DLR & KUKA: Grasp Planning & Control with the 3-Finger Robot Gripper

Posted on Sep 04, 2013 in Robot Grippers

3 min read time

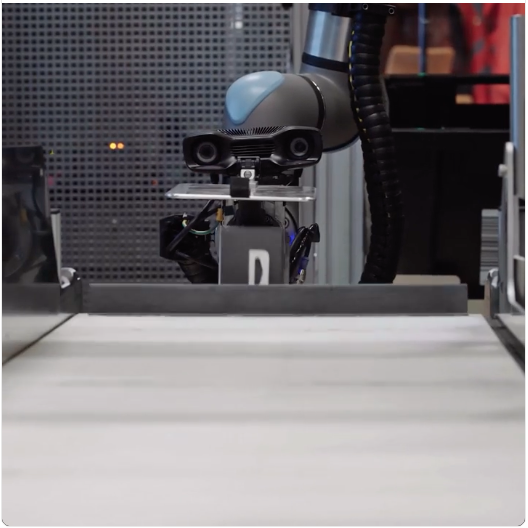

Many companies are interested by the adaptability of Robotiq’s Grippers. They want to experiment with it, and integrate it into their own product. Like the German Aerospace Center, DLR, which is working with KUKA to use the 3-Finger Adaptive Gripper as an end effector for the KUKA LWR arm to integrate grasp planning and control.

Partnership

The collaborative robot was first developed by the German Aerospace Center (DLR). The Light-Weight Robot (LWR) was originally designed to be used in space. However, with a technology transfer agreement, KUKA was allowed to use this technology and commercialize it for industrial purposes - read more on these new types of industrial robots here. Even if the LWR is now known as KUKA’s product, the DLR still works on the robot in collaboration with the company and different integrations have been made with Robotiq's product.

The collaborative robot was first developed by the German Aerospace Center (DLR). The Light-Weight Robot (LWR) was originally designed to be used in space. However, with a technology transfer agreement, KUKA was allowed to use this technology and commercialize it for industrial purposes - read more on these new types of industrial robots here. Even if the LWR is now known as KUKA’s product, the DLR still works on the robot in collaboration with the company and different integrations have been made with Robotiq's product.

About their work

The control framework developed by KUKA for the LWR enables great integration with Robotiq’s 3-Finger Adaptive Robot Gripper through a plugin. To complement the control framework of the LWR and our robotic hand, DLR uses a grasp planner based on the openrave simulation environment (http://openrave.org/).

First, a CAD model of the object is needed, then the geometrical shape of the object is analyzed. Based on the curvature and geometrical features, good locations are selected for potential grasping. Different grasp strategies can be implemented to allow the simulation to plan all the operating modes for the Robot Gripper such as Basic, Pinch, Wide or Scissor modes. With the simulation software, sequential closing of the fingers around the object allows for a simulation of the adaptability of the end effector. Then, when all the fingers are closed, the contact points are obtained and the quality of the grasp is evaluated. This method creates a grasp database for the known CAD model.

The same procedure is used for meshes of objects acquired from a vision system. However, the results obtained by a machine vision system can produce non-watertight meshes, but a good grasp can still be selected by avoiding regions where there is no information available.

To complete the simulation and prove that the grasp is a good one, a dynamic simulation using Bullet, as a physics engine, can produce real environmental effects such as gravity, friction forces and control strategies. This last step evaluates the robustness of the grip before it is tried with a real industrial robot.

These developments will help with further integration of Robotiq’s 3-Finger Robot Gripper and the KUKA LWR. This will also give some sort of intelligence to the Gripper, which will increase its adaptability, even though it is already one of the best.

.jpg)

Leave a comment