Calculate a Pressure Applied by a Robot

Posted on Sep 20, 2016 in Safety

1 min read time

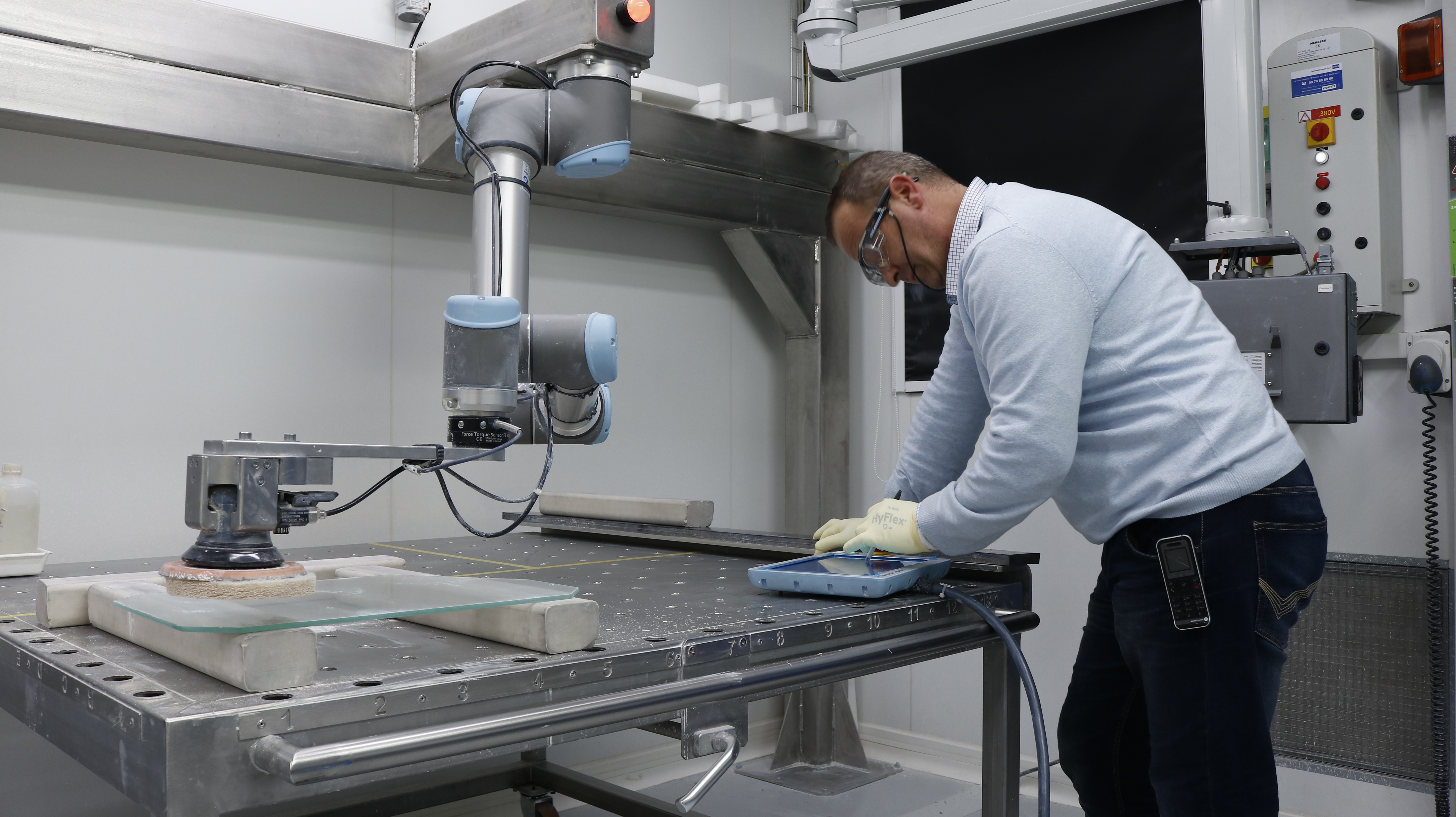

In a robotic risk assessment process your goal is to predict (or at least try to predict) the possible impact that can occur in the use of a robot. In the case of a collaborative robot, you want to consider the potential impact that can occur when the robot is working alongside the worker. As the ISO/TS 15066 has rated and ranked allowable forces and pressure for different body parts, it is now easier to determine if the impact will be harmful or not for the human. Before doing so you need to determine a couple of parameters. The following video explains how an impact pressure is calculated.

Pressure is simply a force spreaded on a surface. As you probably figured, the larger the area the less the pressure. If the force is applied on the tip of a needle, the pressure will be high and will probably overshoot the collaborative robot standard recommendations. On the other hand, if the force is applied on a large surface, the pressure will be lower and will allow a safe collaboration between the robot and the user.

There is also the material component that has to be considered. In fact when looking at an impact in a dynamic way, the deceleration will depend on the robot speed and time to react but will also depend on the robot or human material. This is why the ISO/TS 15066 considers different pain levels for different body parts. In fact, a hand will be more fragile than a femur for example.

That being said, this factor is not considered in the calculation since the threshold already has been adjusted.

To have more details on the risk assessment process for collaborative robots, we recommend to take a look at the following links.

Risk Assessment, an Introduction

Leave a comment