How multi-site manufacturers use cobot solutions to boost profitability—quickly and safely

Manufacturing operations are under constant pressure to deliver more with less, making cobot solutions a fast track to...

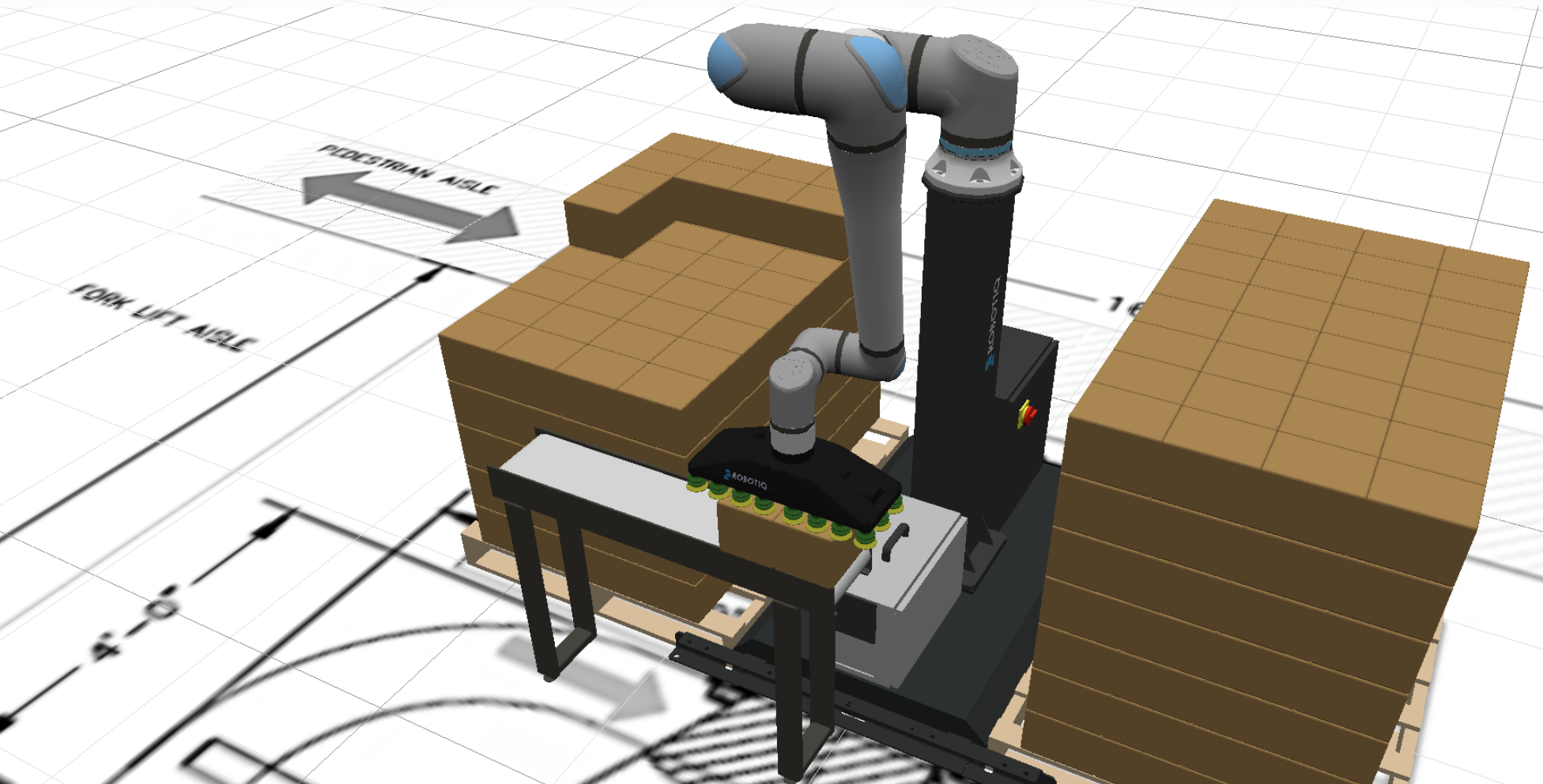

Your Robotiq Configurator just got smarter: Meet PowerPick Multi

If you’ve been using Robotiq’s Palletizing Configurator to plan solutions for yourself or your customers, you know how fast and...

Five reasons why you should join Robotiq at Automate 2025 in Detroit

Let’s be honest, automation can feel overwhelming. With all the buzz about AI, cobots, and Industry 4.0, it’s hard to know what...

Can your business afford to ignore ergonomics?

Let’s get straight to it: ergonomic injuries aren’t just a “safety” problem. They’re a business problem—one that quietly chips...

How one midwest manufacturer automated heavy lifting and unlocked new value with PCC

Labor shortages. Ergonomic risk. Turnover on the packaging line.Sound familiar? For many manufacturers, especially in the food...

A sweet win for automation: Palletizing frosting buckets with Robotiq + Alba

When your product is frosting and your goal is to move it—fast, clean, and without breaking a sweat—you don’t want to leave...

Out of hands? Out of time? Why automation is no longer optional

Labor shortages aren’t a short-term hiccup—they’re the new normal. If you’re still counting on “things going back to normal,”...

Unlock flexible automation with the Lean Robotics method

Automation doesn’t have to be complex to be powerful. That’s the foundation of Lean Robotics—and the key to a long-term...

Back injuries, rising insurance, and one smart move in palletizing

Some problems don’t show up in your Overall Equipment Effectiveness dashboard—but they cost you big. That’s what a sauce and...

-1.jpg)

Leave a comment