What's the Best Way to Apply Food Processing Automation?

Posted on Jan 11, 2022 in Automation

5 min read time

You want to start using automation for your food processing process… but what is the best way to start using the technology?

There are various benefits of using automation in food processing including increased productivity, better use of human workers, and improved process efficiency. Food companies are increasingly automating their processes to stay competitive.

But, the food industry has tended to lag behind other industries when it comes to adopting automation.

Why is the industry behind and how can your company stay ahead of the curve?

Here's an introduction on how to get started with food processing automation…

What is food processing automation?

Food processing automation refers to any type of technology that helps to reduce the human input in food processing tasks. Examples range from simple machines that dispense food products into their packaging all the way to completely automated kitchens with "robot chefs."

There are many types of automation in the food industry and some have been used for decades. Most modern food products have been handled by at least some form of automation.

If automation is so common, why is the industry lagging behind?

There have been changes recently in both the food industry and automation technology. Automation is now more accessible to smaller food processing companies than it ever was before. Although automation is common in very high-volume processes, it has been traditionally been out of the reach of smaller companies.

When you look at the industry as a whole, automation is still much less common than it is in other manufacturing industries.

Why is the food processing industry lagging with automation?

According to Food Processing magazine adoption of automation is much lower than you would expect, despite the benefits it can bring to manufacturers.

This lack of adoption is likely the result of several interrelated factors, including:

- Uncertainty from food processing companies about the new technology.

- Inertia, especially in a fast-moving industry like food processing.

- The "get it out the door" mentality in the industry that conflicts with the long-term investment of automation.

- Resistance to change from leaders and workers in the industry.

- Desire to avoid downtime and increased worker training.

Such barriers can lead food processing companies to put off automation "until another time." Unfortunately, this way of thinking can leave otherwise forward-thinking companies far behind their competitors.

Automation is growing in the industry

Despite this resistance to automation, there are clear signs that food and beverage companies are increasingly embracing automated technology.

What does this mean for companies like yours?

It means that you need to seriously think about how you can incorporate more automation into your processes. Otherwise, your company will be one of the ones left behind!

Food processing robots and how they overcome the challenges

Thankfully, there is a type of technology that can reduce the pressure when incorporating automation for the first time.

Robots are flexible and can be applied to many more areas of the food processing workflow than more conventional forms of automation. Robots can also achieve many more tasks than they could before. Applications that were previously very experimental are now close to being commercially viable.

Collaborative robots are a highly accessible form of robotic automation. Even smaller food processing companies can take advantage of them.

Recent developments that increase the utility of collaborative robots in food processing include:

- Off-the-shelf application kits that allow you to deploy a robot quickly and easily.

- Simplified programming interfaces that almost anyone can use.

- More delicate gripping technologies that can handle a wider range of food products.

These robots don't remove human workers from the picture completely. Instead, they are used to take over those lower-value tasks in the food production process, freeing up workers to carry out more value-added tasks.

You can see an example of this in action in this noodle shop demonstration. It uses collaborative robots to cook the noodles (a less value-added task) and human workers for the more complex tasks:

How to automate a food production process with robots

If you want to improve your food processing by adding a collaborative robot, where should you start?

Examples of good first tasks for food processing include:

- Packing processes, of which there are many in food processing.

- Pick and place of either packaged or unpackaged food products.

- Machine tending of semi-automated food processing machines.

- Quality testing and inspection.

Here are some steps that will make the deployment run smoothly:

- Identify some tasks that you could automate with the robot and narrow it down to one main task. This should ideally be a non-value-added, repetitive task that people don't like to perform.

- Where possible, pick a first task that has an available robotic application kit or solution. This can significantly reduce the task of deployment.

- Test your robot cell under a range of different situations to ensure the deployment is robust (e.g. with different product lines and throughput rates).

- Collect data continuously and use this to improve the robot deployment over time.

- When you have demonstrated that the first application is a success, begin looking for another application you could deploy.

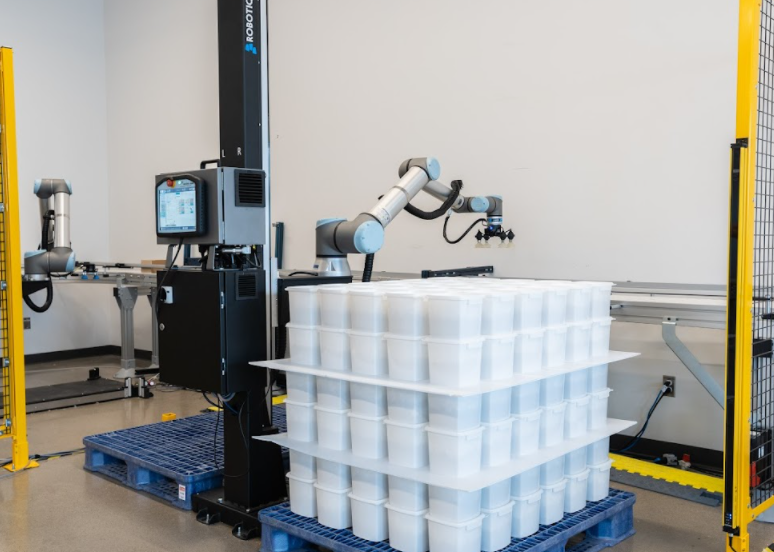

Palletizing: A safe bet with food automation

What if you are still uncertain about robotics? You likely want to get started with a very easy, highly useful task that will have a clear return.

Palletizing is a very popular robotic task in the food industry… and with good reason. Almost every food processing facility requires both palletizing of packaged products and depalletizing of raw materials.

It is also a task with a much longer track record in the food industry than other types of automation. For a long time, automation in the food industry has primarily been focused on the packaging area. Robotic palletizing is a well-proven task.

You can learn more about robotic palletizing on the application page.

What has held you back from using robots in the past? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment