The Palletizing Solution: The Last Word in Pallet Automation

Posted on Feb 01, 2022 in Palletizing

5 min read time

Which task should you automate first with a robot? For many manufacturers, The Palletizing Solution offers a perfect balance of high benefit and easy deployment. And it now comes in several forms to suit every requirement.

Like most manufacturers, you probably want to automate some manual tasks in your business. In the last few years, businesses have started installing robots at record rates. You know that your business needs to catch up or you risk slipping behind.

But, which is the best application to choose?

Many companies are finding huge benefits by choosing robotic palletizing as their first robot automation project. Today's palletizing robots are not the huge, complex, expensive solutions that have long dominated automated palletizing. They are smaller, more accessible, and easier to deploy than ever before.

We're announcing our brand new range to suit any manufacturer's palletizing needs.

With our 2 series of palletizing robots, we think that The Palletizing Solution will be the last word in accessible palletizing automation.

Think you don't have the resources for palletizing automation?

Companies often mistakenly believe that palletizing automation is beyond their resources. This is understandable — most videos of palletizing robots you can find online involve huge robots moving huge volumes of product every minute.

Does it still make sense to invest in a palletizing robot if your needs are more modest?

One of the reasons we introduced The Palletizing Solution was to help make the answer to that question a resounding Yes!

Even if you are shipping much lower quantities of product, robotic palletizing is likely suitable for your needs. You don't need to ship hundreds of pallets a day to get the benefits.

As Manfred Galetzka, Technical Manager at manufacturer Hoch Oblaten, said in our recent case study:

"Just do it. Don't wait. Because the time you're taking to think about whether or not you can [palletize with a robot] is lost time. As soon as you do it the robot earns money."

Adding a palletizing robot is much easier than you might think.

4 compelling benefits of using robotic palletizing

What are the benefits of replacing your manual palletizing process with a robot?

The 4 most common benefits that people experience are:

- Improved ergonomics — Manual palletizing can be a significant cause of workplace injury as workers need to move heavy boxes repeatedly over long shifts. Robotic palletizing removes this strenuous task from their jobs, reducing injury.

- Saved time — The time-consuming task of manual palletization is one that companies often struggle to fit alongside their worker's other tasks. Robotic palletizing means that workers have more time to spend on other tasks.

- Better use of human potential — Let's face it, stacking boxes on a pallet is not the best use of your people's talents. Robotic palletizing means they can spend their valuable time on more value-added tasks.

- Helps tackle labor shortages — One of the causes of the current spike in robot adoption is the labor shortages that many manufacturers are experiencing. It's going to be hard to find willing people to do palletizing as their job, but a robot will be more than happy to do it!

The Palletizing Solution by Robotiq

Since we first introduced our AX Series Palletizing Solution in October 2020, we have seen a huge demand to automate this fundamental task.

This high demand was not surprising. Customers had been telling us for a long time that palletizing was an unwelcome task among workers and that they would like to automate it as soon as possible.

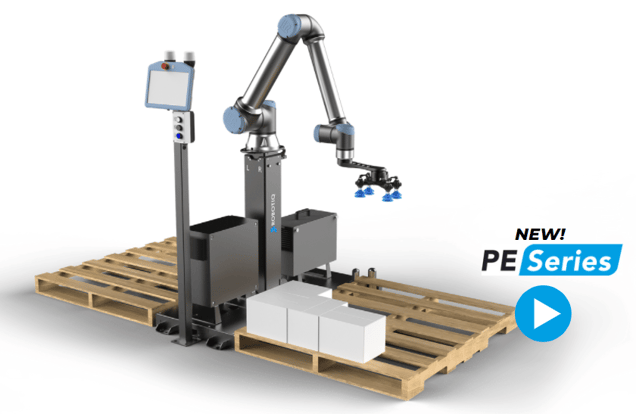

For 2022, we have expanded our range of solutions for robotic palletizing to incorporate even more use cases. We have introduced a new series (the PE Series) for smaller palletizing tasks. These 2 series — and any that come in the future — now fall under the category called The Palletizing Solution.

The AX Series for extra reach

The AX Series Palletizing Solution has been successfully deployed into many facilities already. Thanks to its fully integrated vertical axis, it supports higher pallets than many of the alternative solutions on the market.

Its high performance means that it earns a Return on Investment (ROI) faster than with other collaborative robot solutions.

Some key features include:

- Can fill stacked pallets of a height of up to 2750 mm with its fully integrated vertical axis.

- Supports all ISO standard pallet dimensions.

- Payload capacity of up to 16 kg.

- Integrated pallet sensors to detect that pallets are in place.

- Can fill up to 2 pallets and box patterns simultaneously.

- Has a maximum throughput of 13 boxes per minute.

- Material Handling Copilot makes programming easy.

The PE Series for simpler palletizing

Our latest addition to the Robotiq solutions family, the PE series is designed to be even more accessible and is optimized for smaller pallets.

A key distinction of the PE Series is that it includes a manually adjustable pedestal instead of the actuated vertical axis of the AX Series. This makes the solution more affordable and is perfect for pallets that need to be stacked to a shorter height.

As well as those features of the AX Series listed above, features that distinguish the PE Series include:

- Can fill stacked pallets up to 1500 mm with its manually adjustable pedestal.

- A teach pendant stand with internal cable routing to keep the solution as a completely self-contained unit.

- An operator box to allow easy programming right next to the robot.

- Tower lights to indicate the operation of the robot with clear safety lighting.

How to pick which Palletizing Solution to use

Want to get started with your own robotic palletizing solution?

Not sure which of our solutions will be right for you?

The best place to start is to check out our Palletizing Solution page. This includes a link to our interactive Palletizing Configurator where you can customize the solution for your unique situation.

There's even an augmented reality app for your phone that you can use to visualize the solution in your facility!

What questions do you have about robotic palletizing? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

-2.png)

-1.jpg)

Leave a comment