10 Palletizing Extras That Improve Robot Performance

Posted on Aug 29, 2019 in Palletizing

6 min read time

Robot palletizing is an extremely popular automation task. It doesn't require much tech but some extras, e.g. vacuum grippers, can improve robot performance.

Palletizing is one of the most common robot applications in many industries. All products need to be packaged in one way or another and robots are often better suited to palletizing tasks than humans.

You don't need much technology to get started with palletizing. With a collaborative robot, you just need a cobot, a gripper of some sort, and a palletizing wizard. However, there are some extras that you can add to your robot cell that improve the performance even further.

Here are 10 great extras that can boost the performance of your palletizing robot.

First… do you really need extras?

Before you jump into buying some new technology, it's important to first consider if your robot cell actually needs it. You should only invest in new tech if there is a good reason to do so.

Will the extras really improve the operation of the cell?

Will they add measurable improvements?

Will the benefits outweigh the cost?

Every time you add new technology to a robot, it increases the overall complexity of the cell. More complexity is almost always a disadvantage. Whatever problem you are trying to solve by adding the new technology, make sure you have considered all the possibilities for how you could solve it, and then make sure the benefits outweigh the cost.

10 Palletizing Extras That Improve Robot Performance

All of the extras listed below have the potential to improve your cell performance… assuming that they are applied in the right circumstances.

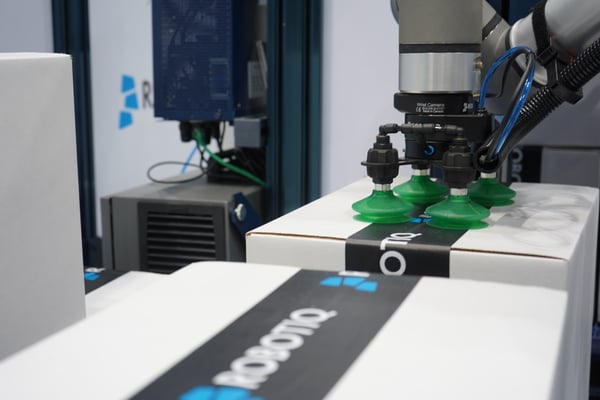

1. Vacuum gripper

This one of the most popular additions for industrial robot palletizing. Vacuum grippers are extremely flexible, allowing you to securely pick up a variety of different objects without needing to alter the gripper in any way. They are also very gentle and usually grasp objects much quicker than fingered grippers with similar properties.

To find out more, check out our article: Why Vacuum Grippers Are Really the Best Option for Robot Palletizing.

2. Conveyors

If you were to search for images of palletizing cells online, you would see a lot of conveyors. They are a very common way to bring products into and out of the robot cell because they streamline the whole production process. However, despite their popularity, it's important to note that adding a conveyor is not always simple. You might need to add extra sensing, such as robot vision or an alternative, to detect the position and orientation of the moving objects.

3. Palletizing software

You can find specialist software which is designed to aid autonomous palletizing operations. These packages range from simple software tools which arrange objects in a regular pattern to complex tools which incorporate sensing, AI and more to automatically adapt to differently sized objects.

But, you don't necessarily have to add complex software to your cell. Some collaborative robots already include a palletizing wizard which makes programming very easy.

4. Mobile robot base

Mobile collaborative robots are really on the rise just now. Adding mobility allows your palletizing robot to become even more flexible. For example, the robot can to move itself to the product instead of requiring the product to come to the robot.

There are some important things you need to consider before investing in a mobile base, which you can read about in our article How to Decide If You Need a Mobile Cobot.

5. Custom grippers

Customization is quite common in palletizing. With a custom gripper, you can ensure that the robot is perfectly suited to handling your products. You can either design a completely custom gripper — which is a lot of work — or you can adapt an existing gripper with custom fingertips. Either way, there is a bit of design and engineering work involved.

6. Robot vision

Robot vision allows the robotic system to detect objects to be palletized and adapt itself to them. It allows your palletizing robot to handle objects of different sizes, shapes, and orientations, which may not be possible without vision. Although some robot vision systems can be complex to use, others are very simple to program for palletizing. Users of our Wrist Camera have been able to achieve palletizing tasks very effectively.

7. Hazardous material handling

Packing hazardous substances is a perfect task for a palletizing robot. The less that humans are in contact with dangerous materials, the safer your workspace will be for everyone. Some hazardous materials won't require any extras for the robot to handle them. Other substances may need, for example, a protective covering to reduce the chance of contaminating the robot.

8. Dual grippers

If you are using fingered grippers with your palletizing task, your cycle time is often restricted by the fact that you can only pick up one object at a time. Adding a dual gripper can significantly reduce this cycle time by allowing the robot to hold two objects at once.

You can calculate the productivity boost of the dual gripper by following the instructions in this article and you can learn more about palletizing with dual grippers in our article 6 Steps to Optimize a Palletizing Cell With Dual Grippers.

9. Force feedback

Force feedback can add some very useful features to a palletizing robot. For example, a force sensor can be used to detect the weight of the products as it is packing them. This essentially turns the robot into a combined packing and inspection robot. Force sensors can also be used to differentiate between different products without the need for more complex sensing like robot vision.

10. Multiple robots

Finally, if you want to boost the productivity of a palletizing cell a lot, you can add another robot. This can help, for example, if you have a fast flow of products coming into the cell and they need to be palletized more quickly than a single robot could manage. Of course, it is then important that the robots can communicate with each other, but this is quite easy if you are using the right tools.

If any of these extras sound like they might be beneficial for your robot cell, click on the link within the section to learn more about it.

Find out more about our palletizing solution on our product page.

In what way does your palletizing task need to be improved? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

-2.png)

-1.jpg)

Leave a comment