How to Choose the Right Mechanical Coupling for your Robotic Gripper?

Posted on Jul 30, 2014 in Robot Grippers

4 min read time

When looking for a robotic cell, a lot of factors need to be considered in order to make your cell run as fast as possible. When choosing a specific robot, a lot of different configurations can be made regarding the end effector's fixation method. In fact, most of the time when buying a specific gripper and robotic arm, they won’t match with each other. This is why most companies use mechanical couplings or adapters to be able to fix the gripper to the robot arm. This article will guide you through the different lexicon and steps to identify which Robotiq adapter plate you should use depending on your robot.

Lexicon

-

Coupling: Part that is fixed to the robot gripper and joins it with the next part of the fixation. Robotiq is using the following nomenclature to identify their couplings: AGC-CPL-XXX. AGC stands for the type of Robot Gripper, in this case Adaptive Gripper C (for 2-Finger Adaptive Gripper-85), CPL stands for coupling, and the following number (XXX) is the serial number of the coupling corresponding to a given configuration.

-

Adapter Plate: If the coupling cannot be fixed directly to the robot wrist, an adapter plate is used to pass from a smaller to a larger bolt pattern. Robotiq is using the following nomenclature to identify their couplings: AGC-APL-XXX. AGC stands for the type of Gripper, in this case the Adaptive Gripper C (for 2-Finger Adaptive Gripper-85), APL stands for adapter plate, and the following number (XXX) is the serial number of the adapter plate corresponding to a given configuration.

-

Bolt Pattern: A disposition of threaded holes to receive several screw. A bolt pattern is normally on a circular or square path and may have dowel pin holes for alignment.

-

Robot Wrist: The last joint of the robot. This part has holes (threaded or unthreaded) to receive the different alignment and fixation devices.

Peripherals

First of all, you have to figure out if you will need to change your gripper during your process or if it’s going to be the same gripper for a long period of time. If you need to change the robotic gripper during an operation, a ‘'tool changer’’ can be used. These devices allow the robot to change the end effector during the process. If you don’t need this kind of device a simple adapter plate is required.

Notice that the coupling or adapter plate will be different if you are using a tool changer or not.

Bolt pattern

As you may have noticed, the robot wrist has a specific bolt pattern. A lot of robot manufacturers are respecting the bolt pattern standard (ISO 9409-1). Though some robot manufacturers don’t respect the norm and create their own bolt patterns. This can be a real headache for the end user, because of the different nomenclature and fit.

Notice that the norms cover different aspects of the robot/tool interface, so it can be interesting to take a look at the entire section concerning Mechanical interfaces to get further information.

If the manufacturer is respecting the norm, he will include the relevant information in the technical specifications of the robot. Most of the time a representation of the bolt pattern will be shown. In some cases the ISO nomenclature will be used. To help you understand this nomenclature, see the following:

How do I know if I need an adapter plate?

It is quite simple. After you have chosen a certain robot gripper and robot wrist, you'll have enough information on the bolt patterns that you will need to fit together.

First of all, check if you can only use a single coupling by visiting the Robotiq Support Section. You'll find a detailed and regularly updated list of all the different couplings we have fabricated to fit the most common robots in use today. By comparing your robot bolt pattern and the coupling bolt pattern you will find which one suits your setup best.

However, if you cannot find a coupling that fits your robot wrist, it means you need an adapter plate to adapt the coupling to the robot wrist. Once again, visiting the Robotiq Support Section will allow you to find which one is the best for your setup.

Finally if you don’t find any of the couplings or adapter plates that match your robot wrist, contact us at support@robotiq.com to tell us what your needs are and we will be able to help you out. We can create a specific mechanical coupling for your needs.

Installation

Depending on the Robotic Gripper you will be installing, the mounting instructions will be different. First of all the adapter plate has to be install directly onto the robot wrist. Then the coupling is fixed to the adapter plate of the robot wrist (depending on the setup). Finally the Gripper is fixed to the coupling. Now everything is set and ready to work normally.

Note that Robotiq only provides screws and pins to fix the Gripper to the mechanical coupling and the adapter plate. The screws or pins that are necessary to attach the entire end effector to the robot wrist are not provided by Robotiq, but should be provided by your robot manufacturer.

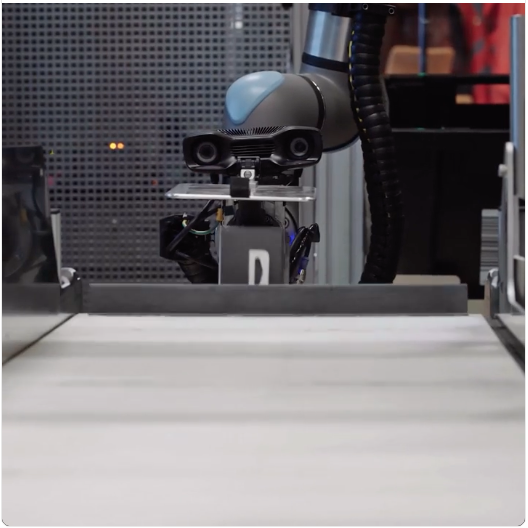

To view an example of how to install a mechanical coupling, look at the following video featuring the 2-Finger Adaptive Robot Gripper - 85 and a UR5 from Universal Robots.

We hope this article gives you a better idea on how to choose the different mechanical fixtures for your robot. Don’t hesitate to contact us at info@robotiq.com for further or more specific information on any technical topic.

.jpg)

Leave a comment