New Mobile Manipulator from OTTO Motors

Posted on Jun 14, 2016 in News

3 min read time

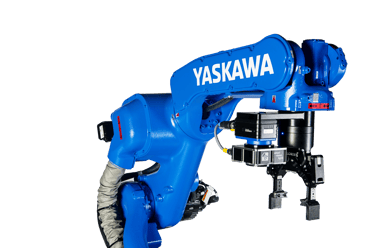

Ready for industry 4.0? Well OTTO Motors is. With their recent partnership with Yaskawa/Motoman, the mobile platform manufacturer is working to enhance their range of applications. Imagine all the stuff you can do with a 1500kg payload platform running around your warehouse fully autonomous, then add a large range manipulator and a versatile end-effector... Well, I don't see what it can’t do. Let's take a look at what the next industrial revolution has to offer.

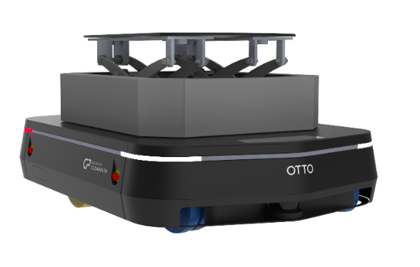

The heavy duty mobile manipulator is the result of the huge R&D effort from Yaskawa and OTTO Motors (you most likely know their research division Clearpath Robotics). Although the solution is still in development, the first prototype uses the OTTO 1500 that has a 1500 kg payload, Yaskawa’s fully integrated Motoman MH12, and a Robotiq 2-Finger 85 Gripper. The cell is completed with a wrist camera.

What Does it All Mean?

All of these mechanical devices put together are a real piece of modern technology. With proximity sensors, path planification and wireless communication, the OTTO 1500 can move around the plant without minimal risk of injury to the workers – it uses SLAM technology to detect and move around objects in its path. It receives commands and safely navigates to its asked position without using any infrastructure.

The manipulator is a 6-axis Yaskawa/Motoman MH12 robot with a 1,4 m reach and a 12 kg payload. This means that it can carry a lot of different stuff without being limited in payload capacity. The robot can be synchronized with different sensors on the platform and remains safe for the human worker around it.

The end-effector (Robotiq 2-Finger 85) has an adaptive technology and is fitted with custom made fingertips that allows the robot to carry a wide variety of things and can also execute different tasks. This end-effector has a regrasp and a self-locking technology allowing for a virtual 100% secure grip. This Gripper can mechanically adapt to different objects. In other words, you always send the same programming line to the Gripper and it will stop when it detects an object.

For the camera, well this is the cherry on the cake. The camera can locate the part/box that has to be grasped. It can also predict if the parts are too close from each other in order to grasp correctly by replacing them in the right order. The addition of a camera is pretty much essential when doing kitting or bin picking in the warehouse, just as this new platform does.

What Are the Main Applications?

Well, as the solution is very flexible and has a bunch of sensors, the mobile manipulator is designed for indoor applications such as warehousing. When talking about the application itself, it is kind of hard to say because it is still in development. But from what we can see, this full solution has the potential to be used for bin picking, process specific manipulation, even mobile machine tending. The platform can do a breadth of tasks as long as the repeatability and/or the accuracy of the cell reaches your expectations. With a +/-25mm repeatability, it is pretty repetitive for something that runs around a warehouse. And don't forget that the camera is there to see what is going on in the bin, so the platform doesn't have to be precisely accurate to grasp.

If I Don't Want to Carry a Grand Piano, Is There Something for Me?

OTTO Motors now has 2 models of self-driving vehicles: the OTTO 1500 and the OTTO 100, which can be customized to fit your specific needs. Configurations include a pick up and drop off station, a conveyor, and a lift; all of which can be fitted on top of your platform.

OTTO Motors now has 2 models of self-driving vehicles: the OTTO 1500 and the OTTO 100, which can be customized to fit your specific needs. Configurations include a pick up and drop off station, a conveyor, and a lift; all of which can be fitted on top of your platform.

For whatever use you would like to do, there is probably an OTTO solution for your needs.

P.S. They also have a pretty sick ROI calculator on their website. Take a look at it!

It is really impressive to see what came out from our friends at OTTO Motors and we are pretty stoked to be part of their mobile manipulator. Let's see where their platform can go and which company will be down to make an AMAZON of themselves by using an OTTO self-driving vehicle.

Leave a comment