Lessons from 300+ palletizing projects in 2025

Posted on Feb 02, 2026 in Palletizing

5 min read time

After more than 300 palletizing deployments in 2025—and over 900 Lean Palletizing units now running in production—we saw a clear pattern emerge.

The manufacturers who succeeded didn’t have perfect data, unlimited budgets, or robotics teams on standby. What they had was clarity: on their pain, their priorities, and their willingness to start.

Here’s what 2025 taught us about palletizing automation and what it means if you’re considering your first move.

And if you prefer watching over reading, you can get these insights along with video case studies from SC Johnson, Coca-Cola, and Korea Filter Engineering in our webinar replay.

1. Labor challenges aren’t temporary. They’re structural.

By 2025, labor shortages stopped being a risk and became an operating condition.

Across food, beverage, and consumer goods, manufacturers told us the same story:

- Chronic difficulty staffing palletizing role

- High turnover on repetitive end-of-line tasks

- Growing reliance on overtime or temporary labor

The lesson was blunt: cobot palletizing protects production continuity. It doesn’t solve hiring—but it removes your most fragile dependency from the equation.

2. Safety moves projects faster than productivity ever will

Many manufacturers assume automation decisions are driven by throughput. In reality, safety unlocked approvals faster than productivity gains.

Projects moved quickest when:

-

Ergonomic risks were clearly documented

-

HSE and HR were involved early

-

Palletizing was framed as a long-term safety investment

In 2025, the fastest projects didn’t start with cycle times. They started with people.

3. ROI works best when it’s framed as cost avoidance

Winning projects didn’t “prove ROI later.” They quantified it upfront.

Successful teams came prepared with:

- Labor cost per shift

- Annual cost of staffing a palletizing station

- Overtime, turnover, and injury-related costs

Projects that stalled often lacked a financial baseline or a clear owner. The takeaway: ROI framed as cost avoidance succeeds, especially with operations and finance stakeholders.

4. One line beats a factory-wide plan

Ambition killed more projects than budget.

Manufacturers who succeeded started with:

- One line

- One product family

- One clear problem to solve

They deployed, learned, stabilized—and only then scaled. Waiting for the “perfect” factory-wide solution consistently delayed progress. In 2025, momentum beat perfection every time.

5. Ownership matters more than technology

Some stalled projects had the right robot, the right application, and the right partner. What they didn’t have was ownership.

Successful palletizing projects had:

- A named sponsor

- A clear decision-maker

- A timeline tied to real operational pressure

Automation treated as a “nice-to-have” rarely moved forward. Decisions must be owned to move.

6. Most palletizing applications are already cobot-ready

One of the biggest surprises from 2025: how many manufacturers already qualified for cobot palletizing.

If your application looks like this:

- Cases between 1–35 kg (1–77 lbs)

- Standard pallets (48x40 or Euro)

- Stable end-of-line flow

- Hard-to-staff palletizing role

You’re likely lower risk than you think. For many plants, the barrier wasn’t feasibility—it was perception.

7. End-of-line is where pain concentrates

Palletizing consistently delivered the fastest relief because:

- It’s hardest to staff

- It carries high ergonomic risk

- It’s isolated from upstream processes

Compared to automating earlier production steps, end-of-line palletizing minimized disruption while delivering immediate operational impact.

8. Waiting for growth is a losing strategy

A common hesitation we heard: “We’ll automate when volumes increase.”

In reality, labor constraints hit before growth does. Manufacturers who automated early used palletizing to:

- Enable growth

- Absorb demand spikes

- Avoid future bottlenecks

Those who waited often found themselves reacting under pressure. In 2025, automation worked best as a growth enabler, not a last resort.

9. Flexibility beats peak speed

Manufacturers routinely overestimated how fast they needed to palletize.

What actually mattered:

- Reliable uptime

- Easy changeovers

- Operators who felt confident running the system

Peak speed looked good on paper. Reliable flexibility won on the floor.

10. Cobot palletizing works best as an operational tool

The most successful manufacturers stopped treating palletizing as a one-off automation project.

Instead, they treated cobots like:

- Standard production equipment

- A safety and workforce stability asset

- A long-term part of their operating model

When palletizing felt complex and risky, adoption suffered. When it felt familiar and usable, it stuck.

Bonus lessons that changed minds

Integration fear is bigger than the real integration effort.

Most deployments happened in 1–3 days, not weeks, with minimal upstream changes and lighter IT involvement than expected.

Downtime risk matters more than capital cost.

Executives focused less on CapEx and more on missed shipments, overtime, and exposure when labor didn’t show up.

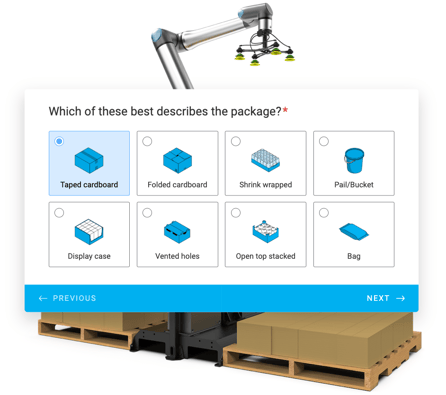

Ease of use determines long-term success.

Operators—not engineers—run palletizers every day. Simple interfaces and fast training consistently outperformed advanced features.

The common starting point

Manufacturers who moved forward typically began with:

- One line, one product family

- A simple ROI estimate (labor + safety)

- A low-risk feasibility check

- Clear ownership and a timeline

The lesson from 2025 is clear: palletizing automation doesn’t need to be complex to be effective. It needs to be grounded in real operational pain—and designed for the people who run it every day.

Is Lean Palletizing the right fit for your production line?

Not every line has the same requirements. Payload, cycle time, SKU mix, and available space all matter.

Use Robotiq's Palletizing Fit Tool to quickly assess whether cobot palletizing makes sense for your operation and what a realistic deployment could look like for your facility.

-2.png)

-1.jpg)

Leave a comment