Adjustable Safety Features on Universal Robots

Posted on Sep 14, 2015 in Safety

2 min read time

The safety of collaborative robots is sometimes put in doubt because of the fact that it is a new concept. In fact, just because it can work alongside humans, doesn’t mean that people are comfortable working alongside robots. To avoid such concerns, manufacturers have develop ways to reduce or eliminate the possibility of impact. In fact, by reducing the speed of the robot while the worker is working beside it reduces the possibility of contact with the worker.

Fixed Safety Zone

Many collaborative robot manufacturers have develop ways to reduce the speed of the robot arm when the robot is in a certain zone. The first way to do this is to establish fixed reduced speed areas where the robot will reduce its speed while in this zone. An area established by planar points is virtually placed in the robot workspace and once the robot enters this virtual space it will reduce its speed for the next operation it is programmed to perform. The following video explains how this can be done with a Universal Robots.

Video from Cross Automation

This kind of safety feature would be close to the 'Safety-rated Monitored Stop' as described in the ISO 10218 standard. This new term applies to the robot drive system where it has limitations built-in to ensure safe speeds and/or torques as explained above.

Variable Safety Zone

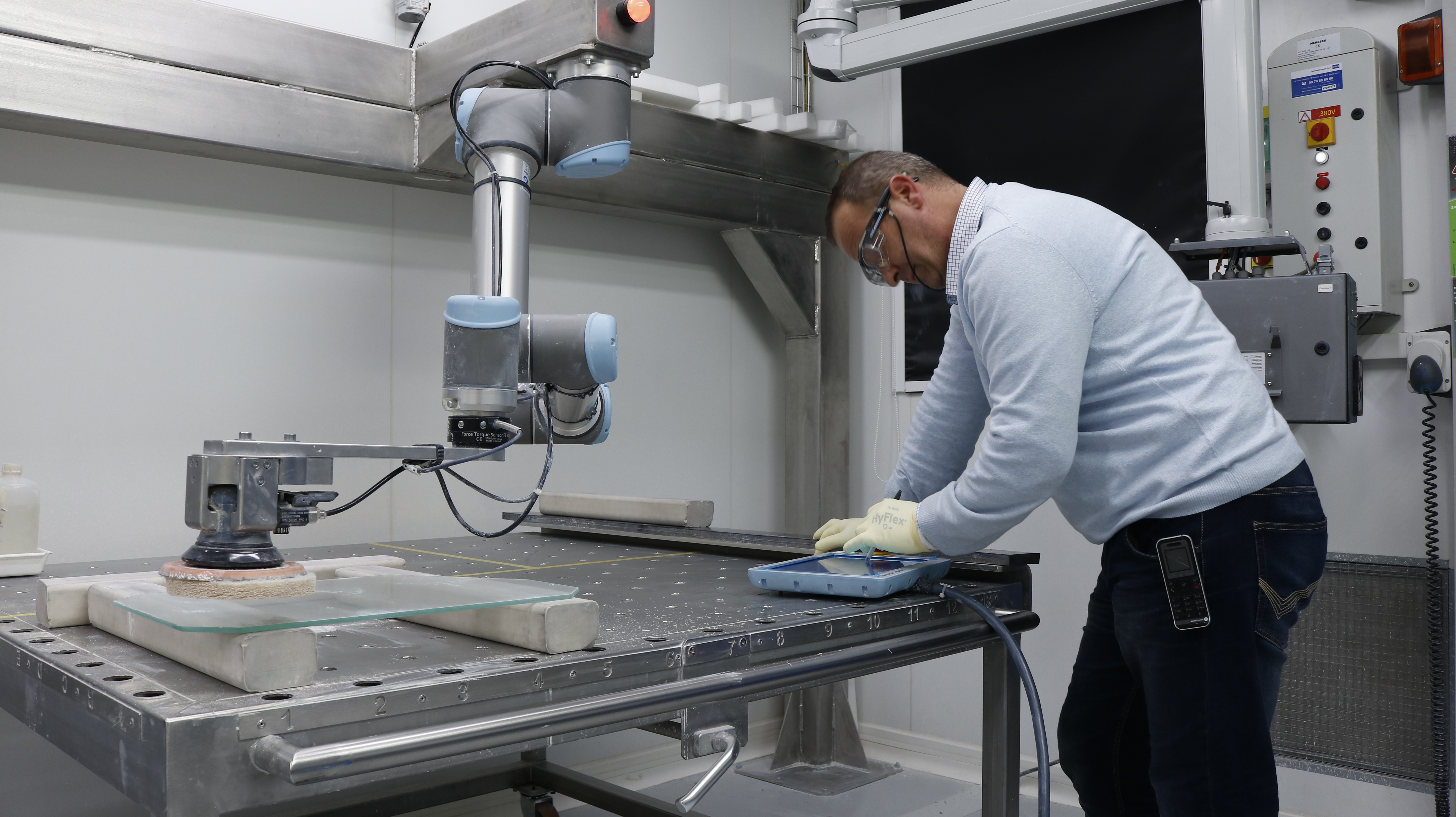

If you want to go a step further in your safety features you can add a vision or laser system that can monitor the robot’s surroundings. By doing this you can establish different safety zones for different robotic functions and program the robot react to these zones. In fact, in this video, if a worker is entering the reduced speed safety zone the robot will reduce its speed but will still continue to achieve its task. If you enter the next zone which is closer to the robot, the robot will fall into the stop safety zone, where the robot will brake completely and stop all its motions. Once the worker exits this zone, the robot will resume its motions and continue its program from where it left off. Notice that the robotic cell is equipped with a light that broadcasts the state of the robot. Orange for reduced speed, red for safety stop and green for full speed ahead. You should also notice that the robot has a fourth mode which is an emergency stop. This is the same as any other robot where the robot will stop all its motions and will need a reset before going back to its program.

Video from Axis Systems

This kind of safety feature would be closer to the 'Speed and Separation Monitoring' as described in the ISO 10218 standard.

If you need further information on how to realize a safe robotic cell you may want to look at the following document that goes into more detail on collaborative robots and the risk assessments necessary when implementing a robotic cell.

Leave a comment