How to Choose a Parallel Gripper for My Robot?

Posted on Mar 18, 2015 in Robot Grippers

7 min read time

Ok, here you are, you decided to automate your process. You have chosen which application will be done by the robot and now you have to choose a gripper that will fit this application. There is plenty of choice, however for a simple pick and place operation with an uncomplicated part size or geometry you really want to go with a parallel gripper. Here is a short list of what you should look at when selecting a parallel gripper.

Stroke

The stroke is the distance that the fingers will cover before closing against each other. The bigger the stroke, the bigger the object, clever, eh! If you think your application will have different part sizes to handle, you may want to use a slightly bigger gripper than a smaller one. In fact, the end effector can always close fully, but is restricted to its maximum opening stroke. So, for example if you have objects from 10 to 75 mm you want to go with a gripper with a 85 mm stroke.

However, there is a down side to having a wide opening stroke. Depending on the gripper type, some grippers have to open fully before closing on the object. This means that if you are grasping a 10 mm object with a 100 mm stroke gripper, you have to consider that it will take the amount of time necessary to open to a full 100mm before closing against the object. Hydraulic and pneumatic gripper use this kind of specification because of the nature of the gripper. However, electric grippers can be programmed to open partially (in this case let's say 20 mm) and have a shorter cycle time when grasping an object. Notice also that some grippers do not close entirely, look carefully at the specs to see if your parts can be gripped properly.

Performance

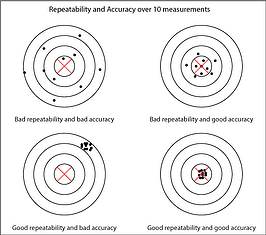

There are four main metrics that should be considered in the selection of a gripper. Speed, accuracy, repeatability and maximum force. All these specifications may be interrelated to each other, but they should be considered independently. In fact, each of these specifications have precise purposes in the application. You should establish your needs before going through all the available parallel grippers specifications.

Speed

If your cycle time is your first priority you may want to choose a gripper that offers a high speed. As a rule of thumb, pneumatic parallel grippers are faster than electric grippers. You should include the stroke length in the cycle time calculation. Consider that if the gripper has to run trough its whole stroke even at a high speed, this doesn't necessarily mean that it is faster than a slower gripper with an adjustable stroke.

Accuracy

Generally the biggest accuracy issue is due to the robot position, though you also want to consider the accuracy of the gripper. If your application requires a tight assembly task for example, you may want to have a higher accuracy than a simple pick and place task. In some cases, you may want to use a force torque sensor to help you reach the right accuracy with your robot cell.

Repeatability

In other cases, you may want to have a less accurate gripper with a higher repeatability. In the case of a pick and place matrix layout, you might want to place the parts at the exact same spot each and every time. You might want to also consider having custom fingertips that will center or replace the part in your gripper to help you achieve a good repeatability.

Force

Depending on the nature of your object you may want to limit or cranked up the force. Some grippers will have programmable force settings (electric servo grippers), while others will require air or oil pressure settings to gauge the pressure (pneumatic or hydraulic grippers). In the case of a pneumatic gripper once you have set your pressure you still might have variations due to loss in the compressed air network.

If you have various parts in your process you want to buy a gripper that can be adapted on the spot instead of doing air pressure tests for each part or material type. This will accelerate your setup time. You may also want to consider the fact that some grippers cannot reach the same force in external and internal grip... so depending on how you intend to pick your part this may be an issue.

Energy Systems

Electric

Electric parallel grippers are, in my opinion, the easiest to use. Most of the models out there have programmable stroke, programmable force and programmable speed. So it is easier to establish different settings depending on the part that has to be grasp. The connectivity is simple. You might have to buy an extra controller to support the gripper.

Pneumatic

Pneumatic grippers exist in a very wide range of models. However they are not very flexible. In fact, these grippers are limited in stroke and force settings. Their speed can hardly be set. They might require minimal energy, but they also require supplementary devices such as air hoses, valve systems and a PLC (programmable logic controller).

Hydraulic

If you have heavy applications, this is where you want to go. Hydraulic grippers are built strong and are designed to grasp big heavy objects. They are more complex to run, install and maintain but once they are set, they are there to stay. You will need hydraulic lines, pumps, valve systems and a PLC.

Robot Fit

Make sure the gripper fits the robot you have chosen. In fact, the payload, size and communication method should be considered in your choice. If the robot is strong, but does not allow the robot to grasp the part... your choice isn't the best match for your application. Make sure to consider these aspects even if it seems quite intuitive. In some cases, we have seen customers having problems with their gripper/robot fit within their application once the gripper was delivered and it was not because of the robot/gripper fit, but rather the application fit.

I hope that this article has given you some good tips on what to look for in your parallel gripper search. This is a general discussion, but it can lead you to deeper research. Buying a gripper may be complex in some cases. If you want to learn more about how to choose a gripper follow the link below and get information on the different kinds of grippers available. And... don't forget to subscribe to our blog to have weekly news on robotics.

.jpg)

Leave a comment