Is an electric robot gripper always a servo gripper?

Posted on Jan 14, 2014 in Robot Grippers

3 min read time

Electric grippers or servo grippers are most of the time used as synonymous. Are they really the same thing? An electric gripper simply means that the power provided to its actuator is electricity. Electric is used to differentiate it from pneumatic, which is still the most widely used in the vast majority of industrial applications to power robotic grippers.

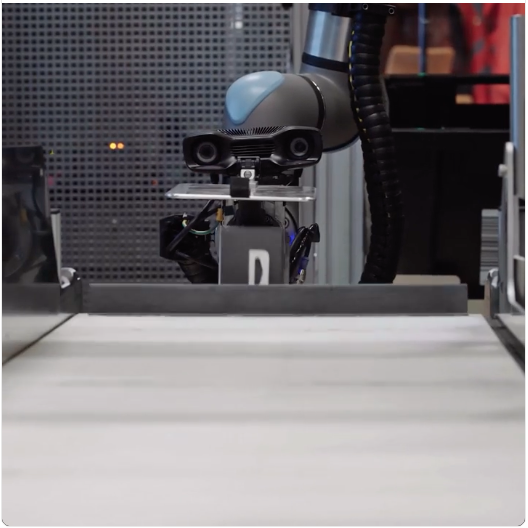

The Robotiq Adaptive Gripper (here shown on a Universal Robot) is

one example of a servo gripper with mechanically intelligent fingers.

Some electric grippers mimic the simple open-close behaviour of pneumatic grippers. Their actuators are usually on-off devices such as solenoids. Is an electric robot gripper always a servo gripper? In fact, servo grippers are a subcategory of electric grippers. A servo gripper, just like a servo motor, can be closed-loop controlled to achieve more evolved behaviours than simply opening and closing. A servo gripper can be seen as a servo motor driving a gripping mechanism.

How to choose an electric robot gripper?

If your goal is simply to get rid of air, using an electric gripper with an open-close feature might do the work. If you need more precise control on position, speed, or force and have a wider stroke range to cover, a servo-gripper is really what you need. We've previously discussed the advantages of servo grippers over pneumatic grippers. Let's say you've decided to use an electric gripper, you'll obviously have to define all the usual gripper requirements.

- Stroke

- Grip force

- Gripper jaw design

- Speed

- Weight

- Environmental protection

- Reliability

- Cost

On top of that, you'll want to compare the different features that come specifically from the electrical actuation.

- What gripper parameters need to be controlled?

Controlling the jaw position is great for handling a wide range of parts without compromising the cycle time. Force control is necessary to handle fragile parts. Controlling the speed is useful when a large capacity gripper also needs to pick light parts that can fly away if the speed is too high.

- What feedback do you need from the gripper?

What needs to be measured at the gripper to ensure that the robotic cell works at its best? To detect a part, a sensor is usually added to the pneumatic gripper. That feature is often built into the servo gripper. Some servo grippers, including the Adaptive Grippers, also give you feedback on the jaw position and current in the motor.

- How will the gripper interface with your robot?

What electric power needs to be provided to the gripper? How to communicate back and forth with the gripper? Some use discrete IOs, others communicate over industrial buses. Industrial buses can usually allow for more information going back and forth and a more precise control on the different parameters. But you need to make sure that both the robot and the gripper are compatible. Like a servo motor, a controller is usually needed. It can be external or embedded in the gripper.

So pneumatic or electric? The challenge of the use you require will usually dictate which type of gripper you will need, but often electric grippers can preform more functions and are therefore useful in applications requiring more flexibility.

Leave a comment