5 Machine Tending Problems That Vacuum Grippers Solve

Posted on Oct 03, 2019 in Robot Grippers

5 min read time

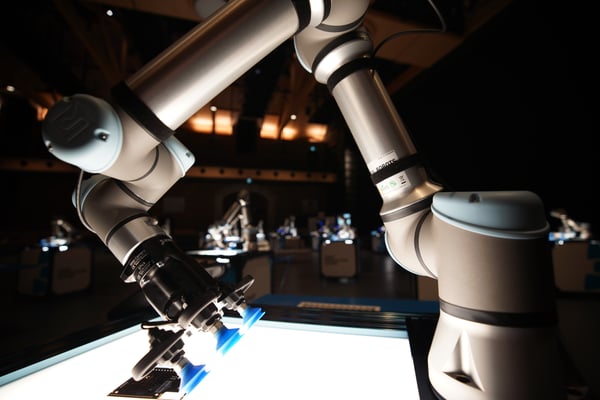

Machine tending is a very popular cobot task but it can cause problems when using a fingered gripper. Vacuum grippers can be the solution to these problems.

New users often ask us which task is best for them to try when getting started with collaborative robots. Of course, our answer is very dependent on the user's specific needs. Even taking this into account, we often recommend machine tending.

Machine tending is usually very easy to setup, easy to program, and usually an "easy win" to get the automation ball rolling in your business. But, even though machine tending is the perfect starter project, that doesn't mean it never causes problems. Sometimes the limitations of the fingered gripper can turn machine tending from an easy task into a challenging one.

Thankfully, there is another gripper that can come to the rescue: vacuum grippers!

A vacuum gripper can overcome several of the common problems and challenges that can occur when a fingered gripper doesn't perfectly suit your machine tending task.

A common misconception about robot machine tending

As the name suggests, machine tending involves using a robot to tend a machine. When implemented correctly, it entirely removes a dull and repetitive task from the hands of a human worker, allowing them to move to a more interesting, value-added task. Because of this, it is a good application to convince the workforce to accept robots onto the work floor.

The most common task is to use a robot to tend a CNC machine (a lathe, router, drill, etc). But, the popularity of this task can lead to a misconception.

Sure, CNC machines are the most common form of machine tending, but this doesn't mean they are the only compatible machines.

Machine tending is not just about CNC

The importance of vacuum grippers really becomes apparent when we start to look at other types of machine tending.

There are a huge variety of automated machines, including:

- Product testing machines

- Painting and coating machines

- Automated assembly machines

- Visual inspection machines

- and more.

Many of them are compatible with robot machine tending. Here on the blog, we've even mentioned machine tending craft beer machines, and machine tending your festive turkey in the oven.

This wide variety of tasks means that there's an even wider variety of objects and situations which need to be handled… and that's where vacuum grippers come in.

Why vacuum grippers

Vacuum grippers are one of the most popular grippers in various industries. They provide a very flexible grasping interface which can handle a wide variety of objects. They are also extremely customizable. This is one reason that they are able to handle those grasping situations which fingered grippers can struggle with.

Three of the qualities that make vacuum grippers well-suited to those problematic machine-tending tasks are:

- Quick response

- Customizable layout

- Different airflow options

Of course, some tasks will be most suited to vacuum grippers and others will be suited to fingered grippers. But, if you encounter one of those problematic edge cases, vacuum grippers could certainly help you to solve your problems.

5 machine tending problems that vacuum grippers solve

Every robot integration is different. The problems and challenges you may encounter during your own robot integration may be unique. But there are some issues that turn up more frequently than others.

Here are 5 common machine tending problems that can be solved by using vacuum grippers.

1. Small workspace

Collaborative robots are pretty small. However, some forms of automation are smaller still. Fingered grippers are usually quite big when the fingers are open which stops them from entering machines with smaller workspaces — even the smallest grippers like Hand-E.

This can be a deal-breaker in terms of machine tending. After all, if the robot can't reach inside the machine, how can it tend the machine?

Vacuum grippers offer the smallest tool size of any gripper. You can get vacuum cups which are only a few millimeters in diameter.

2. Awkward workspace

Even when the machine is big enough to fit a fingered gripper, it can sometimes be difficult to maneuver the gripper into the right position to pick up the object from within the machine.

Sometimes, this restriction can make it almost impossible to get a good grasp on the workpiece with a fingered gripper. If the two fingers can't close around a solid feature of the part, you're stuck.

Vacuum grippers do not need to approach the workpiece in any particular direction to get a good grasp on them. All they need is a flat surface to press onto.

3. No good grasp points

Some workpieces just have no good grasp features at all. For example, imagine that your robot is tending a laser engraving machine which draws designs on thin, fragile sheets of glass. A fingered gripper could struggle in this situation as there is no easy way to pick up each sheet without risking breaking it.

Vacuum grippers often "come to the rescue" in such situations because they don't need good grasp features.

4. Delicate objects

It's true that our 2-Finger grippers are very gentle. They can pick up objects and only apply a 20N force to them, which is good enough for most applications. However, it's not always gentle enough. Imagine you're using the robot to tend a cookie-icing machine. You don't want to break your cookies with the gripper, do you?

Vacuum grippers are used extensively in industries where delicate handling is vital, including healthcare, food production, and electronics. If your machine tending task requires delicate handling, a vacuum gripper could be the best option.

5. Fast cycle times

Most machine tending tasks (e.g. tending a CNC lathe) involve quite a long wait time as the machine which is being tended finishes its operation. As a result, the grasp time of the gripper doesn't have a huge effect on the overall cycle time of the robot cell.

However, with more high-speed machine tending tasks (e.g. tending an automatic labeling machine) the gripping time can have a significant effect.

Vacuum grippers do not rely on closing fingertips to pick up an object. As a result, they have one of the fastest gripping times of all grippers and can really reduce that cycle time with high-speed machine tending.

If you've got a problem with your machine tending task, the Robotiq Machine Tending Solution could be the answer that you've been looking for!

What challenges have you encountered with machine tending? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

.jpg)

Leave a comment