Top 3 reasons to automate your small-medium enterprise

Posted on Nov 10, 2015 in Automation

4 min read time

As a small-medium enterprise you probably ask yourself how you could increase your margin, increasing your production and reduce your cost? Well, this is the struggle of everybody in this size enterprise. Most of the time, you will have a product that is unique or which will add value to another major manufacturer. However, to make your way in the market; you need to increase your production, reduce your cost and enhance your product quality. Well, a part of the solution might be robots.

In fact, most of the SME's we have visited have all been stuck with the same problems: workforce is hard to find, production is going to fast for the number of workers, so quality is suffering. Well, introducing a collaborative robot like Universal Robots into your manufacturing process can help you solve these problems.

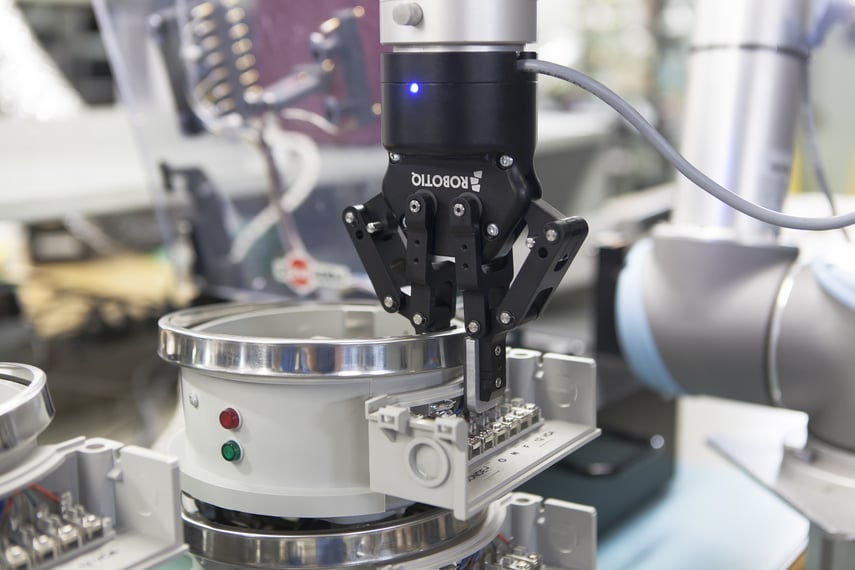

** The video features a Universal Robots UR5 and a Robotiq 2-Finger 140 Adaptive Gripper **

In fact, here are 3 reasons why you should automate your manufacturing process with a collaborative robot.

1. Saving $$$

Collaborative robots have a very fast return on investment (ROI). In fact, most of the people who will introduce a collaborative robot into their production line will refund it in less than 6 months. So as you are struggling with workforce problems a robot can be a cheap option to cover the lack of people. It can be placed in almost any working post that requires dexterity or repetitive tasks. You can then leave the robot run on its own and let your employee add value to the product by doing setups and quality inspections instead of standing in front of the machine all day.

2. Quality +++

A product’s quality reflects the reputation of the company. If you are delivering poor quality product, your customers will certainly hesitate to buy your product again. On the other side, if you deliver good quality product, you will be able to build a strong network of customers and they will refer others to you. You can achieve this quality by having a constant process. If the robot is tending a machine or pick-and-placing parts on a conveyor, this is time that can be repurposed for quality checks.

** A collaborative robot doing product testing on a batch of electronic components**

** A collaborative robot doing product testing on a batch of electronic components**

3. Production +++

Reducing time spent in front of the machine means time to prepare the next changeover. This also means your machine will be stopped a minimal amount of time and you will be back in production in the blink of an eye. You will then be increasing your production rate without any major changes to your enterprise.

Notice that some manufacturers will use several robots on rolling stations, so they can move them around the plant. Because of the ease of programming for collaborative robots, it is sometimes even easier to re-teach points than to find the program for the next job.

You must be asking yourself ? “What’s the price of this incredible solution?'' Well, remain calm. Here it goes.

Universal Robots depending of the model will be around $35,000 USD. A tool like the Robotiq's 2-Finger 85 Adaptive Gripper will be around $5,000 USD, then you will need to add a couple of fixtures and other components to your cell to adapt it to your application for an average total of around $50,000 USD. Notice that no additional safety devices are required to install with a collaborative robot. These robots are safe to work around humans under certain conditions and, of course, a risk assessment is must be properly completed.

With cobots you enhance your product quality, your production is a lot faster and a lot of employees stop doing redundant (and exhausting) tasks, while your return on investment is quite fast. This is why at this price it's not long before you are looking for other places to install your next robot.

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment