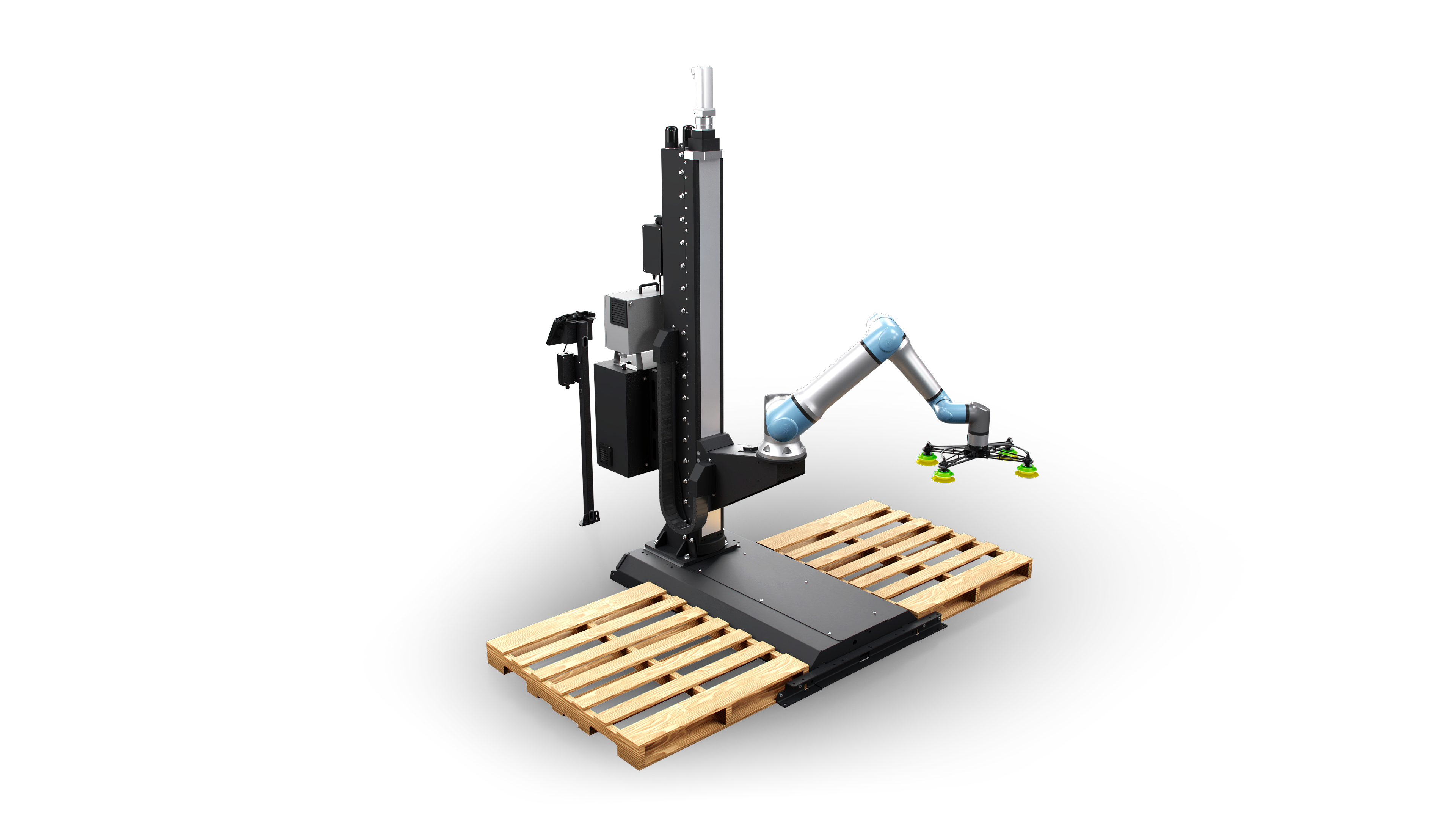

When small space meets big goals

Some wins start with a product demo. Others start with a follow-up. This one started with a dry ingredient factory in Chile and...

Back injuries, rising insurance, and one smart move in palletizing

Some problems don’t show up in your Overall Equipment Effectiveness dashboard—but they cost you big. That’s what a sauce and...

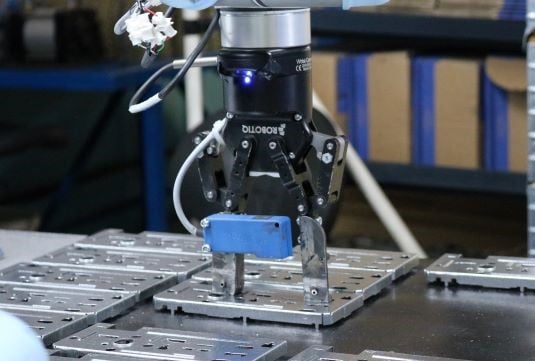

How a Growing Electronics Manufacturer Scaled Production with Robotiq Grippers

When demand surges, the last thing you want is a bottleneck in production. That’s exactly what an electronics manufacturer in...

Leave a comment