Heavy lifting gone light: How RAIN boosted throughput with a compact cobot palletizer

Posted on Nov 18, 2025 in Palletizing

2 min read time

RAIN Pure Mountain Spring Water runs a fast-moving beverage operation. Multiple SKUs, tight floor space, and rising demand put pressure on their end-of-line team. The biggest bottleneck was manual palletizing. Operators were lifting 30-lb cases at six per minute, often reaching 100,000 lbs per shift. Throughput depended on human endurance, and the strain was adding up.

When manual palletizing holds the line back

RAIN faced familiar challenges for mid-sized beverage manufacturers:

- Labor-intensive tasks: Two operators stacked heavy corrugated cases all shift long.

- SKU complexity: More product variations increased the risk of stacking and labeling mistakes.

- Limited space: Traditional palletizing equipment was too large for their facility.

Even with engineering expertise in-house, building a custom palletizer would have meant long lead times and higher risk.

A compact, ready-to-run fix

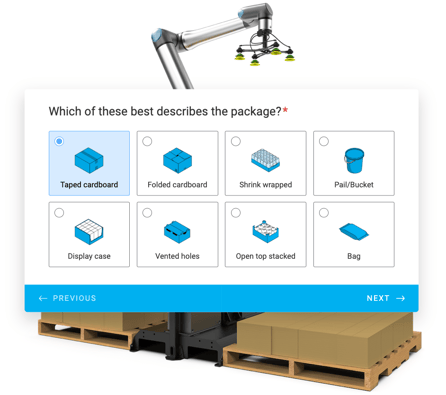

RAIN selected the Robotiq PE20 Lean Palletizer, powered by a collaborative robot from Universal Robots. The system delivered the speed and reliability they needed—without major layout changes.

Key advantages for RAIN:

- Small footprint that fit their existing line

- Integrated safety scanner that reduced guarding requirements

- Fast deployment with minimal downtime

- Easy programming, even without robotics experience

Founder Mark Majkrzak summed it up simply:

“This solution improves throughput, operator health and safety, gross production and labor utilization. All without anyone losing their job.”

Turning heavy lifting into high-value work

Automation didn’t replace RAIN’s team; it elevated them.

The two operators previously dedicated to palletizing now hold forklift certifications and support higher-value areas of the plant.

Meanwhile, the PE20 runs consistently and keeps pace with production. RAIN got:

- Immediate throughput gains

- A safer, more ergonomic workflow

- A faster-than-expected ROI

What this means for beverage manufacturers

RAIN’s experience reflects a pattern across the Food & Beverage industry. Compact cobot palletizers remove the most physically demanding end-of-line task. They scale with SKU changes. They fit where traditional systems can’t. And they deliver results in weeks, not months.

If you want to see whether palletizing automation makes sense for your facility, start here.

Try the Palletizing Fit Tool — a quick, interactive way to see if Lean Palletizing is the right match for your line.

Want more stories from real factories like yours?

Follow Robotiq on LinkedIn and join over 75,000 manufacturers seeing how automation keeps people safe, and production running strong.

-2.png)

-1.jpg)

Leave a comment