5 Unique Features of Our Robotiq Screwdriving Demo @ Automatica 2022

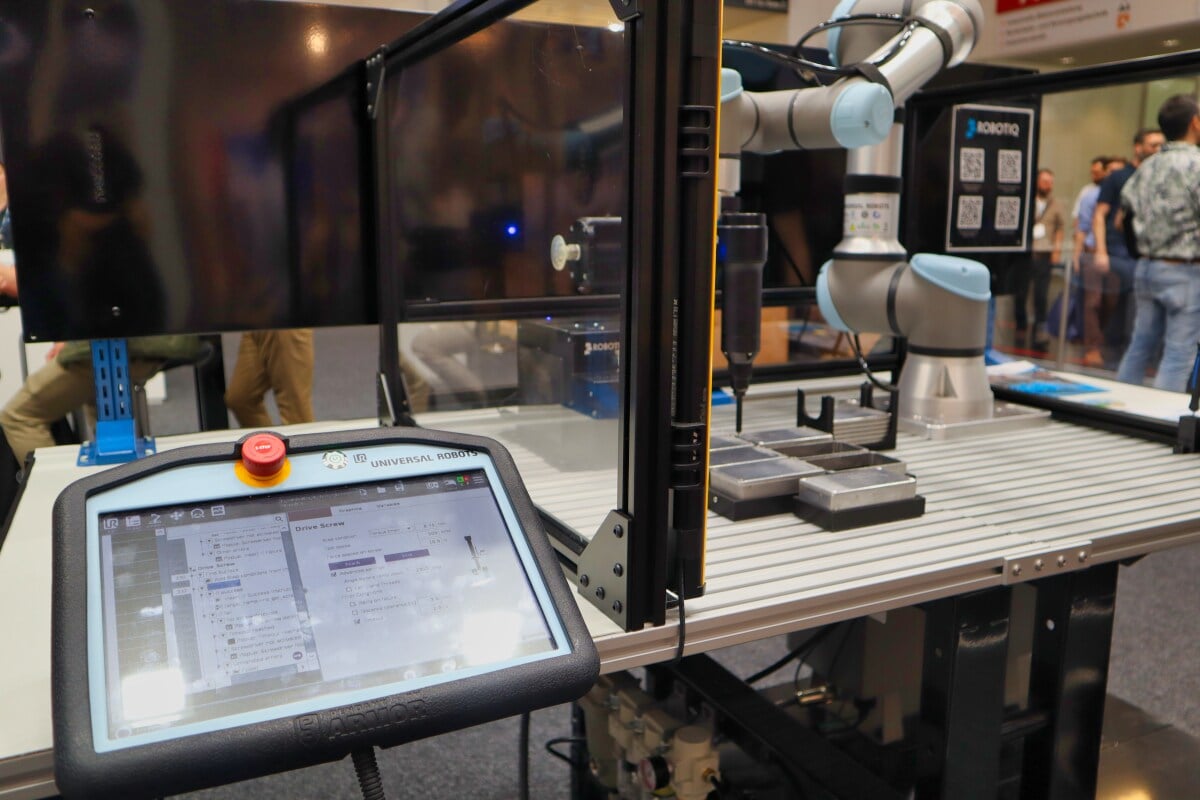

We've had a lot of keen people visiting the Robotiq booth this year. One application that is generating a lot of interest is our Screwdriving Solution.

So we decided to put together a blog post for you showcasing our Screwdriving Solution demo…

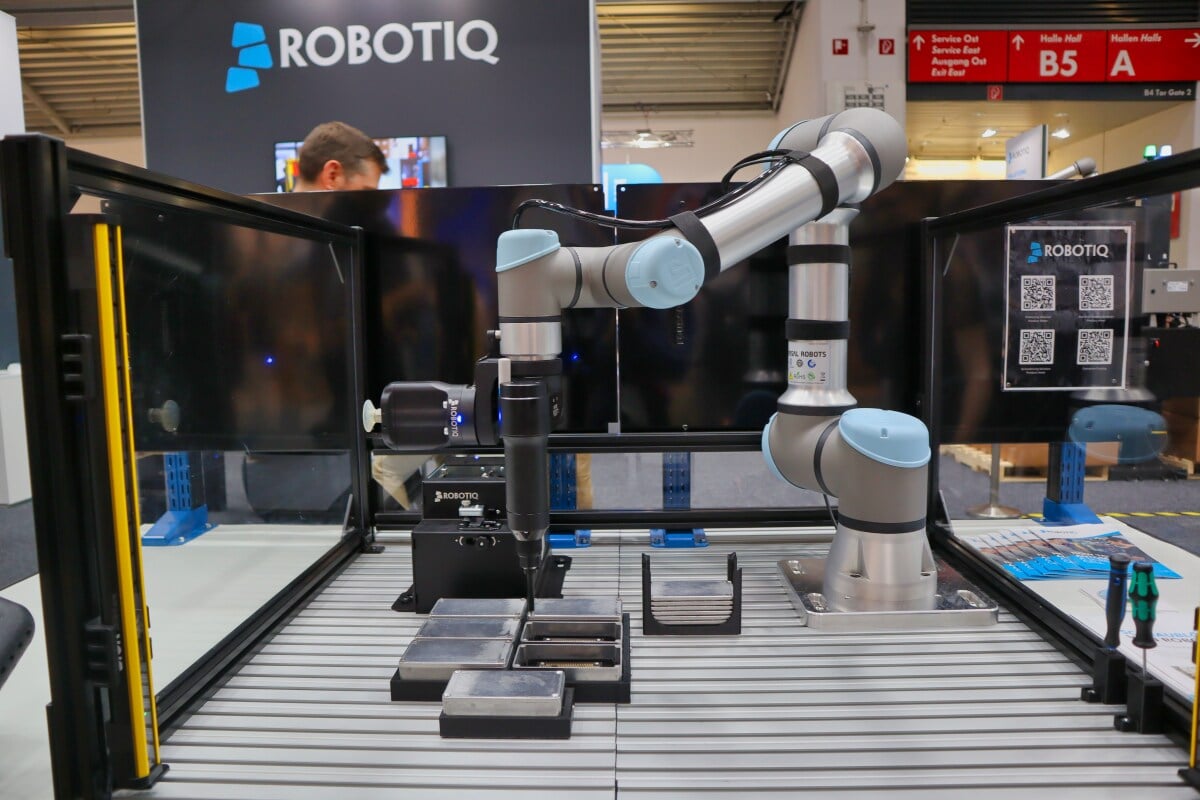

Introducing the Robotiq Screwdriving Solution

Our Robotiq Screwdriving solution is getting a lot of interested visitors here at Automatica.

We designed the solution to fix changeover issues and provide consistent screwdriving around the clock. With five minutes, you can reconfigure it for an alternate production line.

The solution comes with everything you need to deploy a screwdriving robot to your process. It comed pre-integrated for UR via the URCap, is very easy to use and offers a lot of convenience for new and experienced robot users alike.

The Robotiq Screwdriving solution is one of the most popular kits we have here at Automatica. Some of our partners in the show have even included it in their booths.

See the Screwdriving demo in action!

When you walk up to our booth at Automatica (B4.502) you are greeted by the smiling faces of our team.

Here, Robotiq's Applications Expert Élizabeth Martel explains the Screwdriving demo just for you, our blog readers…

The 5 unique features of the Robotiq Screwdriving Solution

There are some other screwdriving solutions here at Automatica. But, at Robotiq, our solution offers some unique features and benefits.

Our Screwdriving Solution is unique for several reasons:

1. Its very easy to use and configure

We know that most people don't have time to integrate and learn new technologies. With our Screwdriving Solution, you can be up and running very quickly. The application kit comes with everything you need to get started.

2. It's pre-integrated with Universal Robots

UR is one of our long time partners – we're even "booth neighbors" here at Automatica. The Screwdriving Solution is fully pre-integrated with UR via the URCap.

3. It uses pneumatics

One distinct feature of our solution compared to others you might see at Automatica is that it uses pneumatics to pick the screws. Most solutions you could find at the show use magnets.

Benefits of using pnematics to pick the screws include:

- You can use non-ferromagnetic screws (such as aluminum)

- The vacuum helps to align the screw more effectively than magnets.

- The vacuum itself is used to detect the presence of the screw, so the robot knows if it drops one.

4. Compact and lightweight

The Screwdriving Solution is very compact. It takes up a small footprint in your production line. The screwdriver is also lightweight compared to other screwdriving solutions – it's only 1.7 kg so you could even fit it onto a UR 3 robot (which only has a payload of 3 kg).

5. Unrivaled support and community

One of the things our users often comment on is how much they love the support we provide at Robotiq.

We have a team of product managers, applications experts, and customer success managers who are always on hand to help you get the most out of your Screwdriving Solution. Many are here at the Robotiq booth, so you can meet them in person!

And if you choose one of our solutions, you'll become part of our strong, supportive community. As Esben Ostergaard said in his keynote address this morning, this type of ecosystem is a core part of what makes cobots so successful for new robot users.

At Automatica? Come and check out the Screwdriving demo!

If you're looking for a versatile and easy-to-use screwdriving solution, the Robotiq Screwdriving Solution is the perfect choice for you. Come and see us at Automatica (B4.502) to see it for yourself!

Leave a comment