Clearpath Grizzly and Husky More Flexible Than Ever

Posted on Feb 24, 2015 in News

3 min read time

Clearpath Robotics started as four University of Waterloo mechatronic engineering students trying to decrease the casualties of war. This noble cause eventually led Clearpath to become a robotics company developing out of the box platforms and custom projects to automate the world's dullest, deadliest and dirtiest jobs. Now with their upgraded version of the mobile manipulator, the possibilities are more diverse than ever.

New Mobile Manipulation Platform

Clearpath has recently partnered with the Danish robot company Universal Robots for some of their manipulating platforms. In fact their Husky and Grizzly models will now be fitted with UR5 and UR10 respectively. As the platform was already equipped with different sensors for navigation, the addition of the Universal Robots arm will now enable customers to perform more tasks with it. Previously, you had to deck out the platform yourself even though it could be fitted with pretty much anything you wanted to use on it. From navigation to exploration, a lot of different applications can be done with these mobile platforms. However, grasping objects, closing valves or whatever other manipulations you wanted to accomplish was a little more complex since there was no pre-installed robotic arm attached to it.

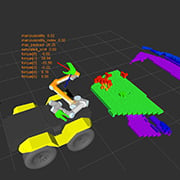

With the addition of a flexible robotic arm such as the UR5 or UR10 paired with a Robotiq Gripper, an almost infinite possibility of manipulation is opened up. The largest version (Grizzly) of the manipulator is equipped with a UR10 and a Robotiq 3-Finger Adaptive Gripper. The smaller version of the manipulator (Husky) is equipped with a UR5 and a 2-Finger 85 Adaptive Gripper. These combos can be programmed on a ROS platform which enables the user to do various tasks by including all the different peripherals that are available on the platform.

“The arm will be able to plan around obstacles, work with the sensors on the robot, see things in the environment (determine them as obstacles), and avoid them just as you would with our other platforms avoiding things in 3D space along with a lot more.” - Julian Ware, Research Products General Manager

The Grizzly Manipulator is able to reach speeds of 19km/h, handle a 10kg payload and run autonomously for 12 hours. It was previously designed as a research project, but the company is now reaching more industrial applications. All the mobile platform's programming, vision system, simulation and robot/gripper programming are done on open source software that are suited for ROS. This allows the user to reach a more complex level of automation since you don't have to develop your own program, you can start from where someone else left off. You can also manage all the different peripherals using a common platform.

Clearpath

The company has a solid team of experts that can design an entire mobile manipulator specific to your application if needed. From system design, perception/mapping, navigation/control and simulation, the team has all the tools necessary to realize an all-inclusive package. They also provide solutions for ground, air and water exploration.

Universal Robots

Universal Robots develops and sells industrial robots that automate and streamline, monotonous, and mundane industrial processes. They enable the production department to assign their staff to jobs they enjoy; jobs that provide them with a challenge and add value to the company.

Robotiq

Our goal is to enable all manufacturers - especially those dealing with high mix production - to take full advantage of robotics. We work with robot manufacturers, system integrators and end-users to automate applications that require flexibility. Robotiq sells product in more than 30 countries, through our global network of partners.

We are really excited about the new mobile manipulator and look forward to seeing the cool applications that will no doubt be developed with it. In the mean time you might be interested in the document that we have put together on the different research projects that are done with our 3-Finger Adaptive Gripper. To take a look at it, follow the link below.

Leave a comment