Universal Robots' UR3 VS Sawyer from Rethink Robotics

Posted on Apr 09, 2015 in Robotics

4 min read time

With the fever of Automate 2015 two major collaborative robot specific companies have come out with new cobots. These robots are designed for collaborative applications, but they do have different specifications. So, when a market is asking for a specific kind of robot, i.e. more collaborative robots, what is the point of creating two completely different robots? Here are the differences between Universal Robots UR3 and Rethink Robotics Sawyer. Let's look at them.

Collaborative Market

There really are no clear guidelines for what the robotic market is asking for. However, a couple of points should be considered in order to adapt a robot design to the latest requirements from the industry.

- Safety: Of course safety is always a big concern when it comes to collaborative robots. Even though force limited robots have been on the market for a couple of years now, it is still hard to implant this philosophy into people’s minds. Which means that a lot of safety devices and specifications should be automatically a part of the robot design.

- Payload to Weight Ratio: This specification impacts the general use of the robot and the portability of it. In fact, you want to have a robot that is capable of accomplishing multiple applications, in other words a flexible robot, that is still able to move from one station to another without using a forklift. This ratio is critical as it will help you to reduce the time for your ROI. Also, it will allow you to use your robot as much as possible on different applications while spending a minimum amount of time setting your application.

- Functionalities: I could have use the word ''application'' too. What can the robot do? What are the top applications that require a collaborative robot in your plant? If your robot can do these specific applications, this may be the key for a successful robot implementation.

So, in order to meet these requirements, what do UR3 and Sawyer bring to the market that wasn't already there?

Sawyer from Rethink Robotics

As his older brother, Sawyer is using a 7-axes platform. The robot his having a 4 kg payload and a 1,026 mm reach that seems to fit well for industrial uses such as machine tending. With a more compact design than Baxter, it is easier to integrate the robot into a limited space.

The cool thing about this robot is the vision system that monitor the surrounding of the robot but also look where it puts its hand. In fact, with its embedded wrist camera he can have supplementary information on the part it has to grasp. Here is a short list of the specification of Sawyer.

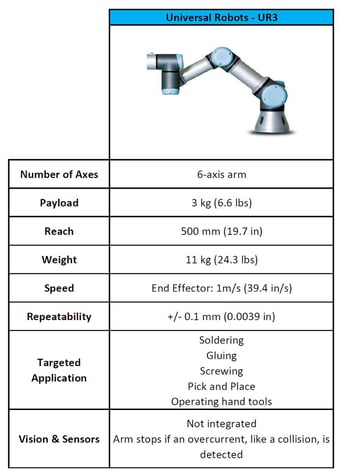

UR3 from UnIversal Robots

The smallest robot of Universal Robots his keeping the classic UR shape but a little scale down. The arm has 6-axes and has a 3 kg payload (like his name is proposing) the reach is way smaller than Sawyer and this is mainly why they don't have to same usage. In fact, with a smaller reach you want to use this robot for smaller application such as soldering, glue appliance and many others. the robot has less vision and sensors because the company want to keep things simple. Since a lot of applications do not need vision sensors, buying a robot with such sensor would be useless. This way they can lower the price of the robot and offer the same model for everyone without any extra.

So my observations are:

Rethink Robotics had some issues with Baxter and wants to sell a more compact and more rigid robot, but with the same safety features that were working well for Baxter. Easy programming, integrated vision systems and embedded screen to show the status of the robot. All good specifications that were cool to have on Baxter but with a smaller geometry. In fact, since Baxter wasn't able to do machine tending (because it was too big), the new Sawyer is now able to insert its 7-axis arm in a smaller space and with more rigidity and precision. Another cool thing about Sawyer is that its payload to weight ratio is way better than Baxter. So the robot is overall lighter and has a better payload... what more could you ask for?

Yet, the stars were aligned just right for the UR3. In fact, with a very popular UR5 and UR10 platform, they just kept the same recipe and scale it down to do smaller applications. With their UR5 and UR10 being able to support relatively high payloads, they can do machine tending, product testing and other “heavy” applications, but these robots were still quite large for smaller applications. With the increasing demand in electronic manufacturing, it was logical to bring a smaller robot to the market that could perform smaller applications. The safety features of the UR3 robot can be set depending on the environment. The weight of the robot is ridiculously low and can be transported very easily.

So both companies had really good reasons to launch their robots. Either to fill a gap in their product line or to adapt their product to actual applications that the market is interested in. So, they had pretty legit reasons to put out these robots.

Anyways, these are just my observations! In the meantime, look at our updated version of our eBook on Collaborative Robots it includes these 2 fellas. Let us know what you think about the new version, comments are always appreciated.

Leave a comment