The Internet of Things: Why Robotics is Ahead in Top Trends

As everyone starts to look for "the big technology trends of 2016", it seems that one technology is overshadowing all others - the Internet of Things. We take a look at why robotics is actually ahead of the game with this new and upcoming trend. Some industrial robotic companies have been involved with it for 10 years. It seems that the Internet of Things is already upon us, so we'd better get prepared for it.

It's around this time of year that people start making a lot of predictions about the future (ourselves included, here were our predictions for 2015). Technology journalists get all excited about what they think will be the big "Tech Trends" of the New Year. For 2016, some popular upcoming robotic trends are:

- Affordable social robotics (e.g Pepper and Buddy),

- An increasing use of robotics in mining and agriculture,

- Connected autonomous cars, drones, drones and more drones,

- Cyborgs and sexbots,

- and a proliferation of robotics startups.

But, one Tech Trend is overshadowing them all for the upcoming year: The Internet of Things (IoT).

Image: Sloane Review. MIT.edu

Image: Sloane Review. MIT.edu

Predictions about the IoT being "the next big thing" are coming from all technology sectors, from information technology and computer security to investment. It's not all hype, there are real devices being produced. At the end of 2015, IoT devices had begun to show up on the market, including a smart cup which tells you how much water to drink and a stealth gadget which ensures the security of other connected IoT devices.

In fact, in the field of industrial robotics, the IoT has been well underway for a few years now. Back in 2013, one of our top takeaways from RoboBusiness 2013 was how IoT is an important concept in robotics. Then, in our recent takeaways from RoboBusiness 2015, we heard about numerous examples of companies using IoT concepts.

Yes, it seems that robotics is ahead of the curve when it comes to the IoT.

Image: Mit.edu

Image: Mit.edu

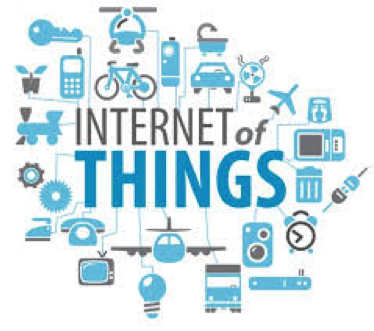

What is the Internet of Things?

The IoT is not so easy to define, but basically it is all about connectivity between devices. Every piece of technology should be able to talk to every other piece of technology to produce some sort of decentralized super-system.

Let's take as an example the idea of a Smart Home, which is one of the core application areas for IoT. The basic idea would be that your TV could communicate with your mobile phone, which could communicate with your toaster, your fridge, your watch, your heating system, your coffee maker… every gadget, basically, could talk to each other.

What is the point of all this? Well, think about how things are actually connected at the moment. Thanks to cloud based services, social networks and mobile phone apps, we can see a little bit what the IoT looks like already. Your mobile phone downloads your emails, which are also available on your computer. If you go for a run or cycle with a GPS wristwatch then it will track your journey and also upload the run automatically when you enter a WiFi network. You can then sit down in front of a Web enabled television and look at the analyzed data from your journey.

Basically, the point of the IoT is to be able to monitor and interact with your personal data in a pervasive way (i.e. it's everywhere). Here's a nice little video demonstrating an application of the IoT for a car manufacturer. The idea is that the mass interconnection of devices and sensors will make your life a little bit easier and also add functionality that we have never even dreamed of yet - just think how many interesting and surprising applications have grown out of the simple combination of a GPS chip and 4G network.

Although the IoT might sometimes seem to be a huge new thing, in fact it is quite a logical progression of the technology we have today.

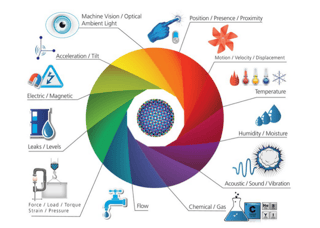

Why is the Internet of Things Important for Industrial Robotics?

IoT is quite easy to understand in the context of day-to-day life. But, how is it useful for industrial robotics?

To answer this, let's look at how two big robotics companies have already implemented IoT concepts into their systems:

ABB

In 2015, ABB placed itself at the heart of IoT technologies in industrial robotics by becoming part of the Industrial Internet Consortium. Although IoT might seem new, ABB announced earlier this year that their IoTSP (Internet of Things, Services and People) strategy has been underway for the last 10 years. They have been finding ways to integrate all of the sensors and devices on a manufacturing shop floor to improve all areas of their operations, including: reducing the downtime of robots, improving the reliability of systems and optimizing processes.

As they describe in this video, there are great benefits when every robot is able to store and analyze its own usage data, then is able to communicate that data smartly to other connected devices. For example, it means that ABB doesn't have to schedule the maintenance of a robot by a simple, old-fashioned "after 10,000 hours of uptime”, which might be overly conservative. Instead, the robot itself can monitor its own actual usage and report on its performance. ABB can schedule maintenance of the robot at the perfect time to avoid interfering with its operations, by looking at when the robot is actually used most. It can also mean that problems are caught before they have even become problems.

KUKA

In 2014, KUKA integrated with Microsoft's Azure IoT platform to create a "connected factory" of 60,000 devices and 259 robots. This 24 hour automated factory is able to manufacture automobiles very flexibly thanks to the IoT approach. This application shows that IoT concepts can be well and truly integrated into industrial robotics. We can expect to see many more examples like this turning up in the coming years.

Image: Mit.edu

Image: Mit.edu

Is There a Common Protocol for the Internet of Things?

One of the big issues which you might imagine is how to decide on a common protocol. In order for everything to be able to communicate, the devices must be "speaking the same language."

In the consumer world, for the moment at least, there are already four big competing protocols - Qualcomm's AllJoyn, Intel's IoTivity, Apple's HomeKit and Google's Brillo. There are also a load of smaller platforms. Although these consumer protocols might be used for home robots, industrial robotics is going to need a slightly different protocol. Security will be paramount, not least because a successful hack could do real damage if it gained access to a robot. There are a few potential options for an Industrial Internet of Things (IIoT), including the Connext DDS protocol from RTI and Predix from General Electric.

You might think that it's going to be difficult to decide on a standard protocol. However, one of the proposed strengths of the IoT approach is that it, supposedly, does not rely on a standard protocol. It looks like the IoT might not end up with those long, heated discussions that we've had in the field of robotics research before we finally ended up with ROS as an (almost) universal platform. Instead, the IoT is all about the communication paradigm between many devices regardless of the specific protocols used.

So, for example, all of the robots in my factory might communicate using one platform, while all the robots in your factory might use a different platform. Even though my robots couldn't communicate directly with your robots we would both still be using the IoT approach. Even so, I can foresee that some sort of linking protocol will become necessary in the future; however, we shall just have to wait and see.

For an in-depth look at how to prepare for the Industrial Internet of Things see this white paper from Robotics Tomorrow.

Do you think the Internet of Things is all hype, or is it a game changing new technology? Have you used IoT approaches with your own robots? What issues can you foresee coming up with IoT platforms? Tell us in the comments below or join the discussion on LinkedIn, Twitter or Facebook.

Leave a comment