11 Helpful Questions About Machine Tending with Vacuum Grippers

Posted on Sep 19, 2019 in Robot Grippers

5 min read time

Machine tending is one of our most popular tasks for new cobot users. You can now use a vacuum gripper! Got some questions? Here are some answers.

Just when you thought that you had it figured.

Just when you thought you'd made all the decisions that you'd have to make.

Just when you thought "Okay! We're going for a collaborative robot and it's going to do machine tending."

… a new decision appears out of nowhere…

Should you use a vacuum gripper for your machine tending task?

You probably have some questions. Here are some answers.

1. Why are vacuum grippers better than fingered grippers for machine tending?

The simple answer is "they aren't!"

Vacuum gripper aren't inherently better than fingered grippers for all machine tending tasks.

But, you're not trying to achieve "all machine tend tasks" are you?

You're trying to deploy your specific machine tending task in your unique situation. In this case, it's possible that a vacuum gripper will better suit your needs, but it's also possible that a fingered gripper will be better suit your needs. The quickest way to find out exactly which technology your task needs is to ask an implementation coach.

2. Why are vacuum grippers suddenly an option for machine tending?

They're not!

Vacuum grippers have been available for robots for years. They are the most popular type of robotic gripper in some industries. However, it's only recently that we have introduced our own vacuum grippers here at Robotiq…

… but, there's more too it than just saying "we have a vacuum gripper so we're talking about them now" (we've talked about them in the past anyway).

The difference now is that suddenly vacuum grippers are a feasible option for any new cobot user. Traditionally, vacuum grippers are very tricky to purchase and integrate. You had to make many decisions, make a load of calculations about vacuum levels, and purchase different parts from different suppliers. Now, the decisions you need to make are minimal.

3. Do I need a pneumatic supply?

Maybe, but not necessarily.

This is an extremely common question. In the past, all vacuum grippers needed an external air supply. Now grippers like EPick have an in-built vacuum generator. You can add an external supply to increase the vacuum flow, but only if your task really needs it.

4. Is it easier or harder to control a vacuum gripper?

Compared to a fingered gripper, potentially a bit easier but basically the same.

Both fingered grippers and vacuum grippers are very easy to control. You just move the robot arm to wherever you need it, activate the gripper, and you're done! Simple.

There's only one thing that might make vacuum grippers a bit easier to control than fingered grippers. They do not require such precise poisoning of the gripper to approach a grip feature from the right direction. On the other hand, vacuum grippers do work better when the lifting force is parallel to the object — which is not the case with fingered grippers — so, in the end, they come out about equal.

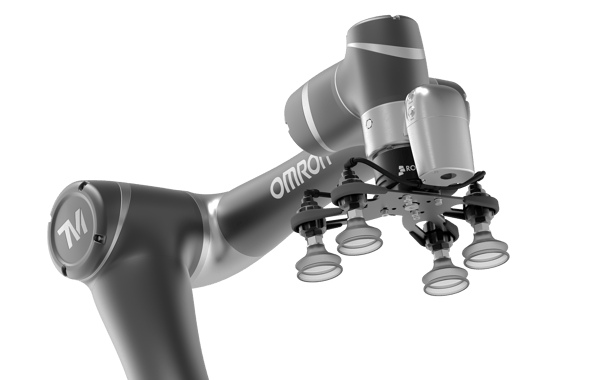

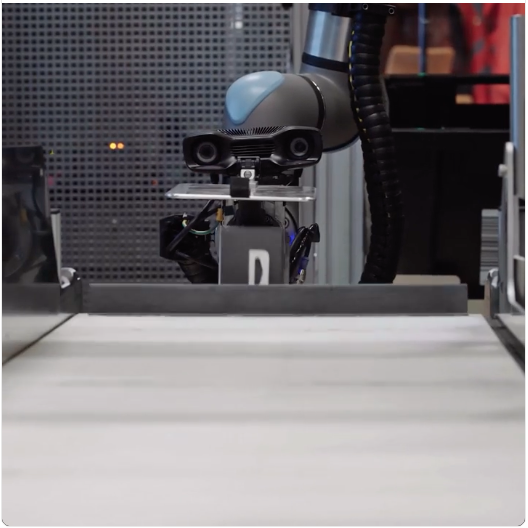

You can now use a vacuum gripper for Machine Tending.

You can now use a vacuum gripper for Machine Tending.

5. What type of machines are best suited to vacuum grippers?

This is a tough question to give a definite answer to.

We sometimes think of machine tending as being only about tending CNC machines. In reality, a huge range of machines are suitable for machine tending (e.g. labeling machines, product testing machines, inspection machines, etc). Vacuum grippers can be compatible with any of them, but the specific needs of your task will determine what type of gripper you need.

6. Will a vacuum gripper make it easier to interface with my machine?

Probably not, except in some unique situations.

Interfacing with the machine is often the hardest part of a machine tending deployment. We usually advise people to use low-tech solutions — e.g. pressing the start button on the machine with the gripper rather than trying to send a digital message to its controller. Either way, there won't be much difference unless the start button on the machine is more easily activated by one type of gripper.

7. Will a vacuum gripper drop the parts?

Not if you use the gripper correctly.

Many of us intuitively feel like vacuums cannot grasp objects as securely as fingers can. This is understandable. After all, we don't have big vacuum cups at the end of our own arms, do we? We have fingers. However, vacuum grippers can be as stable and powerful as fingers (you can even climb up a wall using vacuum cups). The EPick and AirPick vacuum grippers have a payload capacity of 10kg, which is the same as our 3-Finger gripper and more than our 2-Finger grippers.

8. Is my machine tending task suited to vacuum grippers?

It's quite likely!

Vacuum grippers are extremely versatile and are compatible with many machine tending tasks. However, this is perhaps the wrong question. Instead, you should be asking "Is a vacuum gripper the best solution to my unique needs?" We can help you to work that out.

9. Will a vacuum gripper work if the objects are dirty?

Possibly. There's a good chance, yes.

It depends on the level of dirt and the type of vacuum gripper that you have. Dirt, dust, and grease can all affect the vacuum quality. If the vacuum cup loses too much of its seal, it could drop the object. A bellows-type vacuum cup can help with this and our AirPick gripper can account for a less-than-perfect seal around the edges of the vacuum cup.

10. Will there be a speed increase compared to fingered grippers?

There often is!

Fingered grippers are great, but they always add extra cycle time because you have to wait for them to close around the object. You can reduce the grasping time by reducing the width of the "open" position, but you can't eliminate it. Vacuum grippers can grasp an object extremely quickly, especially if you use AirPick which has a high flow rate.

11. Do I need a vacuum gripper if I already have a fingered gripper?

Maybe… or maybe not.

It would be wrong of us to say "Buy a new gripper!" if you don't really need one. If you already have a fingered gripper for your task, you should only get a vacuum gripper if it will actually improve your application.

To find out if your task might benefit from a vacuum gripper, feel free to send us a question directly.

What question did we miss out? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

.jpg)

Leave a comment