Eckerts Distillery automates palletizing safely and efficiently with Robotiq Lean Palletizing

Posted on Dec 11, 2025 in Palletizing

3 min read time

Eckerts Wacholder Brennerei GmbH is a German distillery that blends long-standing craftsmanship with modern production methods. To improve packaging efficiency, the company implemented Robotiq Lean Palletizing. This automation project increased throughput, improved safety, and reduced the manual workload—all without disrupting the distillery’s traditional processes.

The challenge: Heavy cartons, weak boxes, and limited space

Eckerts produces and ships a wide range of spirits. The end-of-line palletizing process created several bottlenecks:

- Heavy cartons (up to 8 kg each) slowed down manual handling.

- Structurally weak boxes required gentle, consistent placement.

- A compact workshop made it difficult to install fully enclosed systems.

- Safety concerns arose because employees needed to work close to the robot.

- Training time for new technology had to remain minimal to avoid disruptions.

The team wanted automation that improved efficiency while protecting both product quality and employee well-being.

Why Eckerts selected Robotiq

To validate the solution, Eckerts sent its heaviest cartons to Robotiq’s Lyon office. The palletizer successfully handled every box type, demonstrating its capability before installation.

Key attributes that supported the decision:

- Open, enclosure-free layout that fit the distillery’s limited floor space.

- Integrated safety features that stop the robot automatically when people approach.

- Fast onboarding, allowing employees to use the system confidently after one day of training.

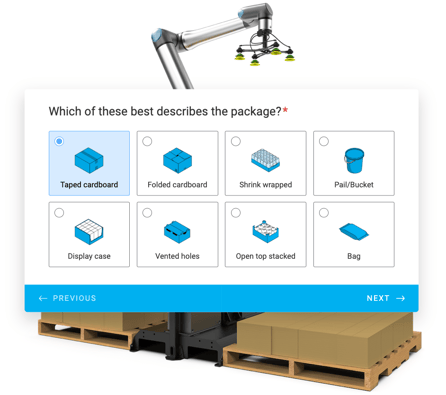

- Compatibility with 15 different carton types, reducing changeover effort.

“This solution is one of the best things we have bought in recent years. The system has been running flawlessly from day one.”

- Production Manager Andreas Klemp

The solution: Robotiq Lean Palletizing

Robotiq Lean Palletizing provided the following capabilities:

- High throughput, supporting up to 500 cartons per hour.

- Precise handling, ideal for fragile or weaker cardboard structures.

- Safe human-robot interaction, suited for small production spaces.

- User-friendly software that simplifies setup and operation.

The system’s design allowed Eckerts to automate palletizing while preserving the workflow of a traditional distillery environment.

Results: Efficiency, safety, and faster operations

After implementing the Robotiq solution, Eckerts observed several improvements:

1. Increased efficiency

The palletizer handled heavy loads consistently, reducing manual lifting and improving overall throughput.

2. Lower labor costs

Operators could shift from repetitive tasks to higher-value responsibilities in production.

3. Safer working conditions

Built-in safety features maintained a secure environment, even within a compact workspace.

4. Rapid employee adoption

Training required only one day, reducing downtime and enabling immediate use.

The impact: Tradition supported by modern automation

Eckerts’ experience demonstrates how automation can integrate seamlessly into a heritage-focused industry. Robotiq Lean Palletizing helped the distillery:

- Maintain product quality

- Reduce physical strain

- Improve production stability

- Support long-term operational sustainability

Automation became a way to protect craftsmanship, not replace it.

Explore Lean Palletizing for yourself

Manufacturers facing heavy loads, mixed packaging, or workforce constraints can benefit from the same reliable and safe automation system used at Eckerts.

If you want to see whether palletizing automation makes sense for your facility, start with the Palletizing Fit Tool — a quick, interactive way to see if Lean Palletizing is the right match for your line.

Want more stories from real factories like yours?

Follow Robotiq on LinkedIn and join over 75,000 manufacturers seeing how automation keeps people safe, and production running strong.

-2.png)

-1.jpg)

Leave a comment