Why a Vacuum Gripper Can Improve Your Packing Tasks

Posted on May 30, 2019 in Robot Grippers

6 min read time

Packing tasks can be challenging for some robot grippers, especially with delicate or strangely shaped objects. Here's why vacuum grippers are a great way to improve your packing tasks.

Whether you're packing your bags for a holiday or packing product for shipment to customers, you've got to admit that packing is not the most fun task in the world. That's why it's such a good task to give to a robot!

The only problem is that packing tasks can be quite challenging. Some objects require very delicate handling, others have no obvious grasping points for a robot gripper, others are too flexible for many robot grippers. Everyone's packing task is slightly different and presents its own unique challenges.

Thankfully, there is a gripper that overcomes many of the common difficulties of packing tasks…

Vacuum grippers are flexible, customizable, and easy to use.

Here's why adding a vacuum gripper can improve your packing tasks.

The 3 purposes of packaging

First, it's helpful to go back to basics and remember what packaging is for in the first place.

There are three main purposes of packaging. Two of these are relevant to how you choose your robot gripper:

1. Protection

Packaging protects the product from bumps, knocks, and contamination. It provides mechanical strength to more fragile objects and stops the product from becoming compromised before it reaches the final customer.

As a result, this means that the robot is often interacting with the product in its most fragile form. The gripper must take care not to damage or contaminate the product itself. Vacuum grippers are generally very gentle and can be easily sanitized to avoid contamination.

2. Containment

Many types of packaging stop the product from moving around or "escaping" (e.g. spilling, leaking) before it reaches the end user.

This is why there are different levels of packaging (notably primary, secondary, and tertiary packaging). Each level of packaging provides more robust containment. For example, fragile cookies might be first packed into a bag, then packed into a box to stop the bag becoming punctured, then packed onto a pallet to stop the boxes moving around in transit.

The robot gripper must ensure that the product remains securely contained throughout all of these levels of packaging. For example, the gripper should not puncture the packaging itself or distort the packaging. Unlike mechanical grippers, vacuum grippers do not contain hard edges which could damage packaging. They also do not need to rotate the objects in order to grasp them properly, which could distort the shape of the packaging.

3. Communication

In case you were wondering, the final purpose of packaging is to communicate information about the product to logistics workers and the final customer. This is not directly related to the choice of robot gripper.

What are the gripper options for packing tasks?

Before you decide on a specific end effector for your robot, it's always a good idea to start by looking at the different options that are available. Due to the wide variation between packing tasks, almost any gripper could be suitable. It all depends on the needs of your specific task.

Here are some of the most common gripper options for packing applications:

- 2-Finger grippers — Probably the most widely used grippers across all applications are 2-Finger mechanical grippers. These can pick up most objects, and are easy to install and program. One of the disadvantages for packing tasks is that they can usually only pick up one object at a time, which can slow down the task considerably.

- 3-Finger grippers — These are similar to the previous option but they have an extra finger (or more than 3 fingers in some cases). This allows the gripper to handle round objects more securely but it doesn't solve any of the other problems.

- Dual grippers — One option for increasing the number of objects that the gripper can hold is to double up the grippers. Dual grippers are well suited to packing tasks, as we explained in our previous article 6 Things That Are Possible With Dual Grippers (+ 3 That Aren't)

- Magnetic grippers — Magnetic grippers are very useful for moving ferrous materials and some can be customized in a similar way to vacuum grippers. However, they are not very general purpose and have some other important pros and cons.

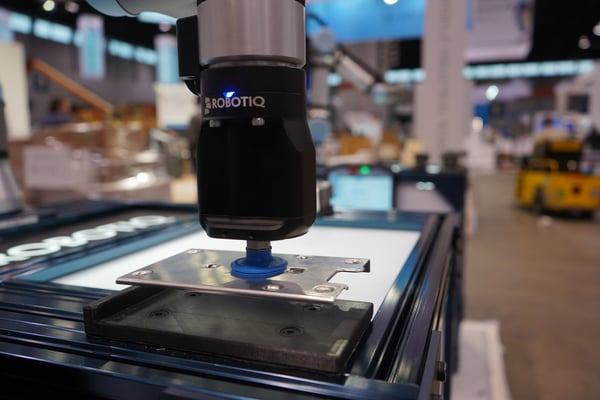

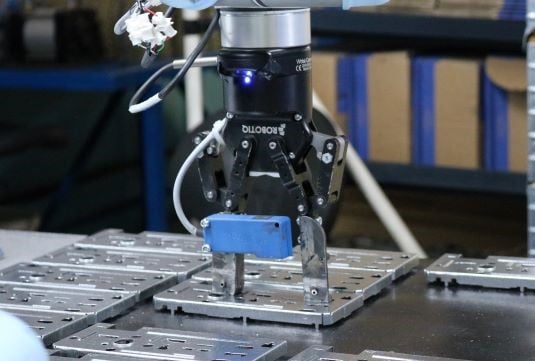

- Vacuum grippers — Finally, of course, we come to vacuum grippers. These are widely used for packing tasks, partly due to their flexibility.

It is possible that any of these grippers would be suitable for your packing application. However, there are several good reasons that vacuum grippers often come out on top for packing tasks….

5 challenging requirements that vacuum grippers can handle

Why are packing tasks challenging for some robot grippers?

Which packing tasks are vacuum grippers best suited to?

What makes vacuum grippers so flexible?

Here are 5 properties that are tough for some grippers to handle but can be overcome by using a vacuum gripper:

- Quick response — Usually, you will want to pack as many products as quickly as possible with the robot. As a result, a slow gripper can severely reduce the effectiveness of your packing task. Vacuum grippers have a fast response time, particularly when coupled with external air (as is the case in our AirPick vacuum gripper).

- Customizable — Everyone's products are packaged in a different way. Yours might be laid out in a 4x4 array, stacked on top of each other two at a time, or any one of an infinite number of configurations. Vacuum grippers are easily customizable to the exact requirements of your task.

- Delicate handling — Delicate objects can be tricky to handle with a mechanical gripper. Even grippers designed for precision handling (like our Hand-E) might not be delicate enough for some applications. Vacuum grippers are some of the gentlest grippers in the world, which is why they're widely used in the food industry.

- Able to handle strange shapes — The main problem with fingered grippers is that they can only handle objects with easy gripping features. For example, large, flat sheets of material can be very difficult to grasp. Vacuum grippers are perfect for such challenging strange shapes as they only require a surface to hold onto.

- Able to grip flexible material — Flexible packaging (e.g. filled plastic bags or plastic films) can be almost impossible to pick up with fingered grippers without risking damaging the product inside. Vacuum grippers are very good at handling flexible materials.

These challenging requirements can certainly be overcome with other grippers, but vacuum grippers are often the easiest option.

How to add a vacuum gripper to your own task

Want to use a vacuum gripper yourself? It's now easier than ever before to add a vacuum gripper to your collaborative robot.

First, you just need to pick the right vacuum gripper.

To find out how, check out our article The Simple Guide to Picking the Right Robot Vacuum Gripper.

What are the most challenging aspects of your packing tasks? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

Leave a comment