Robotiq Releases the 2-Finger 140 Adaptive Robot Gripper

Posted on Sep 17, 2015 in Robot Grippers

3 min read time

Using adaptive Grippers make life easier for robot users that require a great flexibility for a high mix of parts. With applications such as machine tending and consumer goods handling, the variety of parts is often impressive for a single workstation. This is why we are releasing the 2-Finger 140 Adaptive Gripper. A robot Gripper for lighter, larger parts.

The new gripper comes with 140 mm programmable stroke fingers and a 2 kg payload. Its built-in advanced control allows you to detect that a part has been picked, pick soft parts without crushing them or pick deformable parts while maintaining a safe grip as the robot is moving.

“We have important customers who need a robot to handle thousands of different objects every day for their logistic operations. They were involved in the product design process and some of them have already deployed the Gripper to successfully automate flexible handling tasks.” explains Robotiq’s CEO, Samuel Bouchard.

Why a wider stroke?

Since Robotiq's goal is to provide its users with a lot of flexibility, we thought it would be great if users could enjoy a larger grip for objects from 0 to 140 mm (0 to 5.5 inches). You can then grasp wider objects, objects with bigger diameters and you are not limited to grasping the object by a single feature. Since our Gripper is mostly used on Universal Robots, a flexible easy to program platform, it is logical to have a Gripper that can expand the flexibility of this platform for achieving different applications; though, of course, the Gripper will fit many other platforms, as well.

The Gripper is designed around applications such as machine tending, electronic parts handling and consumer goods handling. All applications that requires a lot of flexibility due to their high-mix of parts.

What does a larger stroke mean?

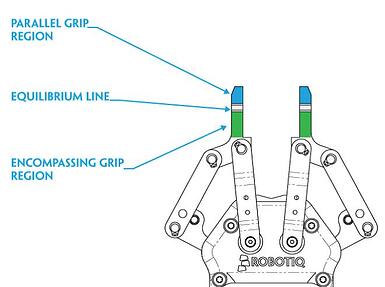

There are 2 important differences involved with having a larger stroke. First, your equilibrium point is not in the same place and second, the Gripper payload is lowered.

In fact, the equilibrium point is the determining point on the distal phalanx where the adaptive finger performs either a parallel grip or an encompassing grip. This point changes depending on your opening, but it also changes depending on the height of the fingers. In this case, the fingers are longer since the stroke is wider. This means that the equilibrium point changes from 25 mm to 45 mm with a reference to the pivot of the phalanx. In other words the equilibrium point is 20 mm higher when using a 2-Finger 140 Adaptive Gripper. What I am trying to underscore here is that the behavior of the Gripper is quite different and that objects will not be treated the same way with an 85 mm stroke gripper and 140 mm stroke gripper.

Since the fingers are longer, the distance between the center of mass for the object and the base of the Gripper is also longer. This transfers more force to the gripping mechanism which automatically means that the 140 mm stroke Gripper will carry lower loads. According to our in-house testing, we have establish that a 2.5 kg payload and a grip force range of 10 to 100 N can be consistently achieved.

As the main parts of the Gripper remain the same, the casing can easily be fitted on a Universal Robots with the 2-Finger kit for Universal Robots as is done with the 2F85. You can then use your Gripper with the same embedded Robotiq interface in the UR controller. So, the same programming code can be used to run your Gripper autonomously and with greater flexibility.

.jpg)

Leave a comment