Top 5 Applications for Robotic Electric Grippers

Posted on Oct 15, 2014 in Robot Grippers

3 min read time

Electric servo grippers offer a different set of functionality than pneumatic grippers. They trade speed and force for flexibility. In fact having specifications such as programmable; stroke, force and speed can make your applications a lot easier. To figure out for which applications is this useful, read on.

1. Grippers for Assembly

For assembly tasks an electric gripper can be really useful. In fact, most assembly tasks are done at a single spot in the production line. This means the gripper that is positioned there must be flexible and be able to grasp different parts. There is absolutely no time for tool changing and this is why a flexible electric gripper should be used.

Also, grippers such as our 3-Finger Adaptive Gripper that have a programmable stroke can reduce the cycle time of the robot considerably. Especially since if you can set the stroke, the gripper doesn't need to run through its whole stroke before closing back on the object. The gripper can be set a little wider than the part and this can reduce the cycle time of the robot by reducing the gripper's motion.

Another interesting aspect of the electric gripper is that it can have embedded sensing. This means you can have direct feedback as to whether or not the part has been grasped by the gripper. This can determine the difference between a productive assembly and a badly integrated assembly.

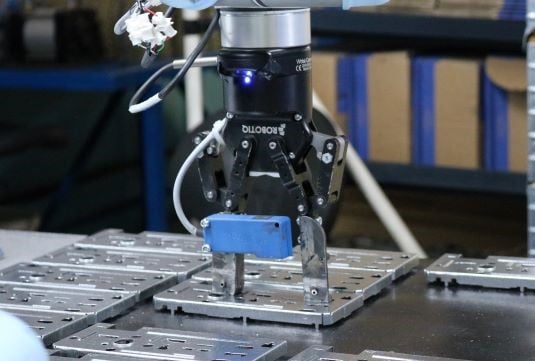

2. Grippers for Machine Tending

The advantage of using an electric gripper in machine tending applications is that some grippers can handle a lot of different shapes. In fact often the shape of the part will change from before and after the machining operation. This is why you should have a gripper that can grasp both the raw part and the finished part. Otherwise you might be stuck using a tool changer and this can be complicated as well as time consuming.

The advantage of using an electric gripper in machine tending applications is that some grippers can handle a lot of different shapes. In fact often the shape of the part will change from before and after the machining operation. This is why you should have a gripper that can grasp both the raw part and the finished part. Otherwise you might be stuck using a tool changer and this can be complicated as well as time consuming.

Another aspect that is often overlooked is your environment. In machining operations, there could be a lot of fluids involved. Since this can effect the functionality of your robot gripper, you have to choose a tool that can work well under your conditions. Irregardless of the type of gripper you choose, the IP rating should be known to make sure your gripper can handle your working environment.

3. Grippers for Clean Rooms

Laboratories or metrology rooms might require clean air environments. By using pneumatic grippers, the air can be contaminated. Some grippers are specifically clean room rated and are designed to be installed in these kinds of rooms. A good alternative to the pneumatic gripper might be an electric on-off gripper. This kind of gripper has the same functionality without the disadvantage of air contamination.

4. Grippers for Lab Automation

In the same way grippers that are used in laboratories might have to handle fragile parts such as tubes and trays. This means that the gripper probably requires programmable force, which can be done with an electric gripper. In fact, force is just a setting that can be changed in the gripper program to select the gripper grasping force which can be slight or firm depending on the part. In the case where the lab is using a pneumatic gripper, the force has to be set by adjusting the air pressure. However, if the pressure is not constant throughout the actionable time, then force could be higher or lower than necessary which could cause problems for the application.

5. Grippers for Mobile Robots

Pneumatic grippers always have to be fed by their air lines which makes it pretty hard to drive around with a hose as a tether. Electric grippers can run on batteries. Even if the electric grippers are more useful than a pneumatic gripper with certain kinds of applications, the Adaptive Grippers are even more efficient. In fact, since the Robotiq Grippers are equipped with self-locking fingers, there is no need to power the gripper while the part is grasped. This means, the gripper can be powered for its movement and then lock itself on the part and doesn't require any further energy input until it deposits the part. This can be a good choice for saving valuable energy.

Pneumatic grippers always have to be fed by their air lines which makes it pretty hard to drive around with a hose as a tether. Electric grippers can run on batteries. Even if the electric grippers are more useful than a pneumatic gripper with certain kinds of applications, the Adaptive Grippers are even more efficient. In fact, since the Robotiq Grippers are equipped with self-locking fingers, there is no need to power the gripper while the part is grasped. This means, the gripper can be powered for its movement and then lock itself on the part and doesn't require any further energy input until it deposits the part. This can be a good choice for saving valuable energy.

For more in-depth information on the advantages of electric servo grippers take a look at this ebook.

Leave a comment