How Robots Help the Consumer Goods Industry Adapt

Can small companies keep up with the new, demanding consumer? Here's how robotics can help!

Consumer goods represent a huge industry, with some saying that it has been keeping the US economy afloat over the last couple of years. Consumer goods are any products which will be bought directly by the end user, including food, clothing, perfume, furniture, etc. They are distinct from "industrial goods" such as machinery and materials, and "capital goods" which are sold to other businesses for later processing.

Automation has been making its way into the consumer goods industry for some years now, particularly for packaging applications. Robotics is one of the key disruptive technologies that is turning the industry on its head. According to RIA, the food and consumer goods industry broke a record last year when it increased its robot orders by 32%.

The Consumer Is Changing

Over the last decade or so, consumers have changed the way that they buy products. According to the World Economic Forum, a new empowered consumer is pushing the industry to operate differently. They demand a much higher level of control over their buying journey and want customized products with more engagement from producers.

The modern consumer now expects many producers and retailers to create an entire experience instead of just providing products. They want to get involved with producers by contributing to the companies themselves in some way (e.g. via crowdfunding), personalizing their own products or interacting with the companies via social media.

Some of these new demands require a fundamental shift in the way businesses build their products. Increased customization means that manufacturing processes need to be more flexible. More interaction with customers means that small businesses have less time to spend manufacturing their product. Robots are one way to move workers away from non-value-added tasks and onto tasks which fulfill the customer's increased expectations.

This year, the World Economic Forum identified eight technologies which are expected to disrupt the retail and consumer packaged goods industry, some of which we have covered before:

- The Internet of Things

- Autonomous vehicles and drones

- AI and machine learning

- Robotics

- Digital traceability

- 3D printing

- Augmented reality

- Blockchain

Robotics Are Used in the Entire Supply Chain

Robotics can be used in three stages of the consumer goods supply chain, from manufacture to retail.

Robots in Manufacture

Robots can reduce the cost of manufacture and allow some processes to be run around the clock. This makes it feasible for smaller manufacturers to produce higher volumes of product to continue to grow the business without compromising quality. Collaborative robots provide an added benefit that they can be easily reprogrammed to new product designs, meaning that they fit perfectly with the trend towards product personalization.

Robots in Distribution

Logistics and warehousing have seen an increasing trend towards automation in recent years. Consumers are demanding more customized orders with shorter lead times. Traditional logistics solutions will increasingly struggle to meet these requirements so robots are starting to relieve some of the pressure. Collaborative robots are often used in packaging and palletizing applications, while robotic ground vehicles are used for autonomous warehousing.

Robots in Retail

At the customer-facing end of the industry, consumers are demanding more engagement with store staff. As they can easily buy a product online, people come to bricks-and-mortar shops to interact with a real person. This gives store staff less time to deal with stock. Robots are one way to free up staff and allow them to enhance the customer experience. So far, robotics at this stage is less established than at the other stages in the supply chain. However, robotic assistants seem likely in the near future — like Lowe's NAVii robot which helps shoppers locate particular products in the store.

How Can Small Businesses Keep Up?

It's easy to see how large providers of consumer goods, like Amazon, can keep up with the consumer trends. But, how can small manufacturers compete?

Companies who provide bespoke or artisan consumer goods could find it increasingly difficult to keep up with consumer demands whilst preserving the quality of their products. Robots can help to relieve the pressure on manufacturers, allowing them to engage more with their customers and work on new product design.

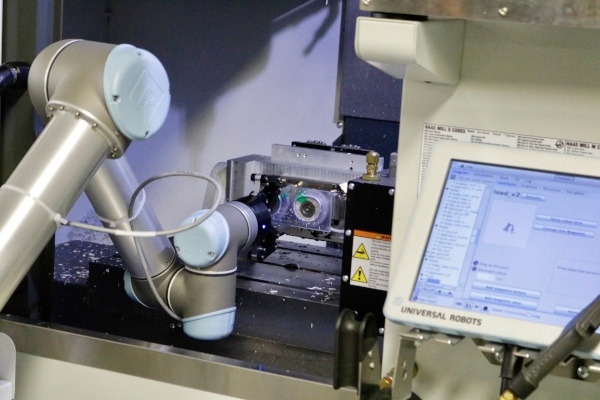

Lowercase is a New York-based start-up who design and manufacture artisan eyewear. They are one of the few eyewear manufacturers who operate entirely in the USA. We recently reported on them on the Robotiq blog and created a case study about them which you can download here.

The problem Lowercase faced was that their CNC machine was taking lot of their time. The machining process was labor intensive, with each pair of eyeglasses being removed and replaced twice in the machine. The task was repetitive and high volume. For a two-person team, it was starting to affect their ability to focus on other parts of the business.

As we showed in the case study, they invested in a Universal Robot to tend the CNC machine. The integrator taught them to program the robot, allowing them to easily adapt its operation to changes in their eyeglass design. This was vital as they had 17 different styles of eyeglass and needed to reprogram the robot on-the-fly.

Lowercase is a perfect example of a small consumer goods who are using robotics to help them keep up with the changing needs of customers. By incorporating a collaborative robot at the manufacturing stage of the supply chain, they are able to spend more time developing new designs and interacting with their customers.

How are your customer demands changing? How could use use robotics to keep up with those demands? Which stage of the supply chain causes you most difficulty? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

Leave a comment