10 Questions to Ask Before Choosing Robotic Bin Picking

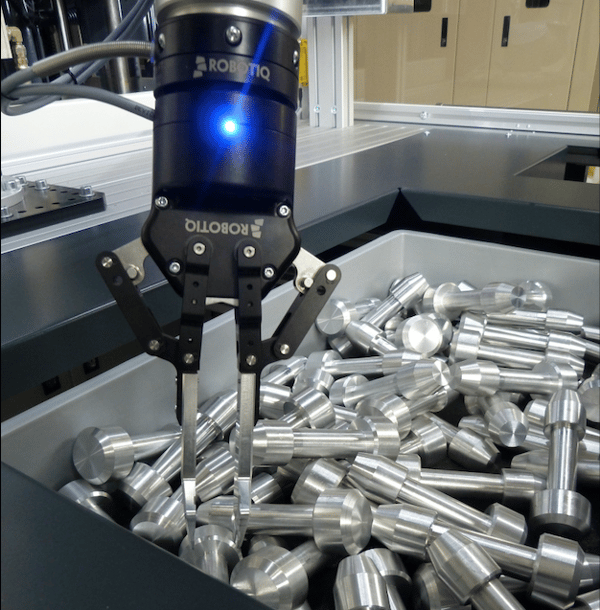

Bin picking. You might have heard that it's the next big step in robotics — an application that allows your robot to automatically detect, sort, and grasp objects that are scattered at random in a box (or bin).

There are probably several applications you can think of that would be perfect for bin picking.

But, is bin picking the right choice for you?

Or do you worry that adding a bin picking robot could be an expensive mistake?

As The Robot Report said in 2019: "The need for automated bin picking is urgent. In the U.S., where 38% of the manufacturing labor force moves parts between bins and manufacturing machines, 500,000 jobs remain unfilled. "

Many robot users see the huge need for bin picking. Without it, every item that will be handled by the robot must be carefully laid out so that the robot can access it easily.

Even with robot vision (which has become much easier to use in recent years), the robot will still find it difficult to detect objects that overlap each other — as is the case in many industrial situations.

Is bin picking the answer?

Source: romi-is.com

Robotic bin picking: Too good to be true or the next big thing?

The promise of bin picking is this: You can put down a box piled high with (known) objects and the robot will easily be able to detect the objects and pick them up.

The objects can be laid out at random, they can be jumbled on top of each other, and they can be overlapping. However they are arranged, the robot's sensor system will still be able to detect them.

But, is bin picking too good to be true?

According to some reports, the adoption of bin picking is still very low. The use of bin picking in SMEs is almost zero and it's not much higher in large manufacturing companies. This is despite the fact that many bin picking applications have been seen in trade shows and online videos for the last couple of years.

And this lack of uptake isn't surprising…

The change that has made bin picking more accessible than ever

Until recently, bin picking has been a complex proposition.

Bin picking applications traditionally required complex sensing systems, detailed models of the environment, and real-time collision-free path planning algorithms. This meant that bin picking robots were expensive and complicated to deploy.

Now, these barriers have been significantly reduced.

It is now easier than ever to add a bin picking application to your setup.

The question is no longer "Can I do bin picking?" (you can).

The question is now "Is bin picking the right choice for me right now?"

If you're considering robotic bin picking, the only thing you need to do now is to get clear on your reasons for choosing bin picking.

10 questions to ask before choosing robotic bin picking

Here are 10 questions you can use when deciding if bin picking is right for you:

1. Why am I considering robot bin picking?

First, get clear on why you think bin picking might be a good option. What led you to consider it as a solution?

Even with the new, easy bin picking solutions, you should only go ahead with bin picking if it's really the best option to solve your current problems.

2. Which business priorities does bin picking fit with?

Check that bin picking aligns with your business goals.

For example, if you are looking to increase throughput to ramp up your production output and bin picking will help you to do this, great. However, if your business priority is to increase product quality and bin picking would have no effect on this for your specific situation, look again at your reasons for considering it.

3. Which of my applications could use bin picking?

Before you make your decision about which application to deploy first, identify all the applications in your process that could be suitable for bin picking. You may find that there are multiple potential applications. For your first deployment, it's a good idea to pick one that will be relatively easy to integrate and will quickly give you a good return.

4. Will there be an acceptable ROI?

As with any robot purchase, it is important to determine what the payback time will be. You can use our free ROI Calculator to determine what will be the Return on Investment for your situation.

5. Which robots support bin picking out-the-box?

Although bin picking has become significantly easier to use recently, it is still a complex application for many robot brands. You want to make sure that your chosen robot will make life as easy for you as possible. For example, our new bin picking application kit works out-the-box with UR robots.

6. What's the best timing for deploying your bin picking robot?

Get clear on whether now is the best time to deploy your bin picking robot. If not, decide now when will be a better time.

As our CEO Samuel Bouchard wrote recently, there are a few things to consider if you are questioning whether or not now is a good time to invest in a robotic application.

7. Is bin picking absolutely necessary for your application?

Since bin picking is now much easier to use than it has ever been before, some people might consider adding it even where it is not absolutely necessary.

There's more than one way to achieve most robot applications. Is bin picking really necessary? If there is an easier way to achieve the same task, you should seriously consider it.

8. Who on your team can deploy a bin picking robot?

As robots have become easier to use, it's now possible for members of your team to deploy a robot application who might not have had the right skills in the past. This is now also the case with bin picking.

Identify which members of your team will take responsibility for deploying the robot.

9. Do you have a support network for the robot deployment?

Things are always easier when you have a support network of partners and peers who are experienced with robotics. One way to get this support is to sign up to the DoF robotics community, in which many people are experienced with robotic applications, including bin picking.

10. What's the best way to get started?

Once you have determined that robotic bin picking is the right solution for your situation, you will want to get started as easily as possible.

Contact our integration coaches who will help you to get it up and running quickly.

Which of these questions was the most helpful for you? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

Leave a comment