Cobots in Packaging: The State of the Industry in 2018

Posted on Aug 14, 2018 in Collaborative Robots

5 min read time

This year, a staggering number of companies are using cobots for packaging. Here's the state of the packaging industry in 2018.

Packaging is a wonderful application for collaborative robots. First, it's a vital but non-value-added task—perfect for cobots. Moreover, today's industries have an ever-increasing need for packaging.

You may not agree ideologically with the rise in packaging—after all, do supermarkets really need to wrap each fruit individually?—but companies must meet customers' packaging demands to scale. Your business is faced with a choice: either employ more people or try another way.

When scaling is a problem, robots are often a good solution.

Over the last three years, the packaging industry has adopted cobots and other automation en masse. The recent Evolution of Automation Report from the Association of Packaging and Processing Technologies found that a staggering 90 percent of food processing and packaging companies now rely on robots.

In this article, we take a look at the state of collaborative robotics in the packaging industry.

What is driving the rise in robot packaging?

Nine out of ten packaging companies are now using robots. According to one report, the cobot market has an estimated 57 percent Compound Annual Growth Rate (CAGR) between now and 2023.

We think that's great. But why are companies moving to automation?

Some might say that robots are the future, and so mass adoption is inevitable. However, we know that businesses don't adopt technologies unless there is a real need.

In a recent interview with Packaging Digest, Universal Robots' Daniel Moore explained: "At most every plant I visit, managers complain about labor shortages. Plants that want a hundred workers only have ninety. Plants that want ten workers only have eight."

The shortage of skilled labor is one of the top reasons companies adopt collaborative robots. With fewer hands than needed, businesses are unable to keep up with rising packaging demands and, as a result, are unable to scale quickly.

The recent Evolution of Automation Report from the Association of Packaging and Processing Technologies found that 90% of food processing and packaging companies are now using robots.

The recent Evolution of Automation Report from the Association of Packaging and Processing Technologies found that 90% of food processing and packaging companies are now using robots.

The top six trends behind this rise

The Evolution of Automation Report outlined six driving forces behind the increase in packaging automation:

- Skilled labor shortages.

- Global increase in product demand.

- Rising demand for flexible manufacturing.

- Need for more consistent quality.

- Decreasing operating costs.

- Increased smart machine technology and cobots.

With these 2018 trends, it's no wonder the packaging industry embraced cobots.

The biggest challenge for packaging cobots

Of course, there are still roadblocks stopping some companies from adopting cobot packaging.

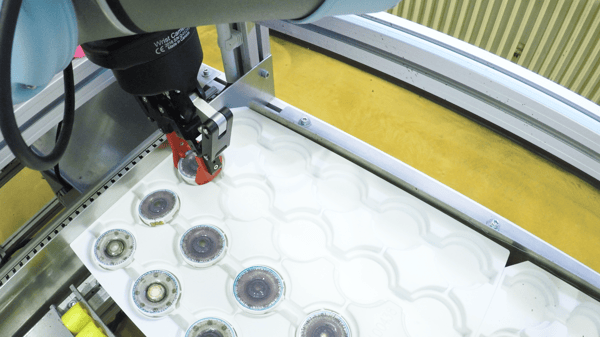

In another Packaging Digest interview, Mike Fair of Rethink Robotics said that cobots' greatest evolution, both in packaging and in general, is their integration with other technologies, like end-of-arm tooling and smart sensing.

UR's Daniel Moore agreed, bringing attention to their UR+ developer ecosystem, which allows peripheral companies like us to develop easy-to-integrate add-ons for Universal Robots.

In a way, this challenge is actually quite a positive one. It shows that many third-party peripherals are now available for collaborative robots, which allows companies to choose the right products for them.

However, this challenge also means that robot manufacturers must work hand-in-hand with peripheral manufacturers to ensure that products are easy to integrate. That's why we chose to release our Hand-E gripper alongside the new UR e-Series at this year's Automatica.

Your biggest concerns about cobots

Although cobots' popularity is one the rise, some people still have reservations.

UR's Daniel Moore cited safety as the biggest concern among potential cobot users. Safety is important for packaging tasks, particularly when the robot will be operating alongside human workers.

For Mike Fair of Rethink Robotics, the biggest concern from customers was choosing applications. A common question he gets is, “What applications can I deploy most successfully [with a cobot]?”

We agree: choosing the right application is vital. You can simplify the robot integration for yourself and your team by picking a simple task for your first deployment. That's why we developed the lean robotics framework to help businesses to get started with cobots as quickly and easily as possible.

Which industries benefit from packaging cobots

No matter what industry you're in, packaging probably forms part of your operations. There is potential to use packaging cobots in a wide variety of industries.

Four examples we have covered before on the blog are:

- Consumer goods. In Five Ways Unilever Uses Robots to Keep Up, we outline how consumer-goods giant Unilever uses packaging robots to boost product variety and combine different product lines.

- Craft brewing. Cobots are a great option for small to medium enterprises (SMEs) where larger forms of automation are too costly. In How to Scale-up a Craft Brewery With Robots, we explain how cobot packaging can increase productivity in craft breweries without compromising the artisan quality of the product.

- Food packaging. The food industry has integrated robotics at almost every stage of production. In Top Seven Robotic Applications in Food Packaging, we show how cobots are being used for boxing and palletizing applications.

- Packing your bags. Do you travel a lot? If so, this fun application might be perfect for you. Our CEO Samuel Bouchard found it at a trade fair. It shows a robot using our 3-Finger Gripper to pack the suitcase of the fictional Mr. and Mrs. Smith. See the video in Bored Packing Your Baggage? Adaptive Gripper could be the Solution!

From their humble beginnings just a few years ago, cobots have now truly taken hold in the packaging industry.

Which packaging tasks could your business give to a cobot?

Leave a comment