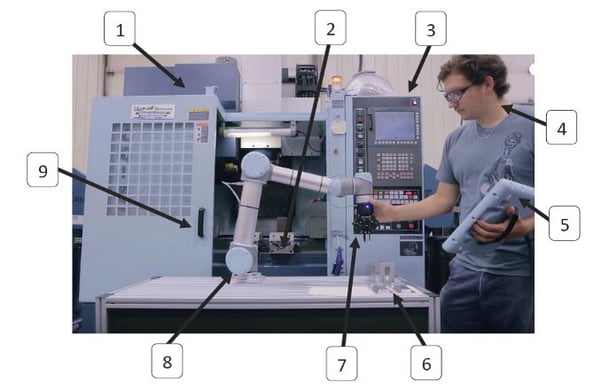

Anatomy of a Machine Tending Cell

Machine tending applications generally involve autonomously operating machines, like CNC machines. To fully understand what is involved in a machine tending cell, we break down its anatomy in this article.

According to the Oxford English dictionary, machine tending is "the action of supervising or tending a machine in operation, especially by performing routine checks and maintenance or ensuring the continuous supply of materials, as on a manufacturing production line; frequently with pejorative connotations of undemanding and tedious work."

To give you a first look at what is involved with a robotic machine tending cell, you may want to take a look at the video above. Following, we broke down the anatomy of a machine tending cell to get a better picture of what is involved.

- CNC Machine: CNC stands for Computer Numerical Control, a machine that can autonomously machine parts.

- Vice: Mechanical device that holds parts while they are being machined.

- Controller: The part of the machine that calculates and coordinates the motions of the machine.

- Operator: The worker who is operating the machine and will operate the robot.

- Teach Pendant: This device sends requests to the robot and runs programs on it.

- Parts: The part goes into the machine, generally one at a time, as raw material, and comes out as a machined part.

- Gripper: The machine tending cell will require a Gripper to grasp the raw material and load it into the machine. It will also be needed to collect the machined part after the transformation process.

- Robot: An articulated robotic arm can perform the tedious actions of loading and unloading parts for the operator, including opening and closing the CNC door.

- CNC Door: The door must be closed while the machine is running. For security this keeps metal debris confined within the CNC and prevents part projection.

Learn more about machine tending in our new Machine Tending Bundle, in which we explore how to improve your CNC machine production through the addition of a robot. You will also learn how to determine the baseline requirements for your application and how to build a return on investment assessment. Finally, you will have access to insiders’ discussions on machine tending implementation through our DoF community. Don't wait and get it now!

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment