Unlock flexible automation with the Lean Robotics method

Automation doesn’t have to be complex to be powerful. That’s the foundation of Lean Robotics—and the key to a long-term...

What's the Difference Between Automation and Robotics?

Automation and robotics are two different, but closely related concepts. Both are part of the daily life of companies in...

How Lean Robotics Solutions Are Transforming Food and Beverage Manufacturing

In the ever-evolving food and beverage production landscape, manufacturing continues its decades-long struggle with job...

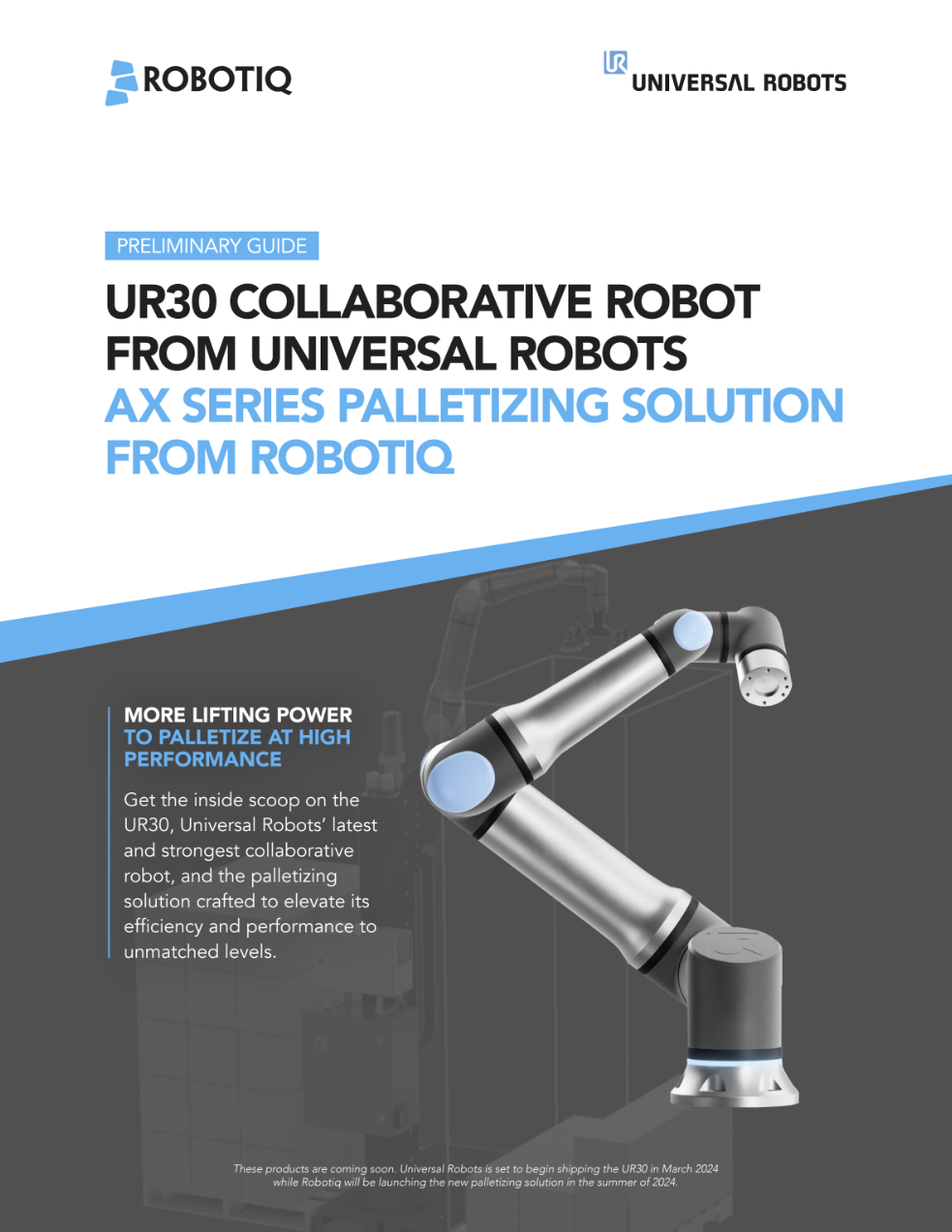

Unveiling UR30 and AX30: A Breakthrough in Robotic Solutions

As Robotiq's Senior Product Manager, along with our CEO Samuel Bouchard, I am thrilled to present Robotiq’s eBook about the...

The Human View of Robot Workers: What Do Employees Really Think?

Robot workers are transforming the way we work. There is no denying that they are here to stay… but this raises some...

7 Exciting and Effective Applications for Robotics in Retail

Robotic technology is transforming the retail industry. With robots, retailers of all sizes can automate and streamline...

Robotics in 2023: What the Latest World Robotics Report Tells Us

The use of robots and automation continues to grow at an impressive pace. But what can we expect in 2023? The latest World...

10 Robotics Predictions for Trends That Will Dominate 2023

Robots have come a long way since their early days as big, clunky machines that took up vast spaces in factories.

Today, robots...

How to Use Lean Robotics to Automate Your CNC Machine

CNC machines are amazing tools for creating high-quality parts and products quickly. Some machines are very sophisticated with...

Leave a comment