7 Reasons to Automate Cabinet Door Sanding with a Cobot

Posted on Mar 12, 2020 in Collaborative Robots

5 min read time

Has sanding cabinet doors become a bottleneck in your business?

Can't afford a huge automatic sanding machine? Or even fit it in the workshop?

If you're a small cabinet maker, manual sanding can soon become your main task every day. It's boring, it's repetitive, and it's inefficient. But, investing big in a set of industrial sanding machines is just not feasible for the size of your operation.

So far, you've just "sucked it up" and kept doing your sanding operation manually with power tools. But, it's not giving you the flexibility and scalability of automated sanding. You really want to move to automation but you can't find the right method that will work for you. The traditional option (automatic sanding machines) just doesn't suit your needs right now.

Your manual sanding task has already started to severely limit the number of cabinet doors you can produce. You may even have reached your production limit.

Manual sanding cabinet doors takes forever

When you're producing hundreds of doors per week, sanding can start to become a real bottleneck. You just don't have enough capacity to handle all the orders that your shop is receiving. You may have even started to turn down new orders because your production can no longer match the demand.

Is it starting to feel like sanding is just the core part of your job?

Automated sanding machines are one option. Perhaps you have already considered them as a possible solution. These giant machines are generally great for low-mix, high-volume production, but they are costly and not well suited to smaller operations.

What are you supposed to do if your cabinet making operation is smaller?

Is there no way to get the benefits of automated sanding with the smaller price tag?

Scaling smaller sanding operations requires extra hands

The problem is that scaling a cabinet door sanding operation really requires the human touch. If your workload is too low to consider investing in high-volume automation, you need to start thinking about how you can add an extra pair of hands.

But, more hands mean more people and more people mean more salaries (that's if you can even find a good, qualified sander). This would be fine if your production figures were bigger, but at your current level it just doesn't make sense.

However, your "extra hands" don't necessarily need to be human hands. A newer solution is collaborative robotics. Cobots are the closest thing we've currently got to "cloning" yourself for sanding tasks.

7 reasons to automate cabinet door sanding with a cobot

Here are seven reasons that collaborative robots are the perfect option for smaller-scale cabinet door sanding:

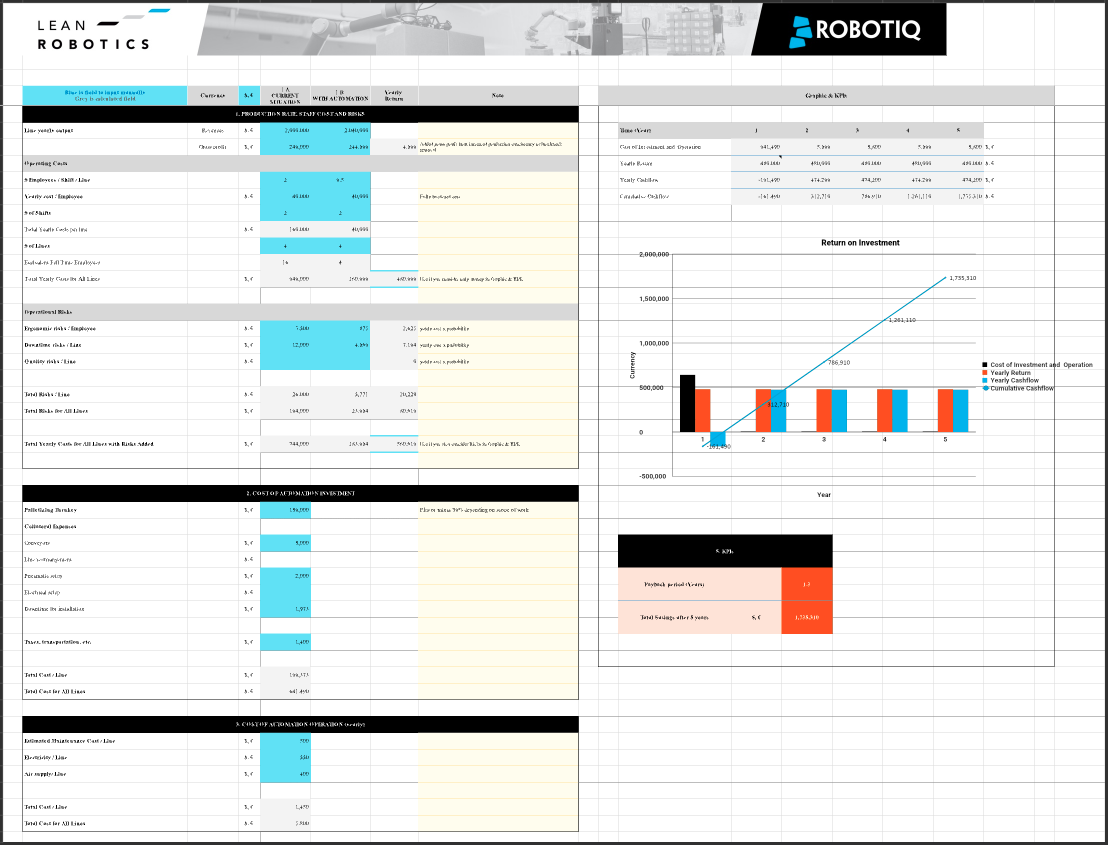

1. More cost-effective

Automatic sanding machines and traditional industrial robots are the main alternatives to cobot sanding. However, they can be quite costly both to purchase and to install/integrate.

Cobots are an affordable way to get started with sanding automation. They are easy to set up and you don't need much specialist knowledge to get them up and running.

2. Takes up much less space

Compared to other forms of automation, cobots are an impressively compact way of achieving cabinet door sanding. They require no more space than a human worker doing the same job.

An added benefit to cobots is that they can be easily moved around the workshop — if mounted on a movable table — so they don't need to hog your valuable floor space when not in use.

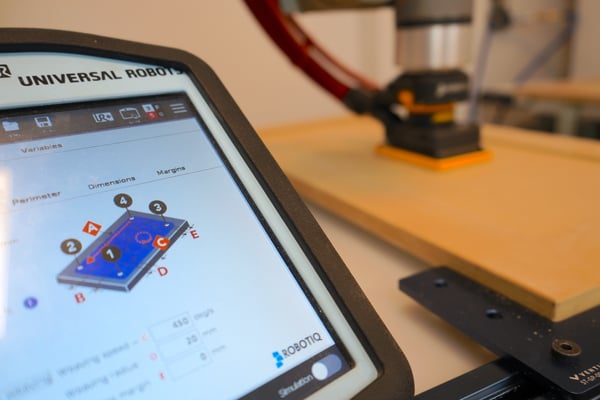

3. Easy to program

People sometimes worry that robots will be difficult to program. If we were talking about traditional industrial robots then that might be true. However, cobots are a whole different story.

You can program complex sanding trajectories with just a few points. With ActiveDrive you can even move the robot by hand to program the points.

Finishing Copilot's latest feature allows to teach variable trajectory according to the part's size

Finishing Copilot's latest feature allows to teach variable trajectory according to the part's size

4. Flexible sanding trajectories

Many sanding machines are very restricted in the shapes of surfaces that they can sand. For example, wide belt sanders can only sand flat surfaces. Although this is perfect for basic cabinet doors, it causes a problem when you want to use more complex shapes.

Cobot sanding is compatible with an impressive range of surface shapes. With just 4 waypoints you can program a flat surface. With 9 waypoints you can even program a spherical surface.

5. Can be used on other tasks

Probably the biggest problem of traditional automatic sanding machines is that they can only be used for sanding. If your production numbers were large enough that the machine was running all day, this would be great. However, when your numbers are lower it just ends up being a waste of resources.

Even though you have purchased your cobot for sanding, it isn't restricted to that task. Various members of our community use the same cobot for multiple tasks in their business.

6. Precise force control

One common problem with manual sanding is that inconsistent force produces an inconsistent surface finish. This problem is compounded when you have been sanding for many hours — you become unable to control the sander accurately and the quality starts to suffer.

Cobot sanding is made possible with precise force control. When you program the robot to apply a particular force to the surface of the wood, it will always apply that force.

7. Starts your automated future

If you haven't heard it already: automation is the future of manufacturing. This is also going to be true in cabinet door making. The sooner you get started with automation (even in a tiny way) the more likely you are to remain competitive.

Get started in the new, automated world

Investing in cobot sanding (e.g. through our Sanding Kit) is a great way to see immediate benefits with a small amount of automation.

When you give your boring sanding task to your cobot, think how much more you could achieve in your business!

What could you do with the extra time given to you by a sanding cobot? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

Leave a comment