How Many Fingers Do You Really Need for a Robot?

Posted on Sep 04, 2015 in Robot Grippers

6 min read time

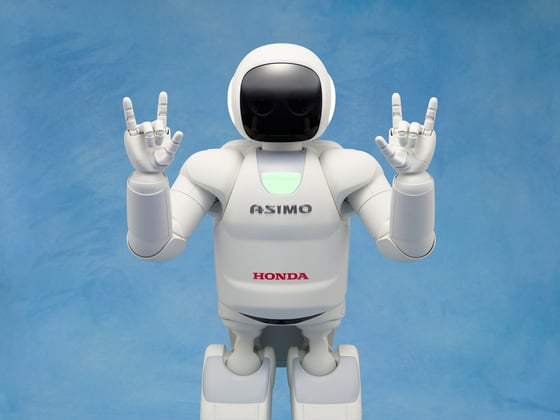

Why do we humans have 5 fingers on each hand? It’s a question which you probably rarely think about. But, as roboticists, it’s a vitally important one to ask as we decide how many fingers to give a robot. Needlessly adding extra fingers increases the cost of a robotic system, reduces efficiency and complicates the control unnecessarily. However, some roboticists believe that robot hands should be anthropomorphic (human-like) to complete tasks as well as a human would. Should robotic hands have 5 fingers just because our hands do? In this post we explore how many fingers are really necessary and which factors are most important when choosing how many fingers to give a robot hand.

Why Do We Have 5 Fingers On Each Hand?

As roboticists, we often have to decide how many fingers to give a robot. It’s sometimes helpful, and quite fashionable (thanks to research into bio-inspired robotics) to look to nature for answers. With that in mind, some robotic researchers believe that an anthropomorphic, five-fingered hand is optimal for a robot to match human performance.

But why do humans have five fingers in the first place?

To answer this, we must look to the animal kingdom. It turns out that almost all animals have five digits or fewer on their hands and feet. This can be traced back to an evolutionary split around 340 million years ago, when animals moved from the sea to the land. Around this time, evolution divided animals into two groups: amphibians (frogs, salamanders, etc) and amniotes (mammals, birds and reptiles).

Before this division, biologists have found evidence of animals with up to 8 digits, attached to limbs that looked more like paddles than legs. Multiple digits are useful for swimming as they allow animals to push through the water effectively (imagine the spines of a fish fin as digits and you’ll see what I mean). However, on land these limbs had to evolve to walk on many different surfaces, subjected to much more demanding forces. The many thin “fingers” of underwater animals were replaced by a set of fewer, stronger fingers with more rotation relative to the animal’s leg to stand the stresses of walking.

As they evolved, animals continued to lose digits. Many settled on five, four or three digits. As with engineering, the axiom of “simpler is better” has also been true for the evolution of hands. Biologists note that, although it is common for evolution to reduce the number of fingers, it is extremely uncommon for the number to increase. In rare cases where animals have “re-evolved” a sixth finger, such as moles or pandas, the extra finger has come from a re-purposed wrist bone.

Neurologist Frank Wilson, a leading authority on the hand-brain relationship, is reported as saying that the exact number of fingers is probably not so important. Six fingers are too many, he says, and fewer fingers usually seem to be better. There is no good evidence that five fingers are preferable to four.

Clearly the advantage of simplification outweighs any advantages that evolving extra digits might give, at least in the natural world.

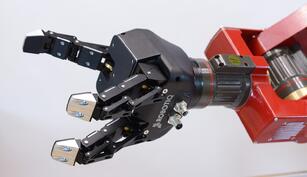

What is the Minimum Number of Fingers a Robot Needs?

The simple answer to this question is: As many as your task requires and no more.

Simplifying the number of fingers is as important in robotics as it is in the natural world, if not more so as each unnecessary digit adds cost and control complexity.

We have already covered in a past blog post how to choose the right type of robotic gripper for your application. However, when it comes to choosing the number of fingers, there are a few key factors to take into consideration:

The Bare Minimum: 2 Points of Contact

Unless your robot is only going to be pressing a button all day, it is fair to say that most robotic hands will require at least two points of contact with an object. The exceptions to this would be a vacuum cup or magnet, which both have one point of contact, but we can’t really define them as hands. Points of contact may be provided by multiple digits or, in some special cases, spread over a single digit like tentacles that we’ll discuss in a moment.

The Power of 3: When to Add Another Finger

If you have ever tried to pick up a marble with a pair of chopsticks (and who hasn’t?) you will appreciate how tricky it is to hold a spherical object with only two points of contact. Due to the small surface area on the tip of the chopstick, you need to apply a high force to keep the sphere from dropping. Lack of a third point of contact means such a grasp is usually unstable.

Three or more fingers are required when you want to control the orientation of the object the robot is holding (known as in-hand manipulation) or if you need to perform precision holds on a spherical object.

Increasing the surface area of contact points is one way to make a two-fingered grasps more stable. Another way is to make the contact point deformable, like our own fingertips. However, neither of these solutions allows you to change the orientation of the object in-hand. For that, you need to add a third finger.

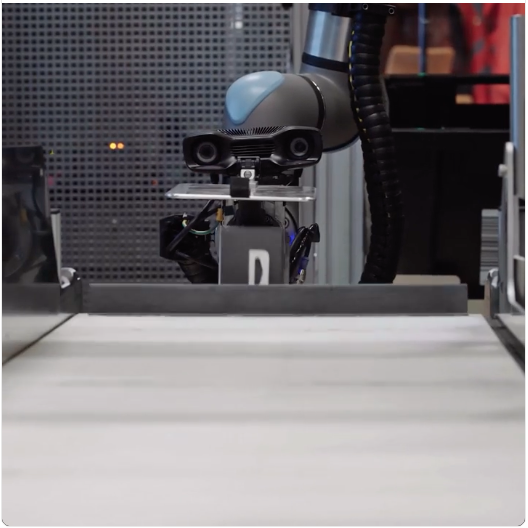

A Case for More Points of Contact: Spreading the Load

One of the key considerations when choosing a robotic hand, especially for food manufacturing, is how delicate are the objects to be handled? Adding more points of contact allows you to reduce the contact force at each point, by increasing the surface area on which friction is acting. For the same reason, more points of contact allows you to perform stronger ‘power grasps’.

However, adding more points of contact doesn’t necessarily require adding more fingers. You can also have several points of contact on the same digit. A robotic tentacle, for example, can be thought of as a one-fingered robot with multiple points of contact. The startup company Soft Robotics recently announced their tentacled robot for handling soft objects like fruits and vegetables.

A Quick Tip for Choosing the Number of Fingers for Your Robot

As designers, we often get caught up trying to analyze the optimal design of our robots on paper or in simulations. One quick tip to decide how many fingers are needed for your robot (before starting to simulate) is to walk through the task yourself using two, three, four or five fingers.

For example, if you were analyzing an assembly task you would:

- Take the parts to be assembled (or use scale models of the parts if the task is too big or small)

- Try to assemble them on a table top only using two fingers

- Then assemble them again using three fingers, up to the maximum number of fingers available for your manipulator.

This quick exercise can save many design headaches later on as it means you start the design phase with an intuitive understanding of the task requirements from the perspective of gripping.

Have you had any success in reducing the number of fingers for your robot? How many fingers have you found to be effective in the tasks you perform? What process do you use when choosing or designing a robotic hand? Tell us in the comments below.

Related Articles:

HOW TO CHOOSE THE RIGHT END EFFECTOR ?

CHOOSING THE RIGHT ROBOT GRIPPER FOR YOUR ENVIRONMENT

.jpg)

Leave a comment