Choosing the Best Task for a New Collaborative Robot

Posted on Nov 26, 2015 in Collaborative Robots

6 min read time

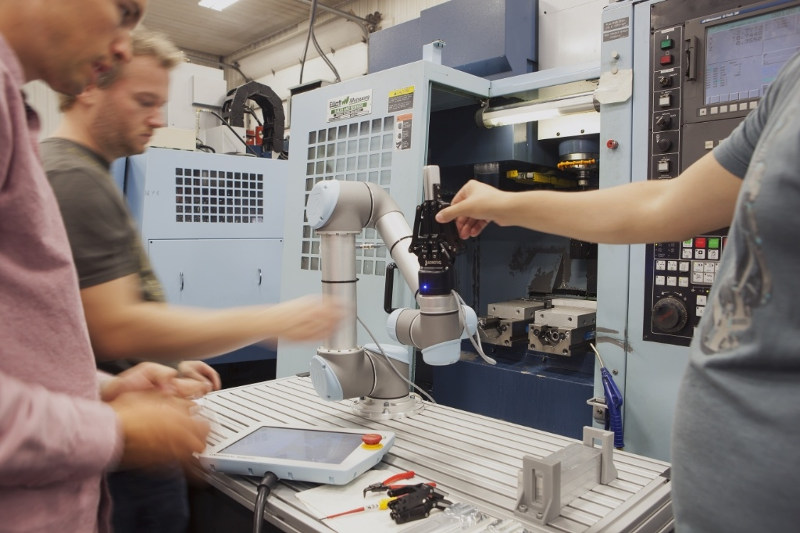

When starting out with collaborative robots it can be challenging to decide which tasks to assign them. Many operations have always been carried out by humans, so it might be difficult to imagine how we could do them any other way. In this post, we give some simple, but effective tips on how to get the most out of a cobot by choosing the right task.

If you are considering the introduction of a collaborative robot into your workflow, you might wonder which tasks you can give to it. Many of the demonstration videos that you can find online (including a few of our videos) might lead you to believe that collaborative robots are only able to perform very rough assembly tasks or pick and place applications. You might be thinking "But my tasks are more complicated than that! Is a collaborative robot really for me?"

Cobots can certainly perform more complicated tasks than just pick and place. However, often the first learning curve when using a new robot is being able to "think like a robot" - learning how to break down tasks so that the robot can do them. This is not a difficult skill to learn, but it requires you start with an open mind and a willingness to challenge your assumptions about the task.

Why Cobots and Humans Are Different

My personal robotic experience is mostly in telemanipulation research - controlling robotic arms through a communication link. You learn one thing very quickly when performing tasks through a telerobot - human arms and robotic arms are just different.

This may seem like an obvious truth, but it can cause lots of problems if you don't take time to consider what it actually means in practice. In order to complete a task effectively with a robot, you have to forget how you do the same task by hand and instead think how you could do it with a robot.

Different Kinematics

Kinematics are a huge part of the difference. Robotic arms and human  arms just have different kinematics. Although it's true that many collaborative robots now have 7 Degrees of Freedom (the same number as the human arm) they are not usually configured in the same way.

arms just have different kinematics. Although it's true that many collaborative robots now have 7 Degrees of Freedom (the same number as the human arm) they are not usually configured in the same way.

In practice, this means that you should get familiar with the limitations of your robot's kinematic chain. You might want to learn the basics of kinematics.

However, you don't even have to learn the mathematics to improve your working understanding of a robot's kinematics. One of the great advantages of most collaborative robots is that you can program them easily, often by moving them around by hand.

Getting familiar with the robot's capabilities simply requires that you approach the task like a robot, and that means getting hands-on.

Hands-On Kinematics

A Quick Exercise: Does your collaborative robot have only one arm? A quick and simple exercise is to stand in front of the task and try to complete it using only one of your own arms. If the robot only has a two or three fingered gripper, only use two or three of your fingers and move them in a similar way to the gripper. Depending on the complexity of the task, this will only take you a minute or two. But, it will teach you far more about the task than you would learn even after hours programming a simulator.

A Quick Exercise: Does your collaborative robot have only one arm? A quick and simple exercise is to stand in front of the task and try to complete it using only one of your own arms. If the robot only has a two or three fingered gripper, only use two or three of your fingers and move them in a similar way to the gripper. Depending on the complexity of the task, this will only take you a minute or two. But, it will teach you far more about the task than you would learn even after hours programming a simulator.

Many cobots allow you to physically move them around the workspace to program them. Use this feature to become really familiar with the robot's workspace. Try to move the robot to the limits of its workspace (and yes you can use both of your hands here). Explore all the different orientations from which you can approach the same point. Try holding the end effector steady in one place and move the elbow joint around to see how far it goes. Get to know the workspace really well.

Take a little quality time to explore every part of the robot's workspace and it will pay dividends later on.

Designing Tasks for Collaborative Robots

Since the 1970s, Design for Assembly has been a cornerstone topic in manufacturing. It is a process by which products are designed to be easily assembled. Part geometries are simplified, multiple parts are combined and the number of fixings is reduced to the bare minimum to make the product easier to assemble. The process of Design for Assembly has many added benefits, including reduced costs, improved quality, less inventory and quicker manufacturing.

Therefore, it's important to remember that designing for a collaborative robot is just another aspect of the process of Designing for Automatic Assembly. It's not necessary to immediately start redesigning all of your products so that the cobot can assemble them. However, the more you consider the capabilities of the robot in your future designs, the more effective it will be at performing those tasks.

As with every type of Design for Assembly, the process of designing for robotic assembly will also make assembly easier for humans. So, even if you decide to use the cobot for something else, the task itself will still be more efficient. You will also be in a good position if you later want to upscale to full automation, because your process will be more prepared for it.

Designing for Cobot Assembly

Design for Assembly can be split into two subtopics: Design for Automatic Assembly and Design for Manual Assembly. As collaborative robotics is still quite a new field, there is not yet an established process called "Design for Cobot Assembly”. The process will have similarities to both automatic and manual (human) assembly.

Cobots lie somewhere inbetween industrial robots and human workers. They have flexibility due to the ease of programming, but the tasks they can perform are restricted in a similar way to industrial robots. Complex tasks which require a lot of dexterity or Artificial Intelligence are possible, but they might not be the best choice for a collaborative robot, because it might take a long time to implement properly. Cobots are better suited to simpler tasks which are highly repeatable, but they are not restricted to them.

There are many working practices in Design for Assembly - far too many to cover in a single blog post like this one - but basically we can reduce the process to three simple words:

Simplify, Simplify, Simplify

Many different aspects make up a successful process or operation. As designers, we have control over a lot of them. For example, we could change the product, the process, the individual operations, the tools, and many other things to improve the operation overall. Just like any other engineering challenge, cobot operations will be successful if we always strive to make the task as simple as possible without impacting quality or any of the other important factors.

Collaborative robots are very flexible, but they are a tool like any other. If you have taken the time to really get to know the limits of the technology, you will be able to do a great many things with them.

What tasks would you like to perform with a collaborative robot? Which experiences have taught you the most about how to use robots effectively? What are your favorite Design for Assembly principles? Tell us in the comments below or join the discussion on LinkedIn, Twitter or Facebook.

Leave a comment